Synthesis of high crystallinity ets-10 zeolite molecular sieve with tunable morphology and pore structure

A technology of zeolite molecular sieve and synthesis method, which is applied in the directions of crystalline aluminosilicate zeolite, molecular sieve and alkali exchange compound, molecular sieve catalyst, etc., can solve the problems of destroying structural integrity, reducing crystallinity of zeolite molecular sieve, etc., and improving the conversion rate of raw materials , Guaranteed yield, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

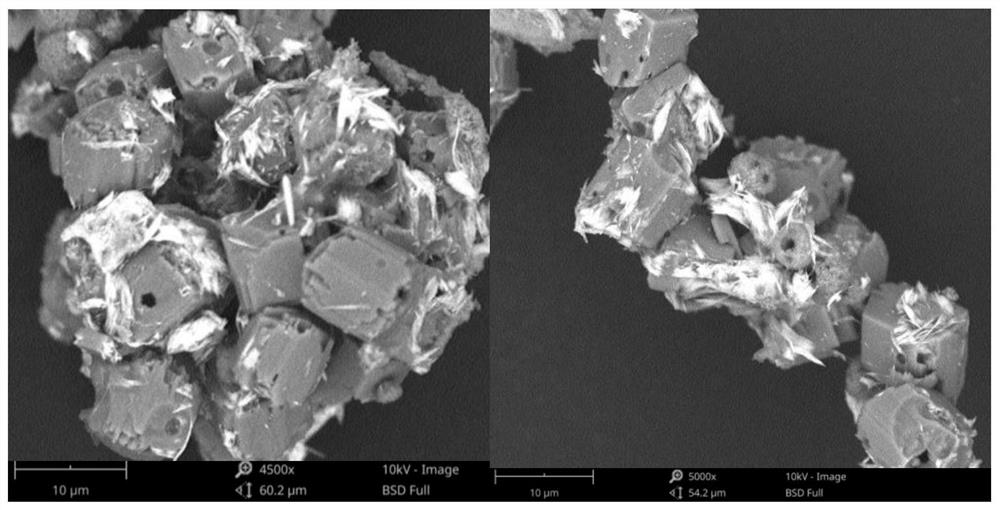

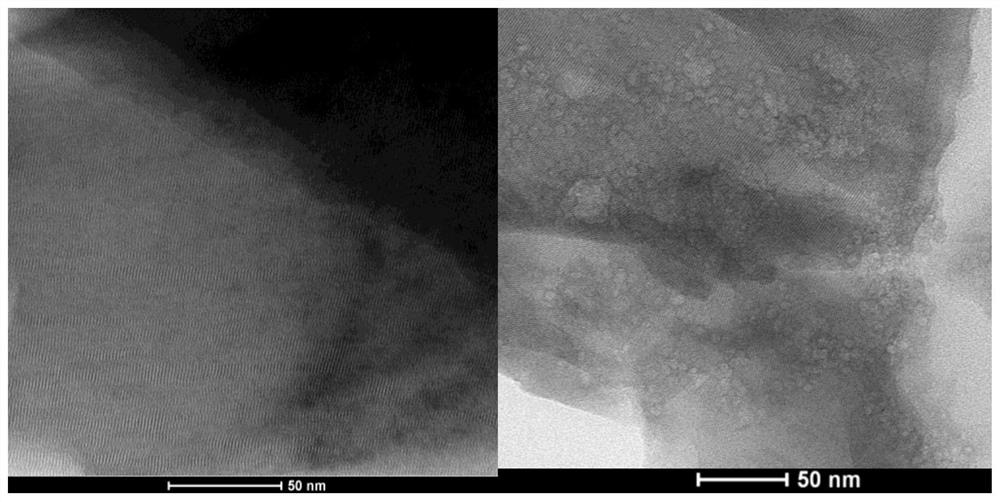

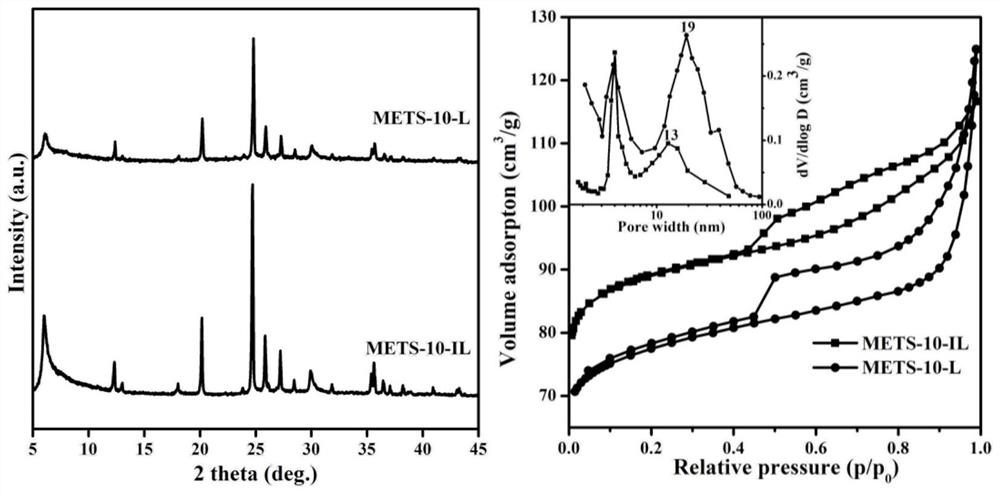

experiment example 1

[0043] Take 16mL of water glass and stir it at room temperature for 10min, then fully mix it with 2mL of IL-LnNa solution, stir for 1h, then add 20mL of H 2 O and continue to stir for 20min, then add 6.9g NaCl and 2.8g KF successively and stir for 1h respectively, finally add 1.3g P25, stir for 2h, put it into a hydrothermal reaction kettle and seal it, and put it in an oven at 230°C for 60 hours to crystallize . The molar ratio of each material in the system Na 2 O:K 2 O:TiO 2 : SiO 2 :IL-LnNa:H 2 O is recorded as 3.5:1.6:1.0:5.5:0.043:181. The texture properties of the obtained hierarchically porous ETS-10 zeolite are shown in Table 1.

experiment example 2

[0045] Take 16mL water glass and stir at room temperature for 10min, then add 20mL H 2 O Stir evenly, then add 2mL IL-LnNa solution after 20min and mix well, after stirring for 1h, add 6.9g NaCl and 2.8g KF in turn, after each stirring for 1h, add 1.3g P25, continue stirring for 2h, put it into a hydrothermal reaction kettle and seal , placed in an oven at 230°C for 60 hours for crystallization. The molar ratio of each material in the system Na 2 O:K 2 O:TiO 2 : SiO 2 :IL-LnNa:H 2 O is recorded as 3.5:1.6:1.0:5.5:0.043:181. The texture properties of the obtained hierarchically porous ETS-10 zeolite are shown in Table 1.

experiment example 3

[0047] Take 16mL water glass and stir at room temperature for 10min, then add 20mL H 2 O and stir evenly, after 20min, add 6.9gNaCl and 2.8g KF successively, stir for 1h each, then add 2mL IL-LnNa solution and mix well, after stirring for 2h, add 1.3gP25, continue stirring for 2h, put it into a hydrothermal reaction kettle and seal it, Stand in an oven at 230°C for 60 hours for crystallization. The molar ratio of each material in the system Na 2 O:K 2 O:TiO 2 : SiO 2 :IL-LnNa:H 2 O is recorded as 3.5:1.6:1.0:5.5:0.043:181. The texture properties of the obtained hierarchically porous ETS-10 zeolite are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com