Method of preparing graphene by using supercritical CO2 assisted liquid phase stripping

A technology of CO2 and auxiliary liquid, which is applied in the production of graphene, bulk chemicals, nano-carbon, etc., can solve the problems of poor quality and low production efficiency of graphene, and achieve good structural integrity, green production process, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weighing 60 mg of natural graphite powder and 60 mL of NMP to form a reaction solution with a concentration of 1 mg / mL, and ultrasonically mixing in a water bath for 10 minutes;

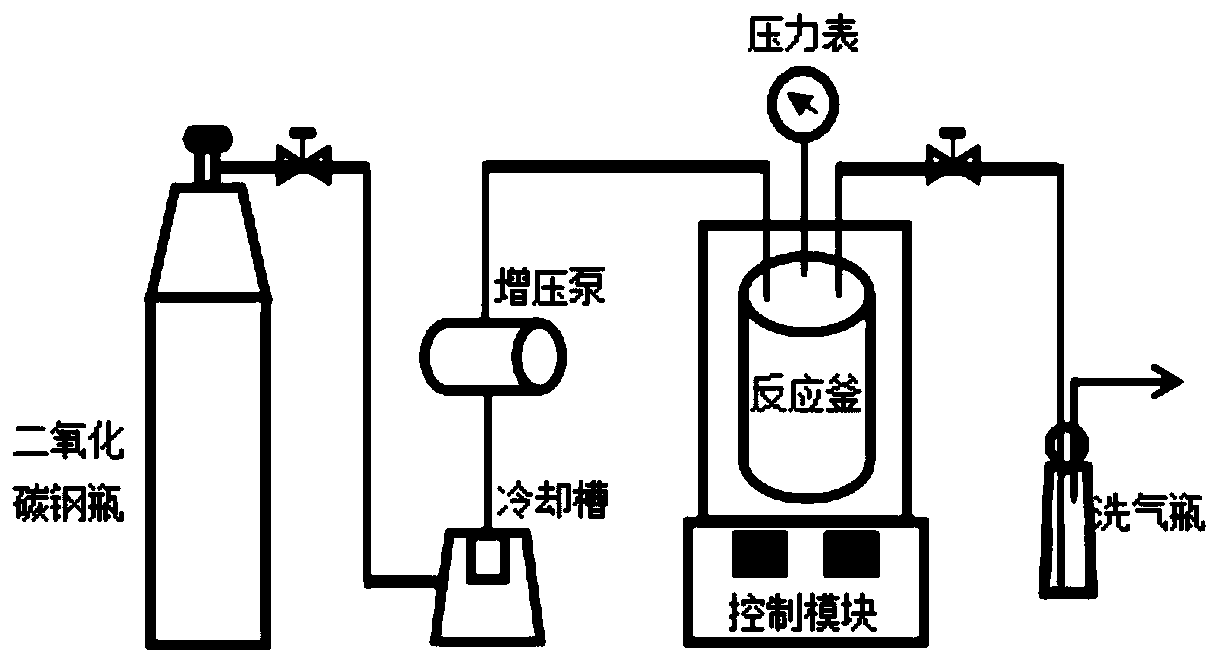

[0025] (2) Add the solution to figure 1 In the reaction kettle shown, after heating the reaction kettle to 40°C through the control module, turn on the mechanical stirring (1000rpm) and use the booster pump to pump the CO in the carbon dioxide bottle 2 Pump it into the reaction kettle, and the reaction will start after the pressure reaches 12MPa;

[0026] (3) After reacting for 2 hours, take out the reactor and place it in a water bath to cool to below 25°C, open the exhaust valve to let the CO 2 go through figure 1 After washing the bottle shown, pour the solution into the beaker;

