Water-based paint for smoking rooms and preparation method of water-based paint

A water-based paint and smoking room technology, applied in the field of paint, can solve problems such as yellowing and discoloration, and achieve the effects of improving weather resistance, reducing surface energy, and increasing contact angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

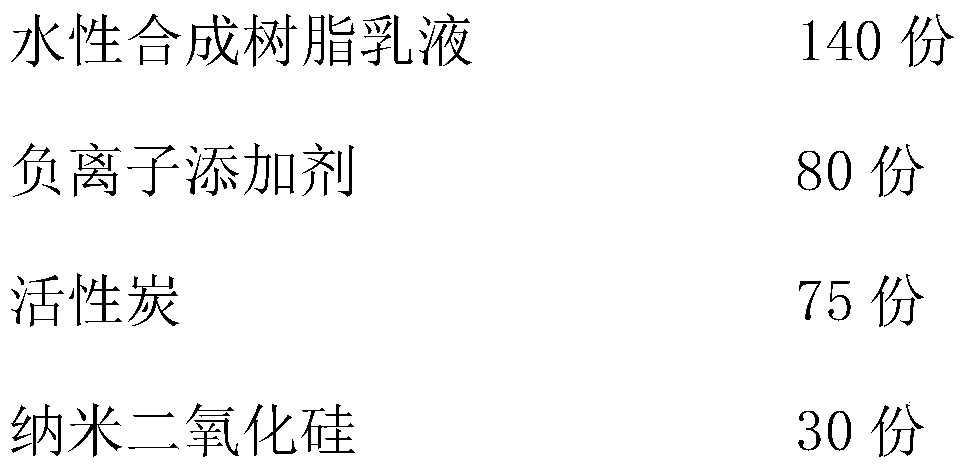

[0033] A kind of water-based paint for smoking room, in parts by mass, comprises the following components:

[0034]

[0035]

[0036] Preparation:

[0037] (1) Slowly add deionized water, thickener, wetting and dispersing agent, bactericide, pH regulator, film-forming aid and defoamer into the reaction tank and mix, and stir at a speed of 500r / min for 20min until uniform ;

[0038] (2) Slowly add pigments and fillers, negative ion additives, activated carbon, nano-silica, and micron-sized matting powder to the reaction tank in sequence, increase the dispersion speed to 800r / min, and stir for 30 minutes until the paint slurry is uniform to a fineness ≤ 50um;

[0039] (3) Slowly add the water-based synthetic resin emulsion to the reaction tank, stir for 1-5min, measure the initial viscosity, slowly add thickener according to the initial viscosity, and adjust the viscosity to Stormer viscosity 80-100KU (ambient temperature 25°C). That is to obtain a water-based paint for ...

