Design of cancellous bone bionic scaffold prepared by 3d printing technology and application thereof

A 3D printing and bionic technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as non-union, application limitations, and easy infection, and achieve the effect of eliminating variable differences and reliable scaffold models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Design and preparation of cancellous bone bionic scaffold

[0031] 1.1 Three-dimensional modeling of cancellous bone biomimetic scaffold

[0032]Rhinoceros is a commonly used parametric 3D model design software. In this study, through the Rhinoceros 5 software (v.5.1.30103.145) and the Grasshopper plug-in (v.August-27, 2014) algorithm function design loose Bone biomimetic model.

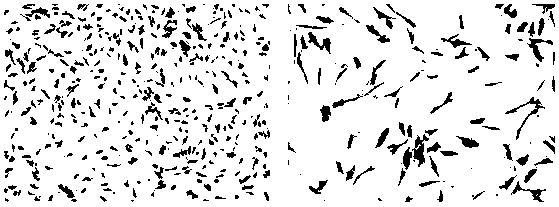

[0033] The bionic bracket designed in this study mainly uses the three-dimensional Voronoi algorithm. The Voronoi diagram is also called the Thiessen polygon. In a single plane, a vertical line is drawn at the midpoint of the line connecting two adjacent points. These vertical lines divide each point. into an independent region. If the Voronoi algorithm is applied to a three-dimensional space, a vertical plane is made at the midpoint of the line connecting two adjacent points, and these vertical planes enclose each point into an independent space. The Voronoi algorithm is used to ...

Embodiment 2

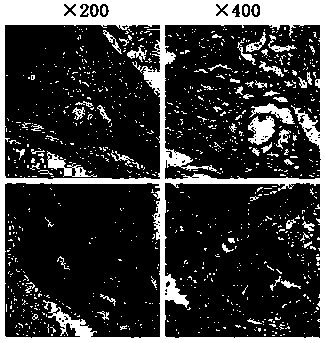

[0069] Example 2 Calcination of natural bovine cancellous bone by ammonium dihydrogen phosphate method and detection of scaffold structure

[0070]2.1 Calcination of bovine cancellous bone by ammonium dihydrogen phosphate method

[0071] 2.1.1 Bone preparation and pretreatment

[0072] Fresh adult femurs were purchased from the local market. Use a hacksaw to cut off the femoral neck and medial and lateral condyles from both ends of the femur. Soak them in 0.5M / L sodium hydroxide for 3 hours at room temperature and pressure, boil them for 30 minutes, and cut them with a hacksaw. Saw several cancellous bone pieces with a size of 10×10×10 mm, soak them in 0.5M / L sodium hydroxide for 24 hours, and dry them.

[0073] 2.1.2 Calcined bone by ammonium dihydrogen phosphate method

[0074] Place the bone in a muffle furnace, slowly raise the temperature (6°C / min) to 900°C, keep it for 4 hours, and take it out after cooling. Soak in 0.5M ammonium dihydrogen phosphate for 24 hours, dry...

Embodiment 3

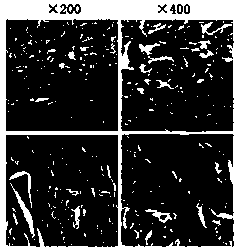

[0100] Example 3 In Vitro Biological Evaluation

[0101] 3.1 Extraction and culture of rat bone marrow mesenchymal stem cells

[0102] One 4-week-old male SD rat was selected and sacrificed by cervical dislocation, soaked in 0.5% iodophor for 3 minutes for disinfection, and then separated the bilateral femur and tibia under aseptic conditions, washed out the bone marrow with low-sugar DMEM culture medium, and obtained cell suspension Centrifuge at 2000r / min for 10min. Then resuspend with 15mL DMEM medium containing 10% fetal bovine serum and 1% double antibody, and add 1×10 8 L -1 Density seeded at 25cm 2 Place in a culture bottle and culture in a 37°C, CO2 constant temperature incubator. 24 hours after inoculation, half of the medium was changed for the first time to remove unattached cells. Afterwards, the medium was changed every 3 days. When the adherent cells grew and reached more than 90% confluence, they were digested and subcultured with 0.25% trypsin, and subcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com