High polymer material, super-hydrophobic porous membrane, coating, preparation method and applications

A polymer material and super-hydrophobic technology, which is applied in the fields of polymer materials and their preparation, coating, and super-hydrophobic porous membrane, can solve the complicated process, the surface does not have a micro-nano rough structure, and the process of increasing the super-hydrophobic fiber membrane is complicated. degree and other issues, to achieve the effect of avoiding secondary pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The embodiment of the present invention also provides a kind of polymer material, and its preparation method comprises:

[0052] Dissolving the hydrophobic polymer in a high surface tension solvent to form a polymer solution with a concentration of 0.05-1.0 g / mL;

[0053] Electrospinning is performed on the polymer solution to obtain the polymer material, wherein the electrospinning temperature is 5-80° C., the time is 2-48 hours, and the relative humidity is 40-100%. The wire voltage difference is 8-40kV, the rotational speed of the receiving end is 5-100r / min, the injection speed of the polymer solution is 0.01-5mL / h, and the distance between the needle and the receiver is 5-40cm.

[0054] Further, the polymer material is prepared by high-humidity-induced electrospinning technology, without any pre-treatment or post-treatment process, the prepared polymer material has super-hydrophobic properties, and its water contact angle can reach 150 °~170°.

[0055] In some em...

Embodiment 1

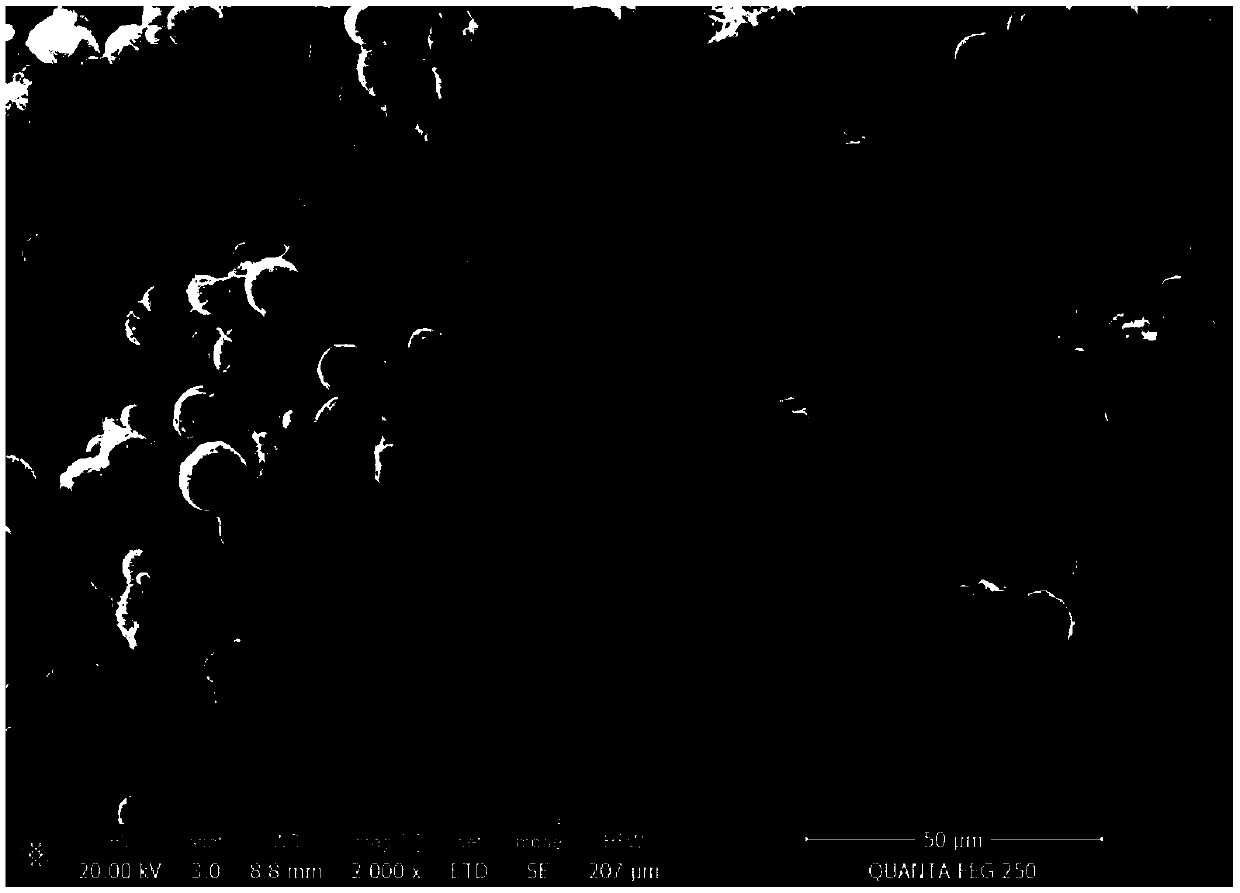

[0093] Weigh powdered polyvinylidene fluoride, dissolve it in N-methylpyrrolidone at a concentration of 0.18 g / mL, stir at 80°C for 15 hours, and let stand for defoaming for 6 hours to prepare a polymer membrane solution. The above solution was spun onto an aluminum foil substrate by electrospinning, the temperature during spinning was 25°C, the relative humidity of water vapor was 75%, the pushing speed was 1.3mL / h, the receiving speed was 20r / min, and the voltage difference was 12kV , the distance between the needle and the receiver was 11cm, and the electrospinning treatment time was 12h. After spinning, the membrane was dried at 25° C. for 24 hours to obtain an electrospun superhydrophobic porous membrane. The optical picture and hydrophobicity of the superhydrophobic porous membrane refer to Figure 2a as well as Figure 2b . It can be seen from the optical pictures that the size of the two films is 15×15cm 2 Above, the water drop on it is a ball, and can roll freely....

