PVC environment-friendly calcium-zinc composite stabilizer and preparation method thereof

A calcium-zinc composite and stabilizer technology, applied in the field of PVC stabilizers, can solve the problems of lead salt stabilizers being opaque, lead-intensive ecological pollution, and harm to people's lives, and achieve easy industrial promotion and application, low price, and simple preparation methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

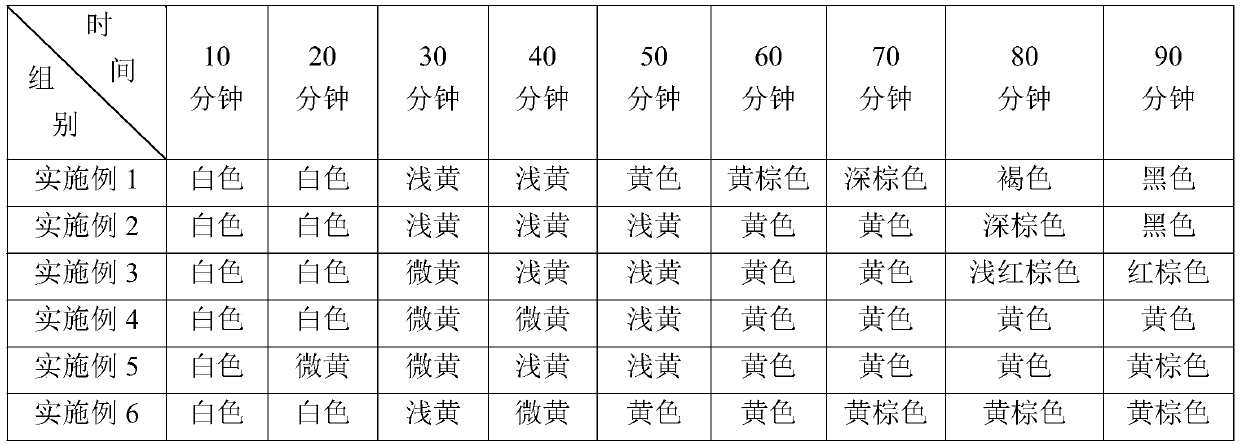

Examples

Embodiment 1

[0019] A PVC environment-friendly calcium-zinc composite stabilizer, comprising the following components in parts by weight: 40 parts of allantoin calcium-zinc compound, 25 parts of calcium lanolate, 10 parts of non-toxic phosphite, 8 parts of dipentaerythritol, three 13 parts of hydroxymethylaminomethane, 16 parts of magnesium aluminum hydrotalcite, 9 parts of β-diketone, 10105 parts of antioxidant, 12 parts of acrylic acid amide and 6 parts of monoglyceride.

[0020] The preparation method of the allantoin calcium-zinc compound is as follows: 1. Dissolving allantoin in hot water; 2. Adding zinc sulfate heptahydrate to the allantoin solution, after the solution is clarified, stirring and reacting at 85°C for 1 hour; 3. Cool the reacted solution to 40°C, add calcium chloride under stirring, keep warm for 1.5h, cool, remove water, and dry to obtain the allantoin calcium-zinc compound.

[0021] The preparation method of the calcium lanolate is as follows: 1. Melting the crude wo...

Embodiment 2

[0024] A PVC environment-friendly calcium-zinc composite stabilizer, comprising the following components in parts by weight: 40 parts of allantoin calcium-zinc compound, 25 parts of calcium lanolate, 10 parts of diisodecyl phosphite, tris(2-hydroxy 8 parts of ethyl) isocyanurate, 13 parts of ethyl-3-aminobutyrylate, 16 parts of magnesium aluminum hydrotalcite, 9 parts of β-diketone, 10765 parts of antioxidant, 12 parts of acrylic acid amide and mono Glycerin 6 parts.

[0025] The preparation method of the allantoin calcium-zinc compound is as follows: 1. Dissolving allantoin in hot water; 2. Adding zinc sulfate heptahydrate to the allantoin solution, after the solution is clarified, stirring and reacting at 80°C for 1.5h; 3. 1. Cool the reacted solution to 45° C., add calcium oxide under stirring, keep warm and continue the reaction for 1 hour, cool, remove water, and dry to obtain the allantoin calcium-zinc compound.

[0026] The preparation method of the calcium lanolate is...

Embodiment 3

[0029] A PVC environment-friendly calcium-zinc composite stabilizer, comprising the following components in parts by weight: 40 parts of allantoin calcium-zinc compound, 25 parts of calcium lanolate, 10 parts of diisodecyl phosphite, 8 parts of dipentaerythritol, 13 parts of Tris, 16 parts of magnesium aluminum hydrotalcite, 9 parts of β-diketone, 10105 parts of antioxidant, 12 parts of acrylic acid amide and 6 parts of monoglyceride.

[0030] The preparation method of the allantoin calcium-zinc compound is as follows: 1. Dissolving allantoin in hot water; 2. Adding zinc sulfate heptahydrate to the allantoin solution, after the solution is clarified, stirring and reacting at 85°C for 1 hour; 3. Cool the reacted solution to 45°C, add the calcium-containing compound while stirring, keep the temperature and continue the reaction for 1.5h, cool, remove water, and dry to obtain the allantoin calcium-zinc compound.

[0031] The preparation method of the calcium lanolate is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com