Chromium-containing wastewater online circulation treatment device and method

A technology for recycling and chromium wastewater, applied in the field of water treatment, can solve the problems of high sludge disposal costs, high treatment costs, large sludge output, etc., and achieve the effects of programming control, high degree of automation, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

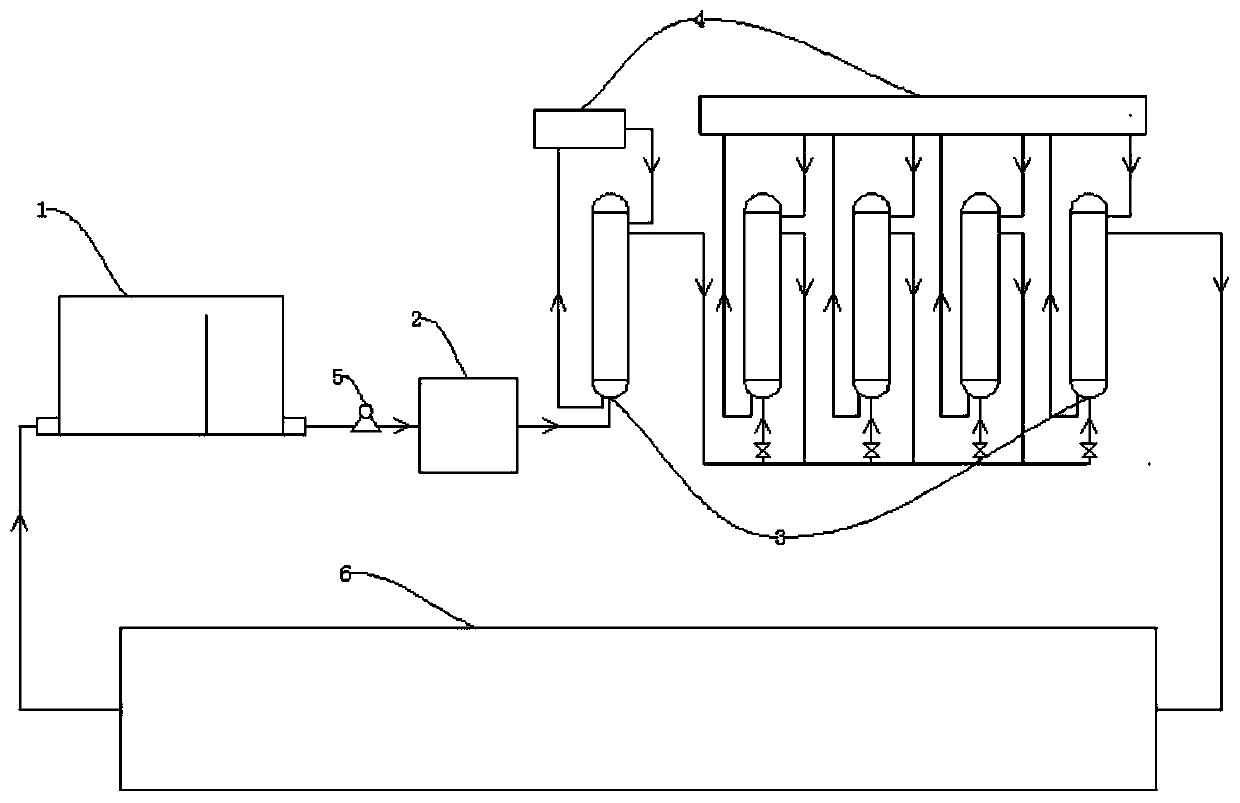

[0040] Such as figure 1 As shown, the present invention provides a process flow diagram of an online circulation treatment device for chromium-containing wastewater. The wastewater is lifted to a slag removal device 1 with a special structure through a water pump. The slag removal device 1 includes an inclined tube sedimentation tank and a clear water tank. The inclined tube sedimentation tank intercepts and settles the impurities and suspended particles in the wastewater to reduce the load of subsequent treatment units. Both the bottom of the inclined tube sedimentation tank and the clear water tank are provided with a funnel-shaped mud hopper; the outside of the equipment is provided with a UPVC mud discharge valve at a corresponding height. The waste water entering the slag removal device 1 flows into the inclined tube sedimentation zone from bottom to top through the gap arranged at the bottom of the clapboard of the inclined tube sedimentation tank. Impurities and flocs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com