Embodiment 2

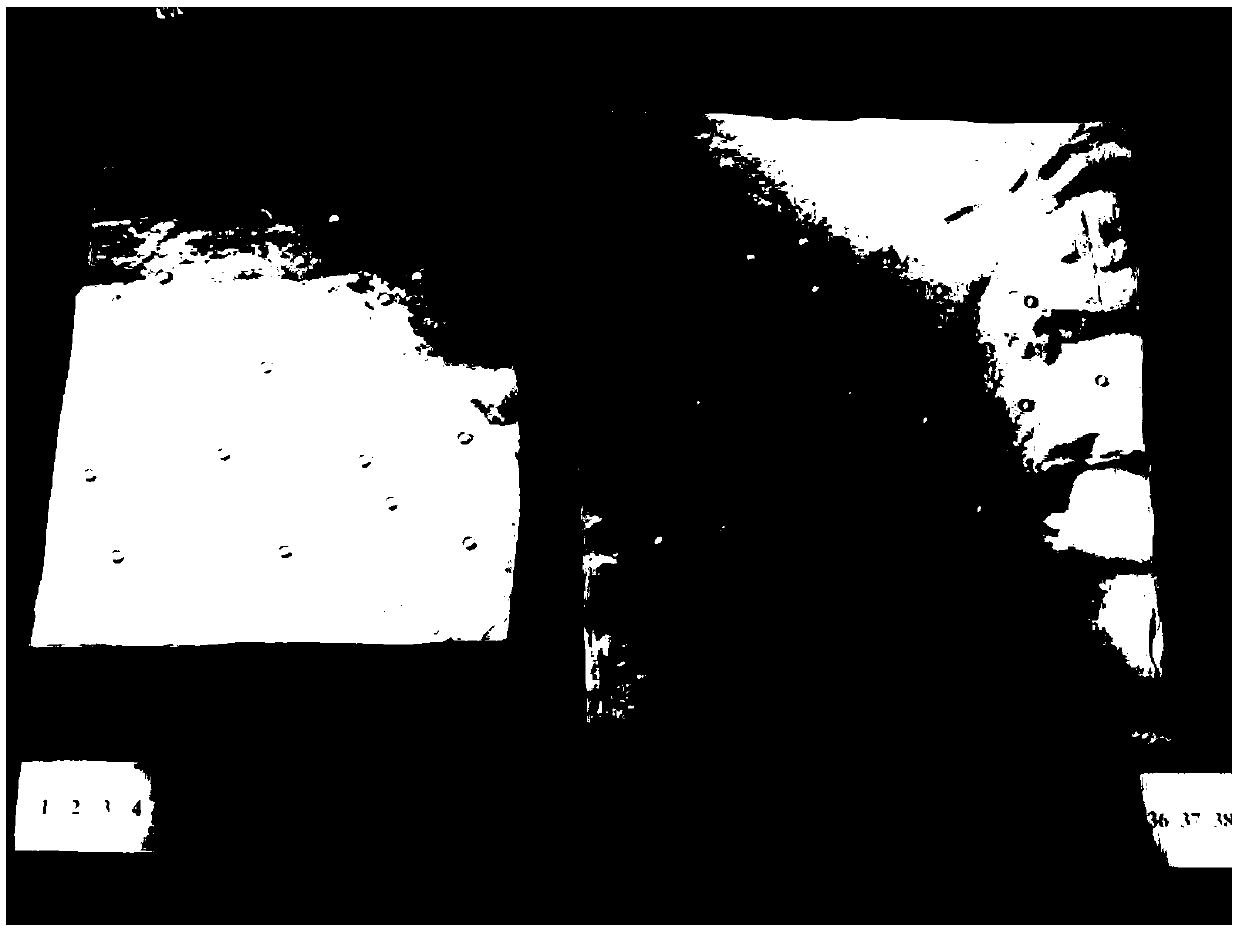

[0095] Weigh powdered polyvinylidene fluoride, dissolve them in N-methylpyrrolidone with solutions of 0.15, 0.175, 0.20, 0.225, and 0.25 g / mL respectively, stir at 60°C for 12 hours, let stand for 8 hours to defoam, and prepare polymer membrane solution. The above solution was spun onto an aluminum foil substrate by electrospinning, the temperature during spinning was 25°C, the relative humidity of water vapor was 75%, the pushing speed was 1.5mL / h, the rotational speed of the receiving end was 25r / min, and the voltage difference was 15kV, the distance between the needle and the receiver is 14cm, and the electrospinning time is 8h. After spinning, the membrane was dried at 25° C. for 24 hours to obtain an electrospun superhydrophobic porous membrane. Carry out pore size analysis to the membrane obtained, its test result can refer to Figure 4 . Curves 1, 2, 3, 4, and 5 are the pore size distribution curves obtained from membrane tests obtained from solutions with concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com