Aqueous graphene conductive coating material and preparation method therefor

A technology of water-based graphene and conductive coatings, applied in the direction of conductive coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of unsuitability for large-scale production, agglomeration and entanglement, and large amount of carbon black added, and achieve effective Conducive to large-scale promotion and application, improved dispersion performance, mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

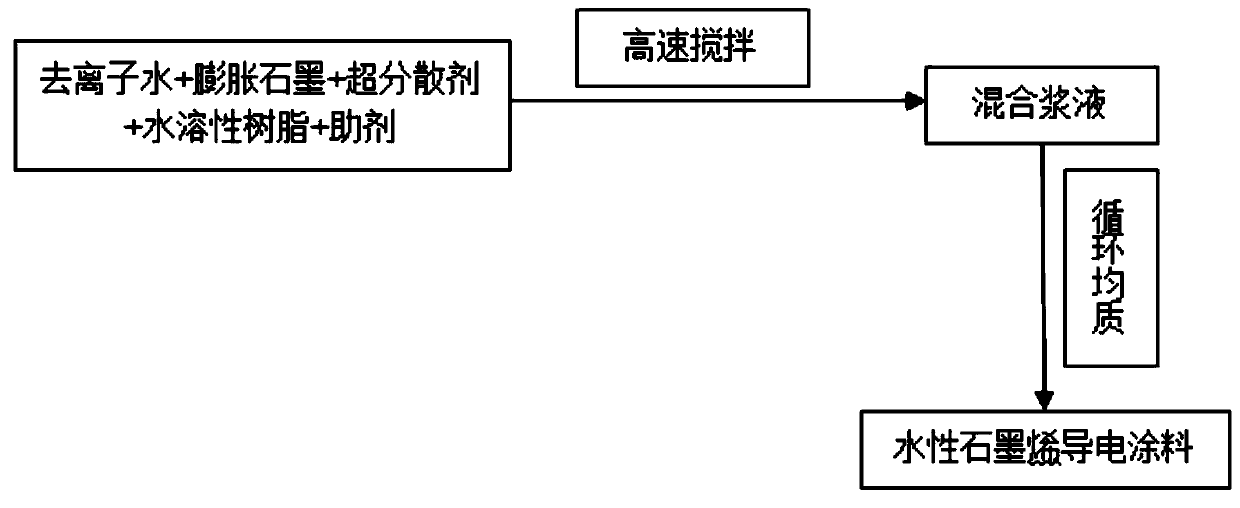

[0074] The present invention also provides a kind of preparation method of the water-based graphene conductive coating as described in any one of the above-mentioned technical schemes, comprises the following steps:

[0075] 1) After mixing expanded graphite, water-soluble resin emulsion, supramolecular dispersant, water and other additives, a mixture is obtained;

[0076] 2) After the mixture obtained in the above steps is homogenized, the water-based graphene conductive coating is obtained.

[0077] The present invention is to the selection and composition of the raw material in the preparation method of described water-based graphene conductive paint, and corresponding optimal principle, and the selection and composition of corresponding raw material in the aforementioned water-based graphene conductive paint, and corresponding optimal principle all can be Correspondingly, details are not repeated here.

[0078] The invention firstly mixes expanded graphite, water-soluble ...

Embodiment 1

[0094] Weigh 10 parts of deionized water, 1.0 part of expanded graphite, 1.0 part of supramolecular dispersant, 60 parts of water-based acrylic resin, 0.05 part of defoamer, 0.05 part of leveling agent, 0.1 part of wetting agent, anti-flash rust additive 0.1 part, 0.3 part of film-forming aid, mix the materials evenly in the high-speed mixer, the speed is 600r / min, and the time is 15min. 4 times, the water-based graphene conductive coating can be obtained by discharging.