Embodiment 2

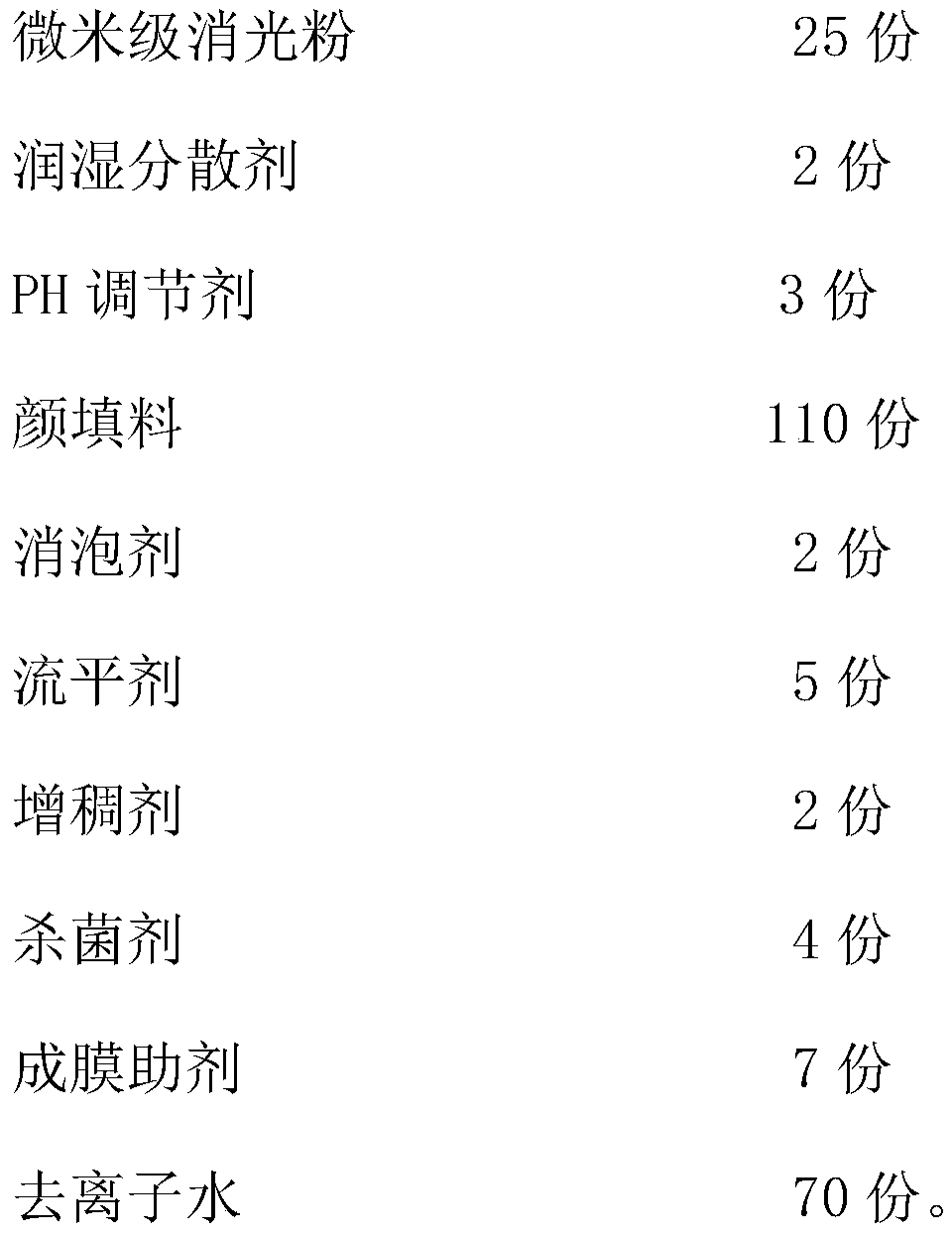

[0041] A kind of water-based paint for smoking room, in parts by mass, comprises the following components:

[0042]

[0043] Preparation:

[0044] (1) Slowly add deionized water, thickener, wetting and dispersing agent, bactericide, pH regulator, film-forming aid and defoamer into the reaction tank and mix, and stir at a speed of 550r / min for 15min until uniform ;

[0045] (2) Slowly add pigments and fillers, negative ion additives, activated carbon, nano-silica, and micron-sized matting powder into the reaction tank in sequence, increase the dispersion speed to 900r / min, and stir for 15 minutes until the paint slurry is uniform to a fineness ≤ 50um;

[0046] (3) Slowly add the water-based synthetic resin emulsion into the reaction tank, stir for 3 minutes, measure the initial viscosity, slowly add thickener according to the initial viscosity, adjust the viscosity to Stormer viscosity 80-100KU (ambient temperature 25°C), and obtain a A water-based paint for smoking rooms....

