Device for high-depth-diameter-ratio micro-hole high-speed electrosparking

A depth-to-diameter ratio and electric spark technology, applied in the field of machining and tools, can solve the problems of fast wear of the rotating spindle, electrochemical corrosion of the spindle, and small impact force of the abrasive jet, so as to reduce the wear rate, improve stability, and improve The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

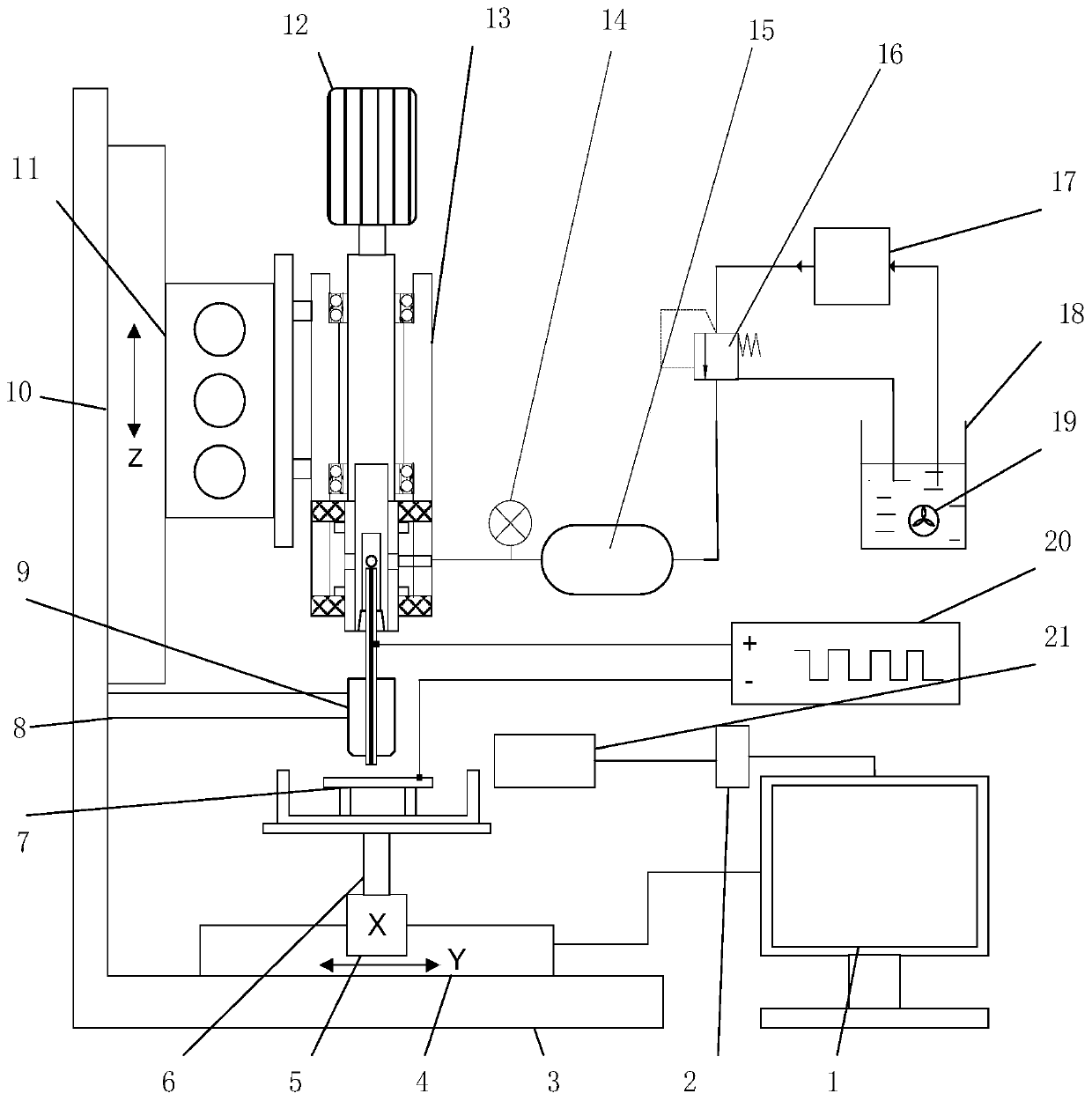

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

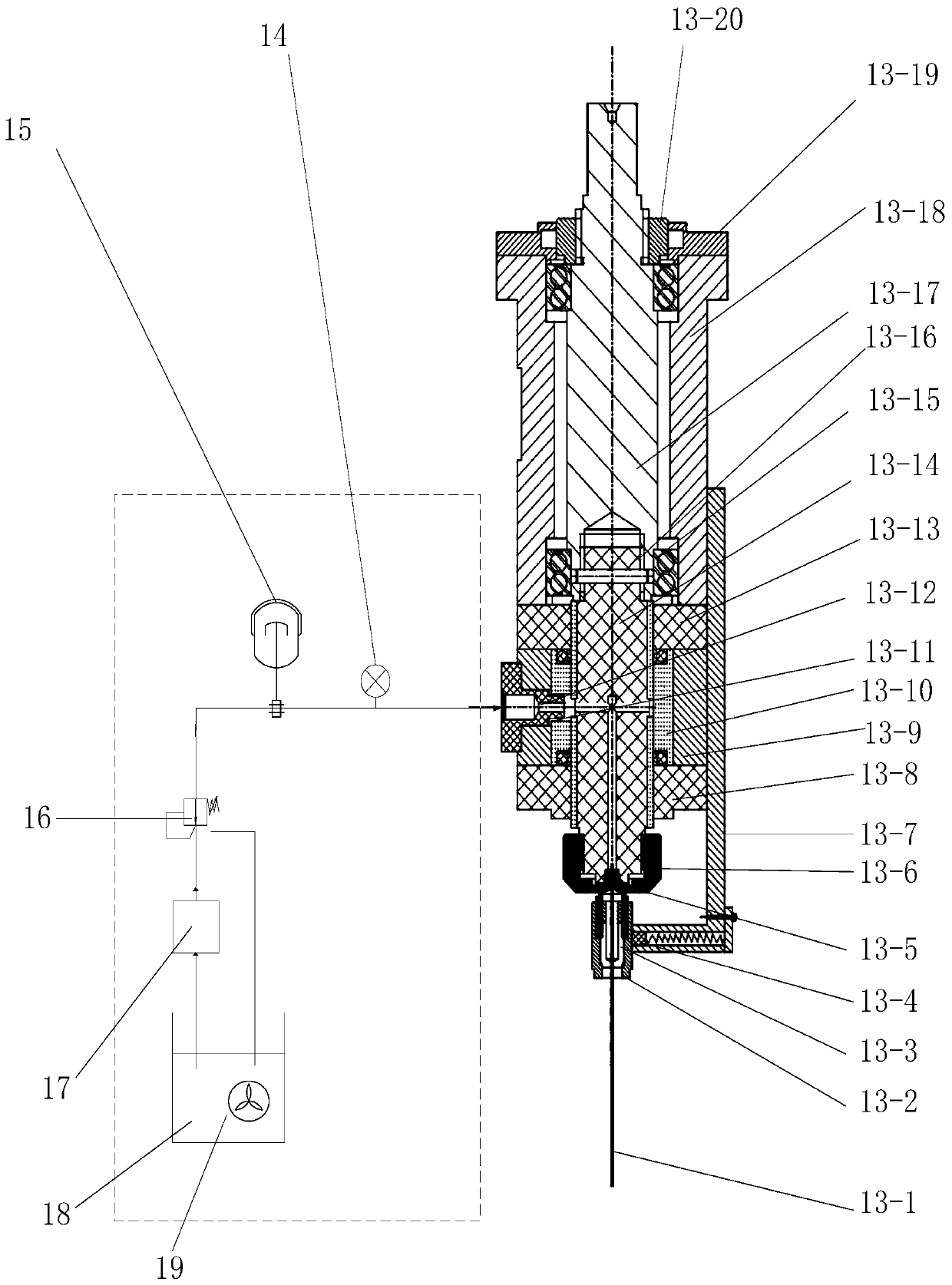

[0017]The invention relates to a high-speed electric spark microhole processing device with a large depth-to-diameter ratio. The equipment used is an XYZ three-axis machine tool, a rotating spindle and a working fluid pipeline. EDM machine tool includes: upper computer 1, A / D converter 2, marble base 3, Y movement spindle 4, X movement spindle 5, liftable support table 6, workpiece clamping platform 7, guide support frame 8, guide Device 9, Z motion spindle 10, spindle support frame 11, pulse power supply 20, discharge state detector 21.

[0018] The rotating spindle includes: servo motor 12, tube electrode 13-1, conductive nut 13-2, electrode chuck 13-3, power supply carbon brush 13-4, electrode sealing water stopper 13-5, locking nut 13- 6. Carbon brush holder 13-7, adjustable lower cover plate 13-8, gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com