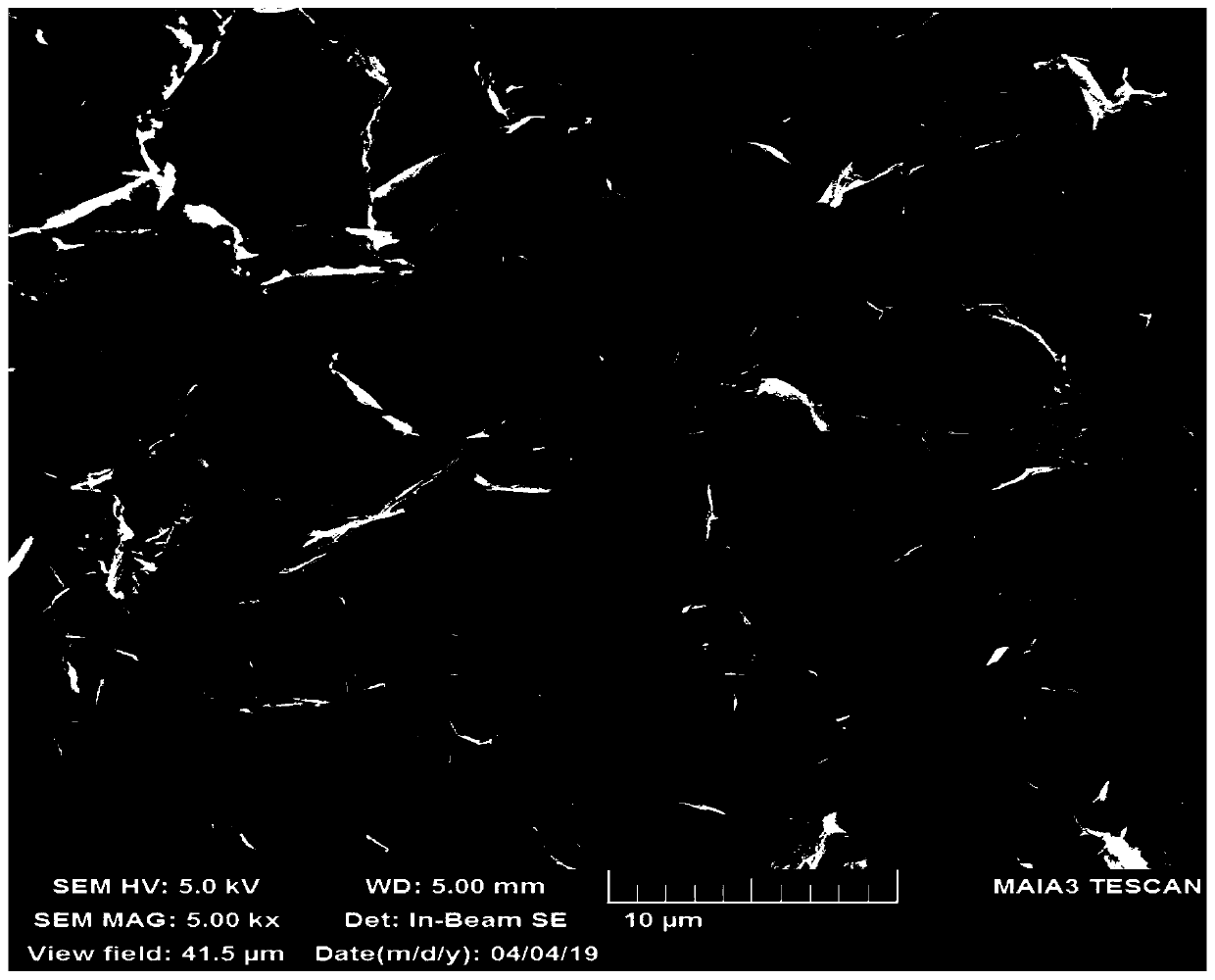

[0095] The water-based graphene conductive coating prepared in Example 1 of the present invention was characterized.

[0096] see figure 2 , figure 2 The SEM scanning electron micrograph of the graphene water-based conductive coating prepared for Example 1 of the present invention.

[0097] Depend on figure 2 It can be seen that in the graphene water-based conductive coating prepared by the present invention, the graphene sheets are relatively large, and the particle size distribution is between 10 an...