Embodiment 3

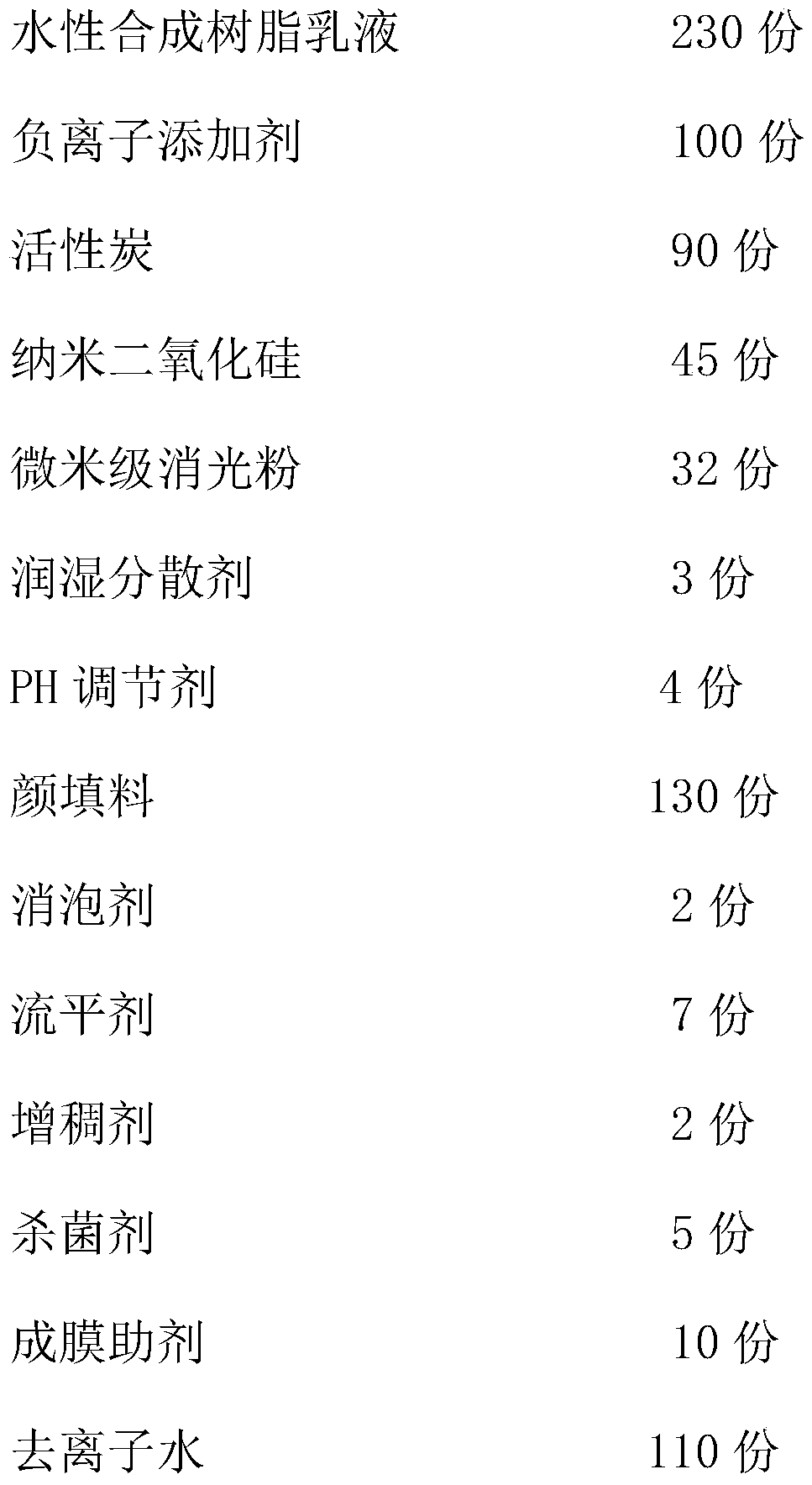

[0048] A kind of water-based paint for smoking room, in parts by mass, comprises the following components:

[0049]

[0050] Preparation:

[0051] (1) Slowly add deionized water, thickener, wetting and dispersing agent, bactericide, pH regulator, film-forming aid and defoamer in the reaction tank and mix, and stir at a speed of 600r / min for 2min until uniform ;

[0052] (2) Slowly add pigments and fillers, negative ion additives, activated carbon, nano-silica, and micron-sized matting powder to the reaction tank in sequence, increase the dispersion speed to 1000r / min, and stir for 1min until the paint slurry is uniform to a fineness ≤ 50um;

[0053] (3) Slowly add the water-based synthetic resin emulsion to the reaction tank, stir for 1-5min, measure the initial viscosity, slowly add thickener according to the initial viscosity, and adjust the viscosity to Stormer viscosity 80-100KU (ambient temperature 25°C), that is Get a water-based paint for smoking rooms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com