Gluten formula with high elasticity and good toughness

A technology with good toughness and high elasticity, applied in food science and other directions, can solve the problems of affecting the post-processing and sales of gluten, poor gluten elasticity and toughness, and unfavorable eating experience, so as to ensure post-processing and sales, improve elasticity and toughness, The effect of enhancing the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

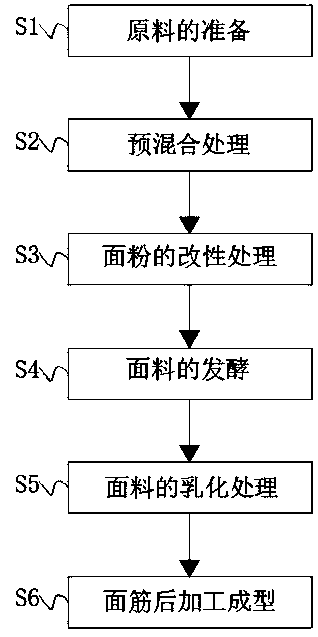

[0029] S1. Preparation of raw materials: First, take 25 parts of wheat flour, 35 parts of gluten powder, 2 parts of ash, 2 parts of enzyme preparation, 2 parts of dry yeast, 2 parts of improved oxidant, 2 parts of baking powder, 2 parts of emulsifier, 2 parts of table salt and the balance of water, and then each component is stored in a storage tank, the enzyme preparation is a combination of α-amylase and lipoxygenase, the improved oxidant is potassium bromate, emulsified The agent is a composition of calcium stearate lactate and sodium stearate lactate;

[0030] S2. Pre-mixing treatment: Pour the wheat flour and gluten powder measured in step S1 into the dough mixing equipment respectively, then add clear water of corresponding weight to the dough mixing equipment, then start the dough mixing equipment to work for 17 minutes, mix the wheat flour and gluten Prion powder is pre-mixed first;

[0031] S3. Flour modification treatment: Add the fluffy ash, enzyme preparation and ...

Embodiment 2

[0036] S1. Preparation of raw materials: First, take 20 parts of wheat flour, 30 parts of gluten powder, 3 parts of ash, 3 parts of enzyme preparation, 3 parts of dry yeast, 3 parts of improved oxidizing agent, 3 parts of baking powder, 3 parts of emulsifier, 3 parts of table salt and the balance of clear water, and then each component is stored in a storage tank respectively, the enzyme preparation is a composition of lipase and glucose oxidase, and the improved oxidant is azodicarbonamide, The emulsifier is a composition of monoglyceride tartrate and monoglyceride succinate;

[0037] S2, pre-mixing treatment: Pour the wheat flour and gluten powder measured in step S1 into the dough mixing equipment respectively, then add clear water of corresponding weights to the dough mixing equipment, then start the dough mixing equipment to work for 15 minutes, mix the wheat flour and gluten Prion powder is pre-mixed first;

[0038] S3. Flour modification treatment: Add the fluffy ash, ...

Embodiment 3

[0043] S1. Preparation of raw materials: First, take 30 parts of wheat flour, 40 parts of gluten powder, 1 part of ash, 1 part of enzyme preparation, 1 part of dry yeast, 1 part of improved oxidant, 1 part of baking powder, 1 part of emulsifier, 1 part of table salt and the balance of water, and then each component is stored in a storage tank, the enzyme preparation is a combination of lipoxygenase and lipase, the improved oxidant is calcium iodate, emulsified The agent is a composition of sucrose fatty acid ester and soybean lecithin;

[0044] S2. Pre-mixing treatment: Pour the wheat flour and gluten powder measured in step S1 into the dough mixing equipment respectively, then add clear water of corresponding weight to the dough mixing equipment, then start the dough mixing equipment to work for 20 minutes, mix the wheat flour and gluten Prion powder is pre-mixed first;

[0045] S3. Flour modification treatment: Add the fluffy ash, enzyme preparation and improved oxidant mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com