Graphene-based printing ink and preparation method thereof

A printing ink and graphene-based technology, applied in the field of graphene-based printing ink and its preparation, can solve the problems of poor dispersion effect, easy agglomeration of nano-silver, easy to fall off, etc., to achieve enhanced adhesion and tear resistance, Effect of improving electrical conductivity and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

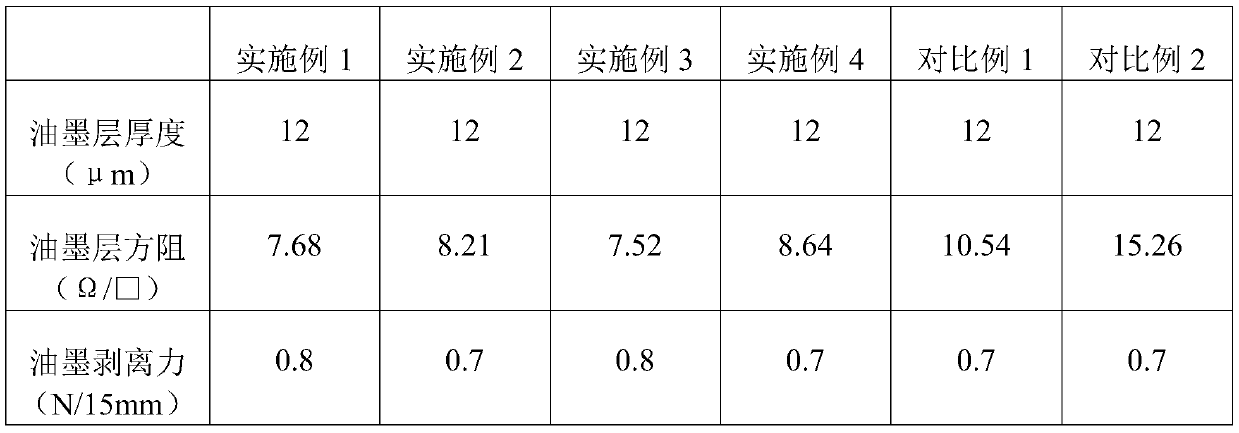

Examples

Embodiment 1

[0031] The preparation method of modified graphite flakes comprises the following steps:

[0032] 1) Take flake graphite according to the ratio of 1g / 80mL and add it to concentrated sulfuric acid with a mass concentration of 70% in a water bath and heat it to 65°C for soaking for 40min; Potassium acid potassium was added to concentrated sulfuric acid, and oxidized under airtight conditions for 8 hours. After cooling, an aqueous solution of hydrogen peroxide with a mass concentration of 20% was added. The mass ratio of hydrogen peroxide to graphite flakes was 1:20. Stir for 50 minutes and use after suction filtration. Aqueous hydrochloric acid solution with a mass concentration of 10% is pickled, washed with water, and dried at 50°C to obtain graphene oxide;

[0033] 2) Allyl glycidyl ether is dissolved in deionized water to prepare an allyl glycidyl ether solution with a mass concentration of 15%; graphene oxide is added to the allyl glycidyl ether solution, wherein graphene o...

Embodiment 2

[0042] The preparation method of modified graphite flakes comprises the following steps:

[0043] 1) Take flake graphite according to the ratio of 1g / 80mL and add it to concentrated sulfuric acid with a mass concentration of 70% in a water bath and heat it to 60°C for soaking for 50min; Potassium acid potassium was added to concentrated sulfuric acid, and oxidized under airtight conditions for 6 hours. After cooling, an aqueous solution of hydrogen peroxide with a mass concentration of 20% was added. The mass ratio of hydrogen peroxide to graphite flakes was 1:20. Stir for 30 minutes and use after suction filtration. Aqueous hydrochloric acid solution with a mass concentration of 10% is pickled, washed with water, and dried at 50°C to obtain graphene oxide;

[0044] 2) Allyl glycidyl ether is dissolved in deionized water to prepare an allyl glycidyl ether solution with a mass concentration of 15%; graphene oxide is added to the allyl glycidyl ether solution, wherein graphene o...

Embodiment 3

[0053] The preparation method of modified graphite flakes comprises the following steps:

[0054] 1) According to the ratio of 1g / 80mL, take flake graphite and add it to 70% concentrated sulfuric acid with a mass concentration of 70% in a water bath and heat it to 62°C for soaking for 45min; Potassium acid potassium was added to concentrated sulfuric acid, oxidized under airtight conditions for 10 hours, after cooling, an aqueous solution of hydrogen peroxide with a mass concentration of 20% was added, the mass ratio of hydrogen peroxide to flake graphite was 1:20, stirred for 40 minutes, and used after suction filtration Aqueous hydrochloric acid solution with a mass concentration of 10% is pickled, washed with water, and dried at 50°C to obtain graphene oxide;

[0055] 2) Allyl glycidyl ether is dissolved in deionized water to prepare an allyl glycidyl ether solution with a mass concentration of 15%; graphene oxide is added to the allyl glycidyl ether solution, wherein graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com