Thin film transistor and manufacturing method thereof

A technology of thin-film transistors and bottom gates, which is applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effects of improving panel PPI, high electron mobility, device stability, and reducing device footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

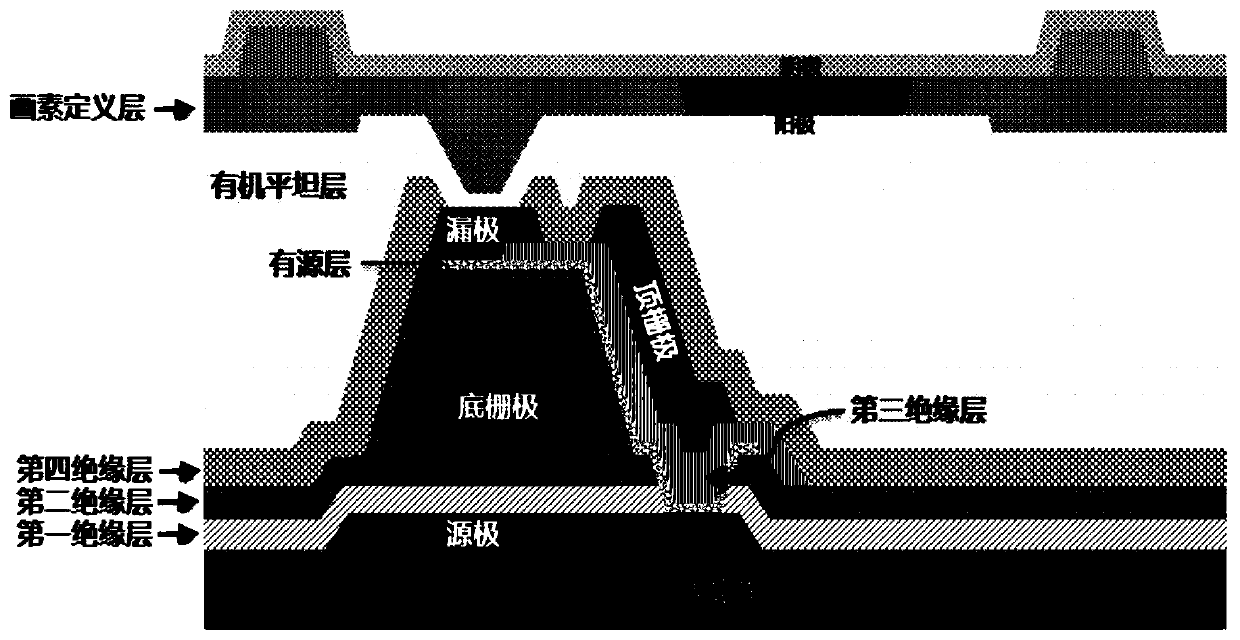

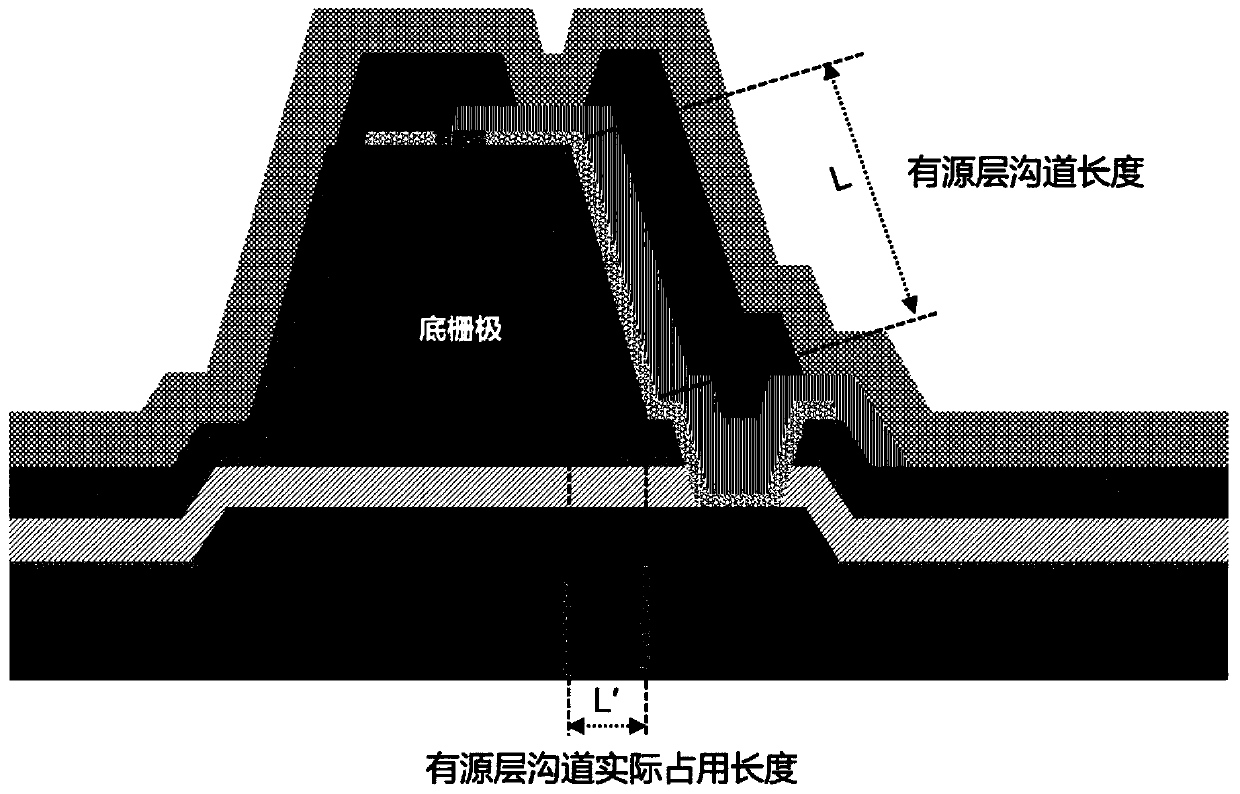

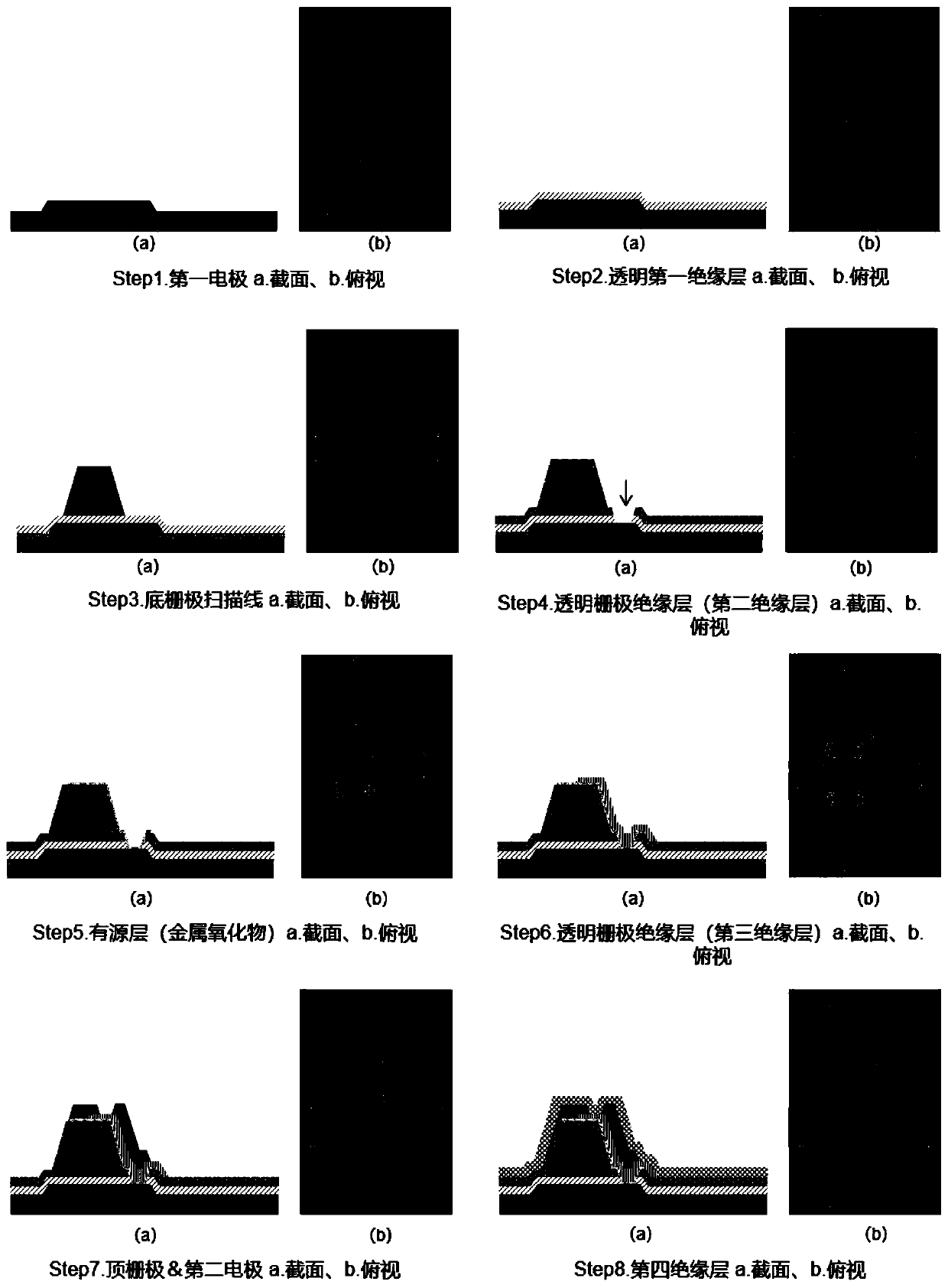

[0024] figure 1 A schematic diagram of the structure of a thin film transistor and an OLED panel thereon according to the present invention is shown, which involves a thin film transistor with a vertical structure, and the vertical structure refers to a transistor structure in which an active layer channel is formed on the side of the gate, In some existing technical solutions, the vertical structure is simplified to a "冂"-shaped structure outside the gate, which is also the origin of the name of the vertical structure. figure 2 Introduced the benefits of the vertical structure, we can see that the active layer can actually be in a range of 30°-90° oblique angle, really designed to be completely vertical is not conducive to the stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com