Embodiment 2

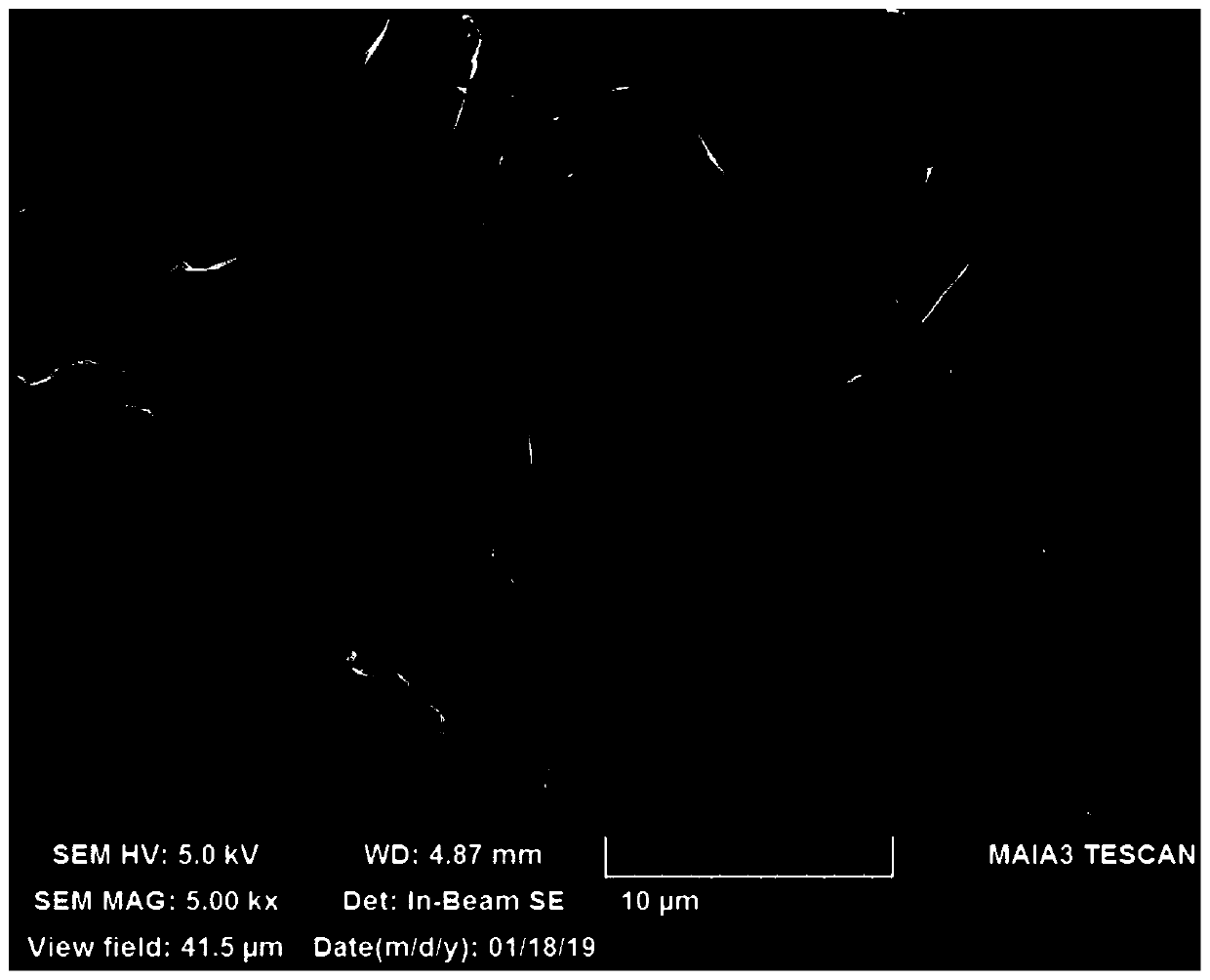

[0099] Weigh 20 parts of deionized water, 2.0 parts of expanded graphite, 2.0 parts of supramolecular dispersant, 60 parts of water-based acrylic resin, 0.05 part of defoamer, 0.1 part of leveling agent, 0.15 part of wetting agent, anti-flash rust additive 0.25 parts, 0.6 parts of film-forming aid, mix the materials evenly in the high-speed mixer, the speed is 600r / min, and the time is 15min. 4 times, the water-based graphene conductive coating can be obtained by discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| salt spray resistance time | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com