Method for reducing ethyl carbamate in hawthorn fermented wine

A technology for medium urethane and hawthorn wine, which is applied in the field of food processing, can solve the problems that the limit of urethane is not formulated and the content of urethane is not involved, and achieves bright color, reduced content and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

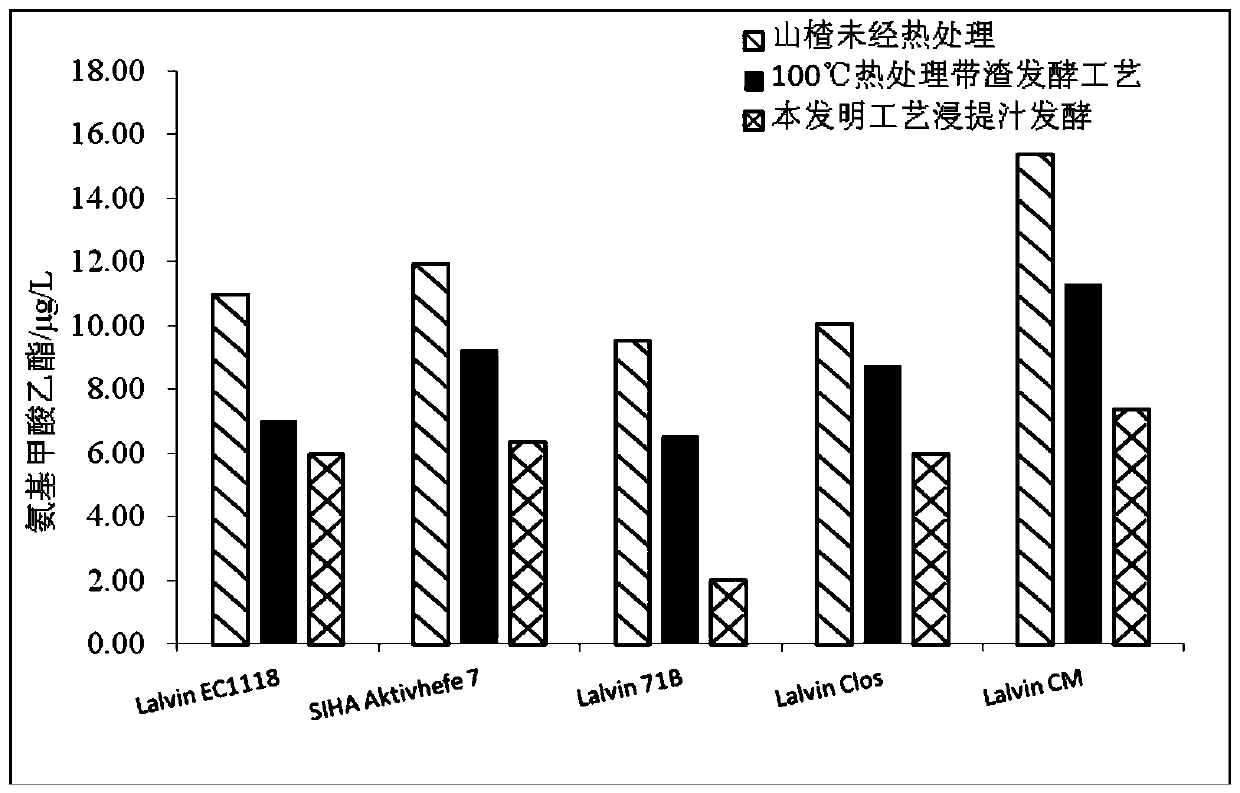

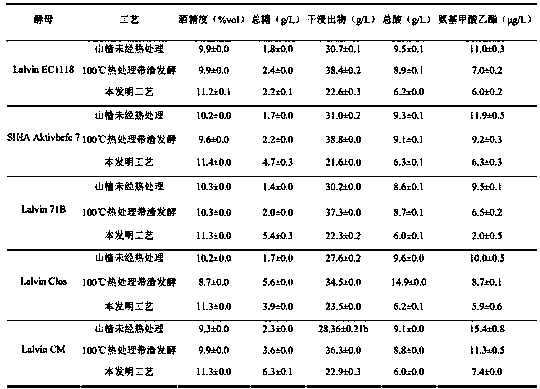

[0021] Embodiment 1 uses 5 kinds of Saccharomyces cerevisiae to brew hawthorn wine respectively by the method of the present invention

[0022] 1) Choose healthy hawthorn, wash with running water and dry the water for later use.

[0023] 2) Hawthorn is broken, and the broken particle size is 0.5-1cm.

[0024] 3) Add demineralized water to the crushed hawthorn at a mass ratio of hawthorn: water = 1:1.5 (the demineralized water is obtained by mixing pure water: tap water at a volume ratio of 1:1), mix well and boil at 100°C for 30 minutes; separate the juice residue to obtain Hawthorn extract juice;

[0025] 4) Prepare an aqueous white granulated sugar solution containing 80% sugar, heat to boil, and boil to obtain a transparent aseptic sugar solution.

[0026] 5) Add the aseptic sugar solution with 80% sugar content boiled in step 4) to the hawthorn extract juice, so that the sugar content in the hawthorn aqueous solution is 20%.

[0027] 6) Cool the hawthorn juice with a su...

Embodiment 2

[0030] Example 2 Using the five kinds of Saccharomyces cerevisiae in Example 1 to brew hawthorn wine according to the process of heat treatment with slag fermentation at 100°C

[0031] 1) Choose healthy hawthorn, wash with running water and dry the water for later use.

[0032] 2) Hawthorn is broken, and the broken particle size is 0.5-1cm.

[0033] 3) Add demineralized water (pure water: tap water = 1:1 volume ratio) to the crushed hawthorn at a mass ratio of hawthorn: water = 1:1.5, mix well and boil at 100°C for 30 minutes.

[0034] 4) Prepare an aqueous white granulated sugar solution containing 80% sugar, heat to boil, and boil to obtain a transparent aseptic sugar solution.

[0035] 5) Add the sterilized sugar liquid with a sugar content of 80% boiled in step 4) to the hawthorn-water solution, so that the sugar content in the hawthorn water solution is 20%.

[0036] 6) Cool the hawthorn-water solution after adding the sugar solution to 18°C, inoculate the hawthorn-wate...

Embodiment 3

[0039] Example 3 Use the five kinds of Saccharomyces cerevisiae in Example 1 to brew hawthorn wine according to the existing technology of hawthorn raw materials without heat treatment (the existing technology does not involve heating to prepare aseptic sugar solution and immediately separate hawthorn peel dregs and yeast puree)

[0040] 1) Choose healthy hawthorn, wash with running water and dry the water for later use.

[0041] 2) Hawthorn is broken, and the broken particle size is 0.5-1cm.

[0042] 3) Add the crushed hawthorn to demineralized water (purified water: tap water = 1:1 volume ratio) at a mass ratio of hawthorn: water = 1:1.5, and mix well.

[0043] 4) Prepare an aqueous white granulated sugar solution containing 80% sugar, heat to boil, and boil to obtain a transparent aseptic sugar solution.

[0044] 5) Add the sterilized sugar liquid with a sugar content of 80% boiled in step 4) to the hawthorn-water solution, so that the sugar content in the hawthorn water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com