Wide color gamut backlight source for display of LED combined with perovskite quantum dot glass-ceramics

A technology of glass-ceramics and quantum dots, which is applied in the field of backlight, can solve the problems of performance aging, narrow luminous spectrum, and low lifespan, and achieve the effect of performance improvement and high luminous quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

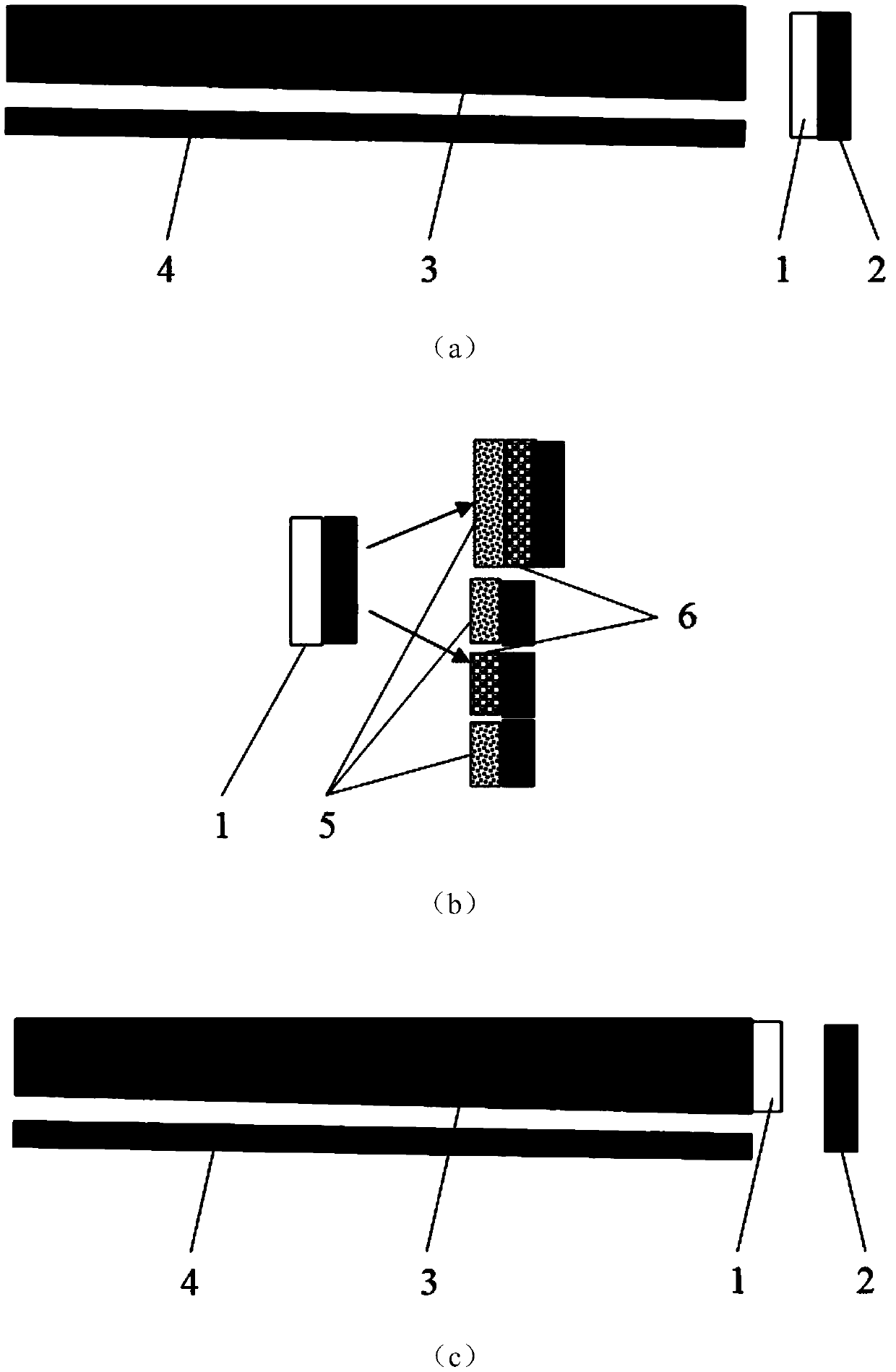

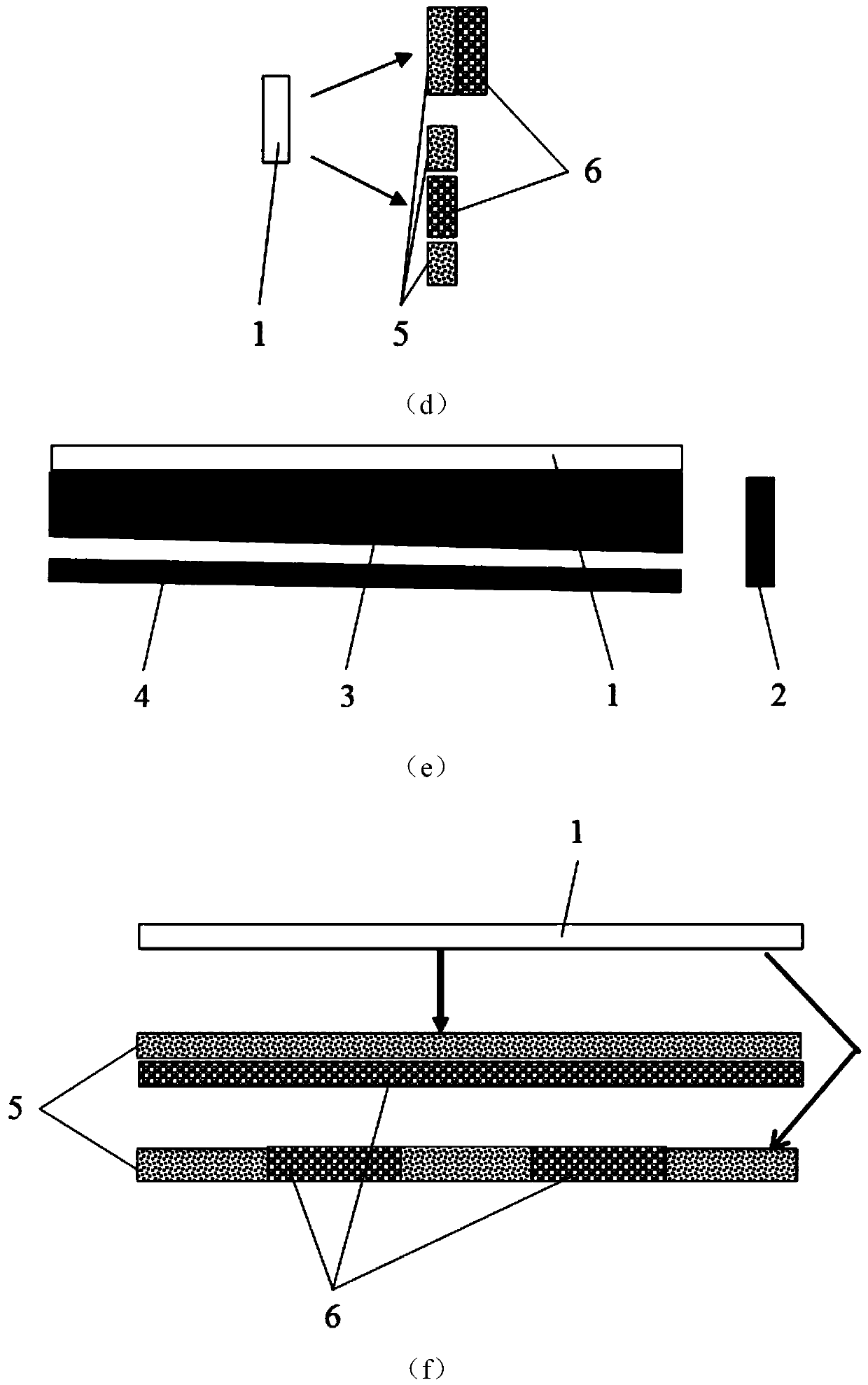

[0046] figure 2It is a schematic diagram of three applications of LED quantum dot glass-ceramic side-entry backlight in the present invention, wherein (a) is perovskite quantum dot glass-ceramic packaged on the LED chip, (b) is the LED of (a) and The enlarged view of the quantum dot glass, (c) is the perovskite quantum dot glass ceramics packaged on the side of the light guide plate, (d) is the enlarged view of the quantum dot glass in (c), (e) is the perovskite quantum dot micro The crystal glass is packaged on the back surface of the light guide plate, and (f) is an enlarged view of the quantum dot glass in (e). The side-lit backlight includes perovskite quantum dot glass-ceramic 1, blue LED 2, light guide plate 3 and reflector 4. It is required to generate red, green and blue three-color mixed light, and then pass liquid crystal light on each pixel. Valves and color filters work together to control the ratio of output red, green, and blue light.

[0047] Such as figure...

Embodiment 2

[0049] image 3 It is a schematic diagram of the application of LED quantum dot glass-ceramic direct-lit backlight in the present invention. Such as image 3 As shown, the direct-type backlight includes blue LED2, reflector 4, green perovskite quantum dot glass-ceramic 5, red perovskite quantum dot