A kind of structurally stable composite structure chromogenic material and its preparation method

A composite structure and structurally stable technology, applied in chemical instruments and methods, synthetic resin layered products, devices for coating liquids on surfaces, etc. problems, to achieve the effect of overcoming poor structural stability, easy operation and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

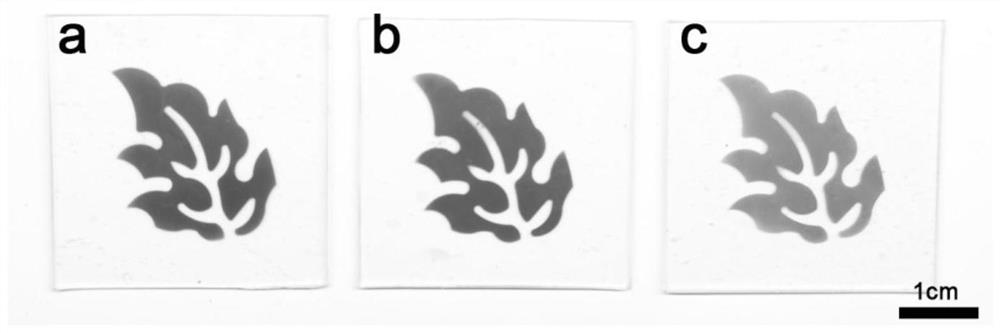

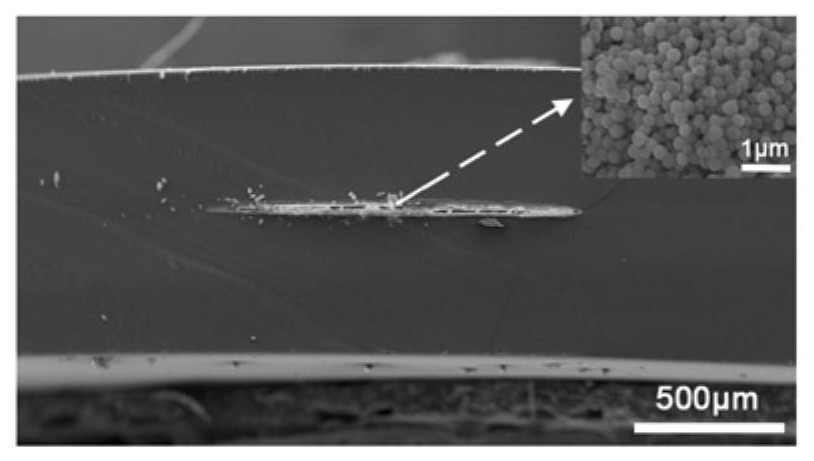

[0042] 1. Under the cover of the hollow mold by spraying method, spray bisphenol-formaldehyde resin microsphere emulsion with a diameter of 283nm, 239nm and 197nm with a solid content of 10%, and assemble disorderly on the PVC film to prepare three colors of amorphous photons The pattern of the structure.

[0043] 2. The hot pressing equipment is preheated to 120°C, and the PVC film coated with the amorphous photonic structure pattern is covered with another layer of PVC film, and the two layers of PVC film are bonded and bonded into a whole by hot pressing, with a pressure of 8kN , to obtain a stable composite structure chromogenic material.

Embodiment 2

[0045] 1. The bisphenol-formaldehyde resin microsphere emulsion with a diameter of 283, 239 and 197nm with a solid content of 10% is compounded with an aqueous solution of carbon black with a solid content of 0.01g / ml at a mass ratio of 20:1 to obtain a mixed emulsion, Under the cover of the hollow mold by spraying method, three kinds of bisphenol-formaldehyde resin microsphere mixed emulsions were sprayed respectively to assemble disorderly on the TPU film to prepare the pattern of the amorphous photonic structure.

[0046] 3. The hot pressing equipment is preheated to 120°C, and the TPU film coated with the amorphous photonic structure pattern is covered with the TPU mobile phone case, and the two layers of the TPU film are bonded and bonded into a whole by hot pressing, and the pressure is 8kN, and the obtained Structurally stable composite structural chromogenic material mobile phone case.

Embodiment 3

[0048] 1. By the heating assembly method, a PVC film is placed on a heating plate at a temperature of 60° C., and a bisphenol-formaldehyde resin microsphere emulsion with a diameter of 10% and a diameter of 283 nm is ordered on the PVC film to prepare photonic crystals.

[0049] 2. Preheat the hot-pressing equipment to 120°C, cover the PVC film coated with the photonic crystal layer with another layer of PVC film, and make the two layers of PVC film bonded and bonded into a whole by hot pressing at a pressure of 8kN. Composite structural chromogenic material with stable structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com