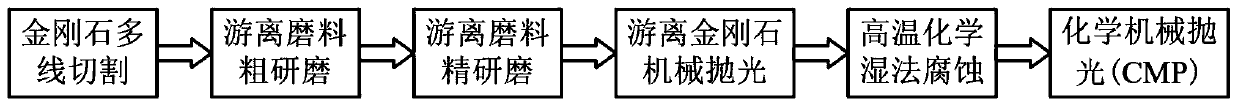

Processing method of thin plate-shaped sapphire wafer

A sapphire wafer and plate-shaped technology, applied in metal processing equipment, manufacturing tools, grinding devices, etc., can solve problems such as poor surface shape, achieve fast processing efficiency, reduce costs, and improve utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

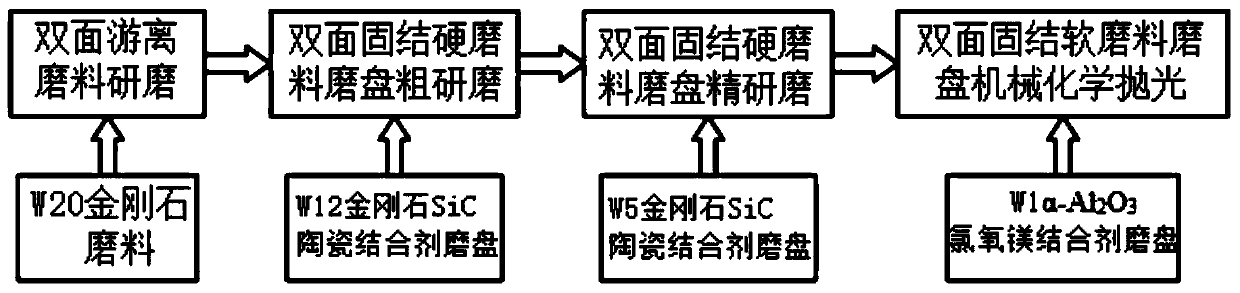

[0066] Such as figure 2 Shown, a kind of processing method of thin plate-shaped sapphire wafer has the following steps:

[0067] S1, double-sided free abrasive grinding:

[0068] First, fully mix W20 diamond micropowder and deionized water at a mass ratio of 1:15 to 1:20, and stir continuously with a magnetic stirrer to maintain a suspension state to obtain a grinding liquid; the material of the upper grinding disc and the lower grinding disc is HT250 gray cast iron. The thin plate-shaped sapphire wafer is placed in the planetary wheel groove of the constant pressure double-sided grinding machine, and the grinding liquid is continuously injected by the peristaltic pump and the internal flow channel of the grinding machine. The upper and lower surfaces of the plate-shaped sapphire wafer; the rotation speed of the upper grinding disc is 15r / min, the rotation speed of the lower grinding disc is 30r / min, the grinding pressure is 0.05MPa, the flow rate of the grinding liquid is ...

Embodiment 2

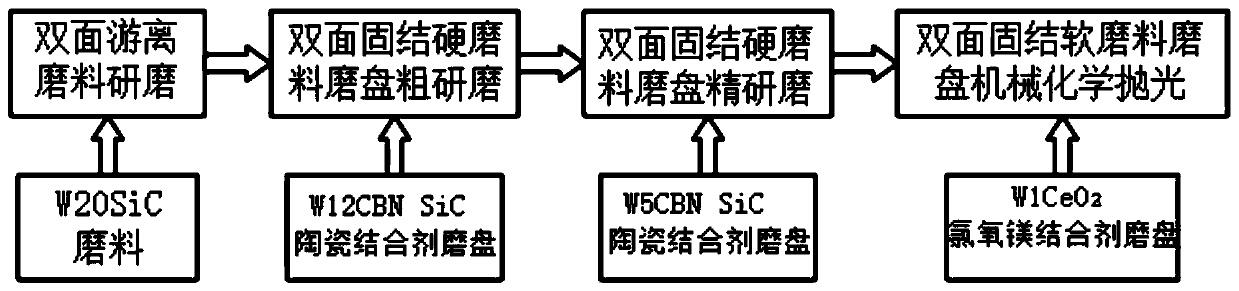

[0077] Such as image 3 Shown, a kind of processing method of thin plate-shaped sapphire wafer has the following steps:

[0078] S1, double-sided free abrasive grinding.

[0079]First, fully mix W20 SiC micropowder and deionized water at a mass ratio of 1:15 to 1:20, and stir continuously with a magnetic stirrer to maintain a suspension state to obtain a grinding liquid; the material of the upper grinding disc and the lower grinding disc is HT200 gray Cast iron; thin plate-shaped sapphire wafers are placed in the star wheel groove of the constant pressure double-sided grinding machine, and the grinding liquid is continuously injected by the peristaltic pump and the internal flow channel of the grinding machine. Flow to the upper and lower surfaces of the thin plate-shaped sapphire wafer; the speed of the upper grinding disc is 10r / min, the rotational speed of the lower grinding disc is 25r / min, the grinding pressure is 0.03MPa, the flow rate of the grinding liquid is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com