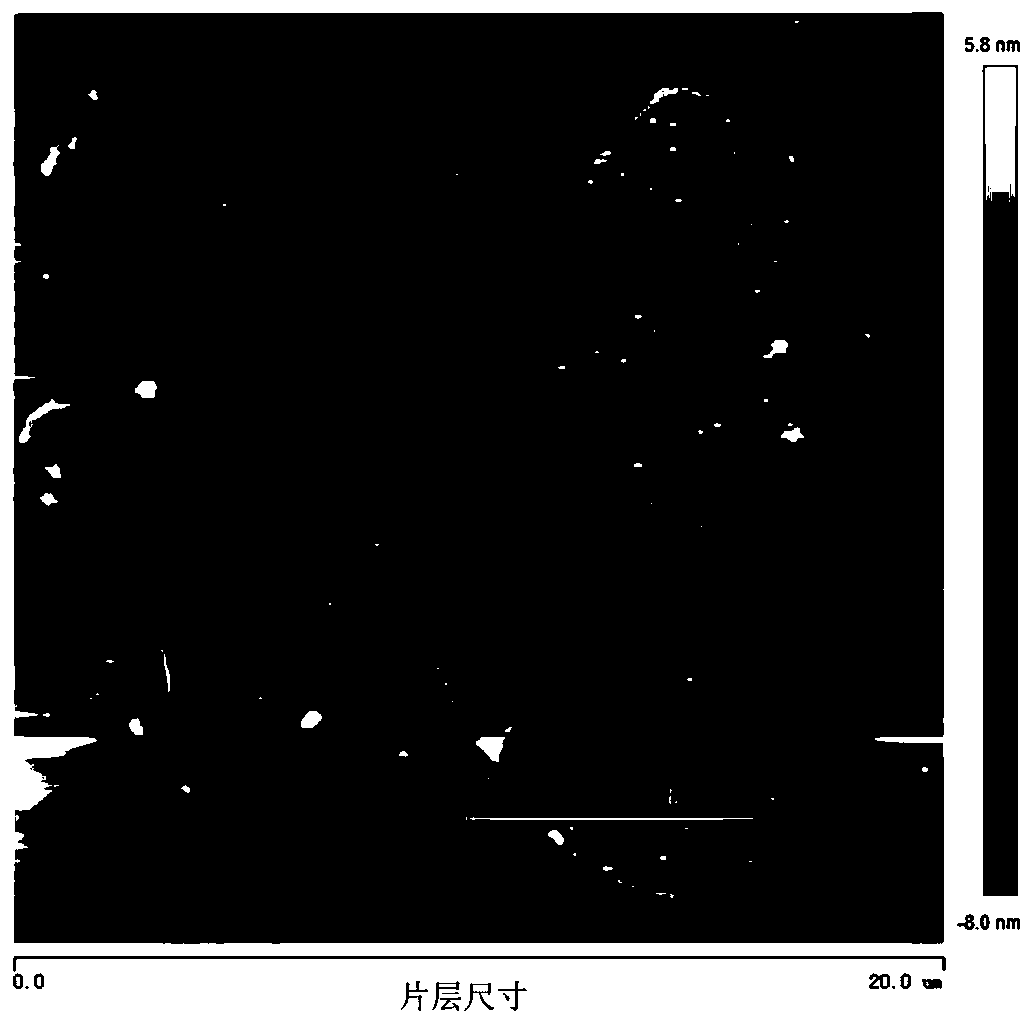

[0027] (4) Ultrasonic disperse the taken-out solution for 45 minutes, pour it into a centrifuge tube and centrifuge at 2500rpm for 30 minutes, and then take the supernatant to obtain a graphene solution wit...

Embodiment 2

[0029] (1) Weigh 210mg of expandable graphite powder and 70mL of NMP to form a reaction solution with a concentration of 3mg / mL, and ultrasonically mix in a water bath for 5 minutes;

[0030] (2) Add the solution to figure 1 In the reaction kettle shown, after heating the reaction kettle to 50°C through the control module, turn on the magnetic stirring (1500rpm) and use the booster pump to remove the CO in the carbon dioxide bottle. 2 Pump it into the reaction kettle, and the reaction will start after the pressure reaches 16MPa;

[0031] (3) After reacting for 4 hours, take out the reaction kettle and place it in a water bath to cool to below 25°C, open the exhaust valve to drain the CO 2 go through figure 1 The indicated scrubber bottle is drained, and the solution is poured into a beaker;

[0032] (4) Ultrasonic disperse the taken-out solution for 45 minutes, pour it into a centrifuge tube and centrifuge at 2500 rpm for 30 minutes, and then take the supernatant to obtain ...

Embodiment 3

[0034] (1) Weigh 300mg of expandable graphite powder and 60mL of DMF to form a reaction solution with a concentration of 5mg / mL, and ultrasonically mix in a water bath for 15 minutes;

[0035] (2) Add the solution to a preheated to 80°C figure 1 In the reactor, open mechanical stirring (2000rpm) and utilize figure 1 The booster pump in the reactor feeds CO into the reactor 2 , the reaction starts after the pressure reaches 20MPa;

[0036] (3) After reacting for 6 hours, take out the reactor and place it in a water bath to cool to below 25°C, open the exhaust valve to drain the CO 2 go through figure 1 The washing bottle is discharged, and the solution is poured into the beaker;

[0037] (4) Ultrasonic disperse the taken-out solution for 60 minutes, pour it into a centrifuge tube and centrifuge at 2500 rpm for 30 minutes, and then take the supernatant to obtain a graphene solution with a concentration of 0.46 mg / mL. Graphene sheets with less than ten layers accounted for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com