Fish meal preparation process

A preparation process, fishmeal technology, applied in food science, food preservation, animal feed, etc., can solve the problems of quality decline, unfavorable, prolonging the shelf life of fishmeal, etc., to achieve the effect of improving the health of the body and improving the antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

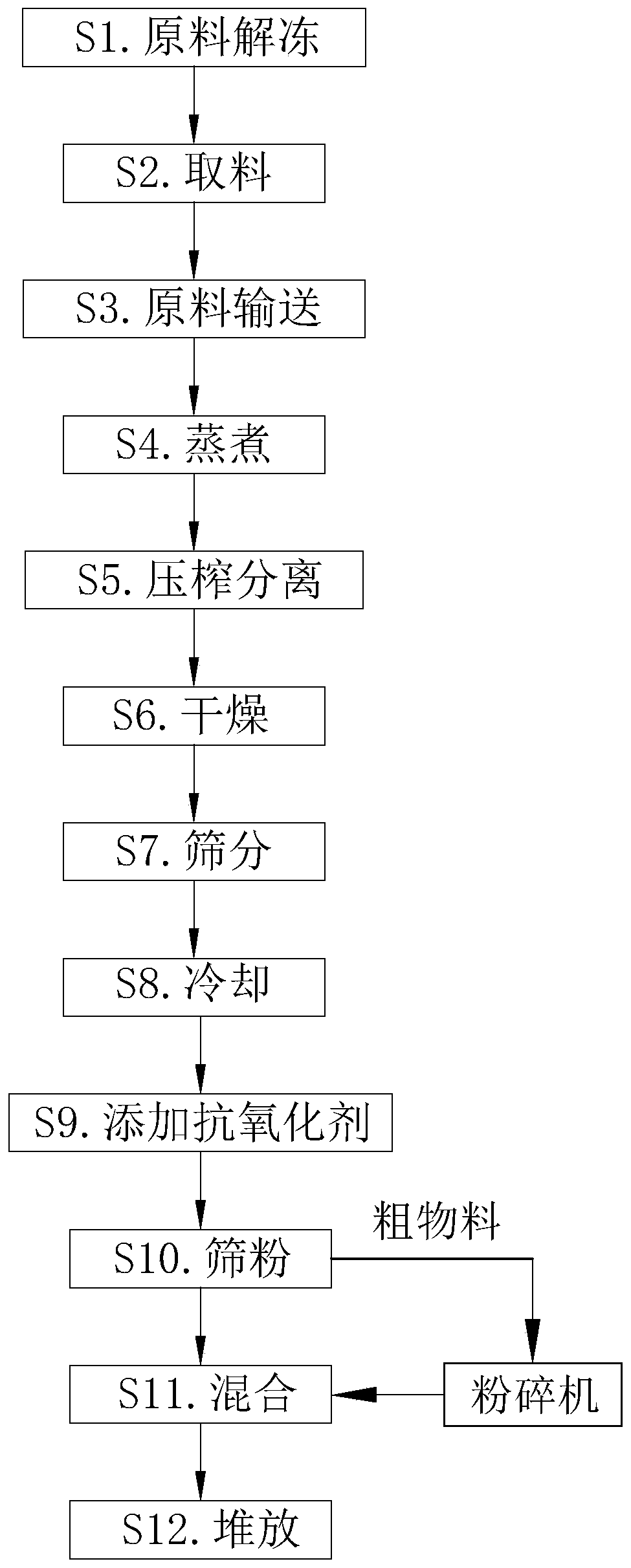

[0042] Embodiment 1, is a kind of fishmeal preparation process disclosed by the present invention, specifically comprises the following steps:

[0043] S1. Raw material thawing: Put the raw material into the raw material pool, and cool it naturally for 24 hours in the dark, and control the temperature of the center and surface of the raw material at 0°C;

[0044] S2. Material retrieving: use the grabber to grab the raw material from the raw material pool and evenly distribute it on the conveyor belt;

[0045] S3. Raw material transportation: Use a flat conveyor belt to transport raw materials to the cooking process. During the transportation process, the raw materials are preheated through the hot water in the water tank to raise the temperature of the raw materials to 40°C;

[0046] S4. Cooking: steaming the raw materials, heating the raw materials to 95°C;

[0047] S5. Pressing and separating: the fish oil and water in the raw materials are pressed and separated, and the wate...

Embodiment 2

[0057] Embodiment 2, is a kind of fishmeal preparation process disclosed by the present invention, and concrete procedure is the same as embodiment 1;

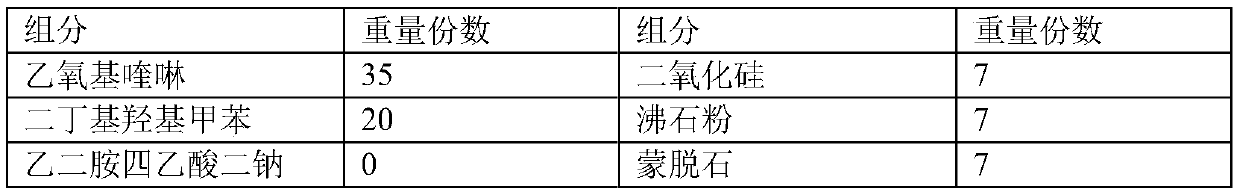

[0058] The antioxidant includes the following components in parts by weight.

[0059] components parts by weight components parts by weight Ethoxyquinoline 35 silica 15 Butylated hydroxytoluene 20 Zeolite powder 15 Disodium edetate 8 Montmorillonite 0 Butylated hydroxyanisole 12

Embodiment 3

[0060] Embodiment 3, is a kind of fishmeal preparation process disclosed by the present invention, and concrete procedure is the same as embodiment 1;

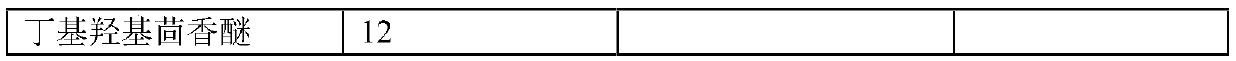

[0061] The antioxidant includes the following components in parts by weight.

[0062] components parts by weight components parts by weight Ethoxyquinoline 35 silica 30 Butylated hydroxytoluene 20 Zeolite powder 0 Disodium edetate 8 Montmorillonite 0 Butylated hydroxyanisole 12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com