Composition for wet etching to silicon nitride

一种组合物、化合物的技术,应用在表面浸蚀组合物、化学仪器和方法、电气元件等方向,能够解决增加硅浓度等问题,达到氮化硅膜去除的问题改善、广泛应用、高蚀刻选择性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

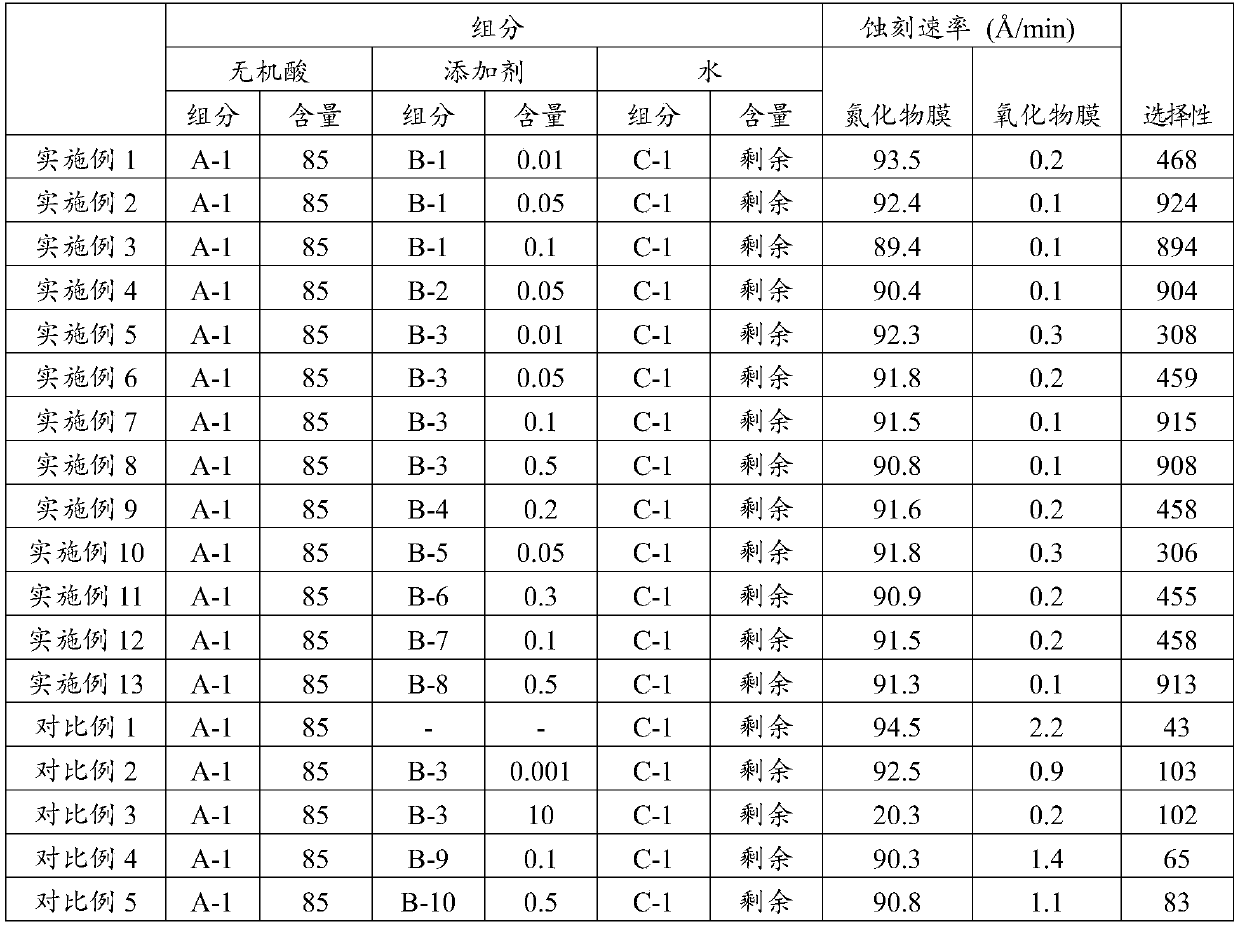

[0031] Embodiments of the present invention relate to an etchant composition that includes phosphoric acid, a silicon-based compound, and water, but does not contain fluorine. The etchant composition is capable of selectively etching a silicon nitride film while suppressing damage to an underlying metal film and the like and etching of a silicon oxide film.

[0032] More specifically, this embodiment relates to a selective silicon nitride film etchant composition capable of selectively wet etching silicon nitride during the fabrication of semiconductors, dynamic random access memory (DRAM) and NAND flash memory A film wherein the composition has at least 200 times higher etch selectivity.

[0033] Hereinafter, specific embodiments of the present invention will be described. However, this is just an example, but the present invention is not limited thereto.

[0034] The inorganic acid is any one selected from sulfuric acid, nitric acid, phosphoric acid and mixtures thereof. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com