glass-ceramic 6, diffusion film 7, brightness enhancement film 8, double-increasing The bright film 9 and the LCD panel 10 with built-in color filters are required to generate red, green and blue three-color mixed light, and then control the output of red light, The ratio of green light to blue light.

[0050] Such as image 3 As shown, the direct-type backlight is suitable for perovskite quantum dot glass-ceramic 1 to be packaged on the LED chip. In order to prevent performance degradation caused by temperature rise, a reasonable thermal design is required. LED chip and green perovskite quantum-dot glass-ceramic There can be a certain distance between 5 and the glass-ceramics 6...

Embodiment 3

[0052] Figure 4 It is a schematic diagram of field sequence LED backlight application of perovskite quantum dot glass-ceramics in the present invention, wherein (a) is a blue LED combined with red perovskite quantum dot glass-ceramics and green perovskite quantum dot crystallite Schematic diagrams of red light, green light and blue light produced by glass and blue LED itself, respectively. Schematic diagrams of perovskite quantum dot glass-ceramics respectively generating red, green and blue light for field sequential display. (c) is a schematic diagram of sequentially flashing red, green and blue light to form a video field in field sequential applications. The field sequential LED backlight includes blue LED2, green perovskite quantum dot glass-ceramics 5, red perovskite quantum dot glass-ceramics 6 and blue perovskite quantum dot glass-ceramics 11, where the blue LED2 can also be LEDs shorter than the quantum dot absorption cutoff wavelength. Such as Figure 4 As shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fwhm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com