A flux cored wire

A technology of flux-cored welding wire and powder, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as lower labor efficiency, poor anti-porosity, and porosity defects, so as to enhance anti-porosity ability and reduce Pore content, effect of improving anti-porosity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

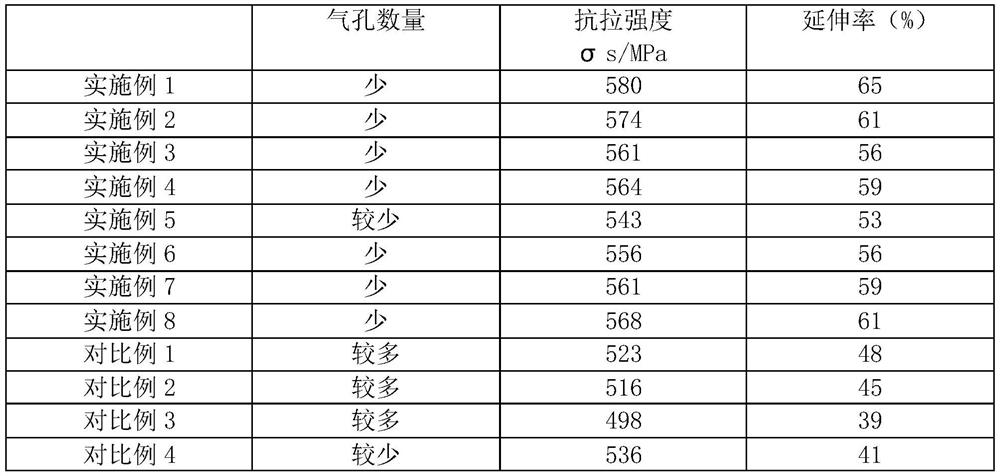

Examples

Embodiment 1

[0032] Embodiment 1 is a flux-cored welding wire disclosed in the present invention, including a steel strip and a powder filled inside the steel strip. The components of the powder and its mass percentage in the total powder are as follows: rutile 42%, limestone 6.5% , graphite 0.47%, alumina 7.1%, magnesium-aluminum alloy 4.3%, fluoride 3%, silicon-manganese alloy 1.7%, boron powder 5.5%, chromium powder 4%, nickel powder 2.85%, titanium powder 1.2%, aluminum powder 0.83 %, niobium powder 0.18% and iron powder 20.87%;

[0033] The silicon-manganese ratio in the silicon-manganese alloy is 1:3.5;

[0034] Fluoride as CaF 2 Mixtures with LiBaF;

[0035] The mass percentage of the powder in the total amount of welding wire is 17.5%;

[0036] The pretreatment step of the medicinal powder is as follows: mixing and granulating the raw materials of the medicinal powder, sintering at 750°C for 15 minutes, and then pulverizing it into fine powder, and the mesh number of the fine po...

Embodiment 2

[0038]Embodiment 2 is a flux-cored welding wire disclosed by the present invention, which includes a steel strip and powder filled inside the steel strip. The components included in the powder and their mass percentages in the total powder are as follows: rutile 44%, limestone 7.5% , graphite 0.56%, alumina 8.2%, magnesium aluminum alloy 5.5%, fluoride 4.5%, silicon manganese alloy 2.5%, boron powder 6.8%, chromium powder 5.3%, nickel powder 3.35%, titanium powder 1.7%, aluminum powder 1.25% %, niobium powder 0.38% and iron powder 8.46%;

[0039] The silicon-manganese ratio in the silicon-manganese alloy is 1:3.5;

[0040] Fluoride is CaF 2 Mixture with LiBaF;

[0041] The mass percentage of medicinal powder in the total amount of welding wire is 17.5%;

[0042] The pretreatment steps of the medicinal powder are as follows: mixing and granulating the raw materials of the medicinal powder, sintering at 750°C for 15 minutes, and then pulverizing into a fine powder with a mesh...

Embodiment 3

[0044] Embodiment 3 is a flux-cored welding wire disclosed by the present invention, which includes a steel strip and powder filled inside the steel strip. The components included in the powder and their mass percentages in the total powder are as follows: rutile 35%, limestone 5% , graphite 0.4%, alumina 5.5%, magnesium aluminum alloy 3.5%, fluoride 2%, silicon-manganese alloy 1.6%, boron powder 4%, chromium powder 3%, nickel powder 2.5%, titanium powder 0.8%, aluminum powder 0.5% %, niobium powder 0.1% and iron powder 36.1%;

[0045] The silicon-manganese ratio in the silicon-manganese alloy is 1:3.5;

[0046] Fluoride is CaF 2 Mixture with LiBaF;

[0047] The mass percentage of medicinal powder in the total amount of welding wire is 17.5%;

[0048] The pretreatment steps of the medicinal powder are as follows: mixing and granulating the raw materials of the medicinal powder, sintering at 750°C for 15 minutes, and then pulverizing into a fine powder with a mesh size of 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com