A kind of preparation and modification method of digital pcr chip

A chip and digital technology, applied in the field of digital PCR chip preparation and modification, can solve the problems of high cost, complicated digital PCR chip processing technology, low chip throughput, etc., to reduce processing costs, improve hole efficiency, and reduce processing The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of digital PCR chip, concrete steps are as follows:

[0038] Step 1: Select silicon material as the base layer of the chip;

[0039] Step 2: After polishing one side of the base layer of the chip, the polymer material is embedded on the polished surface of the base layer of the chip at 65°C using a laminating machine, and then the protective film on the surface of the polymer material is removed to form a polymer material panel; The thickness of the molecular material is 25 μm; the polymer material is a photosensitive thick epoxy resin sheet, and the photosensitive thick epoxy resin sheet is composed of a photoresist containing cation-cured modified epoxy resin; the photoresist of the epoxy resin contains no antimony photoacid generator and is prepared in a strictly controlled solvent-free process;

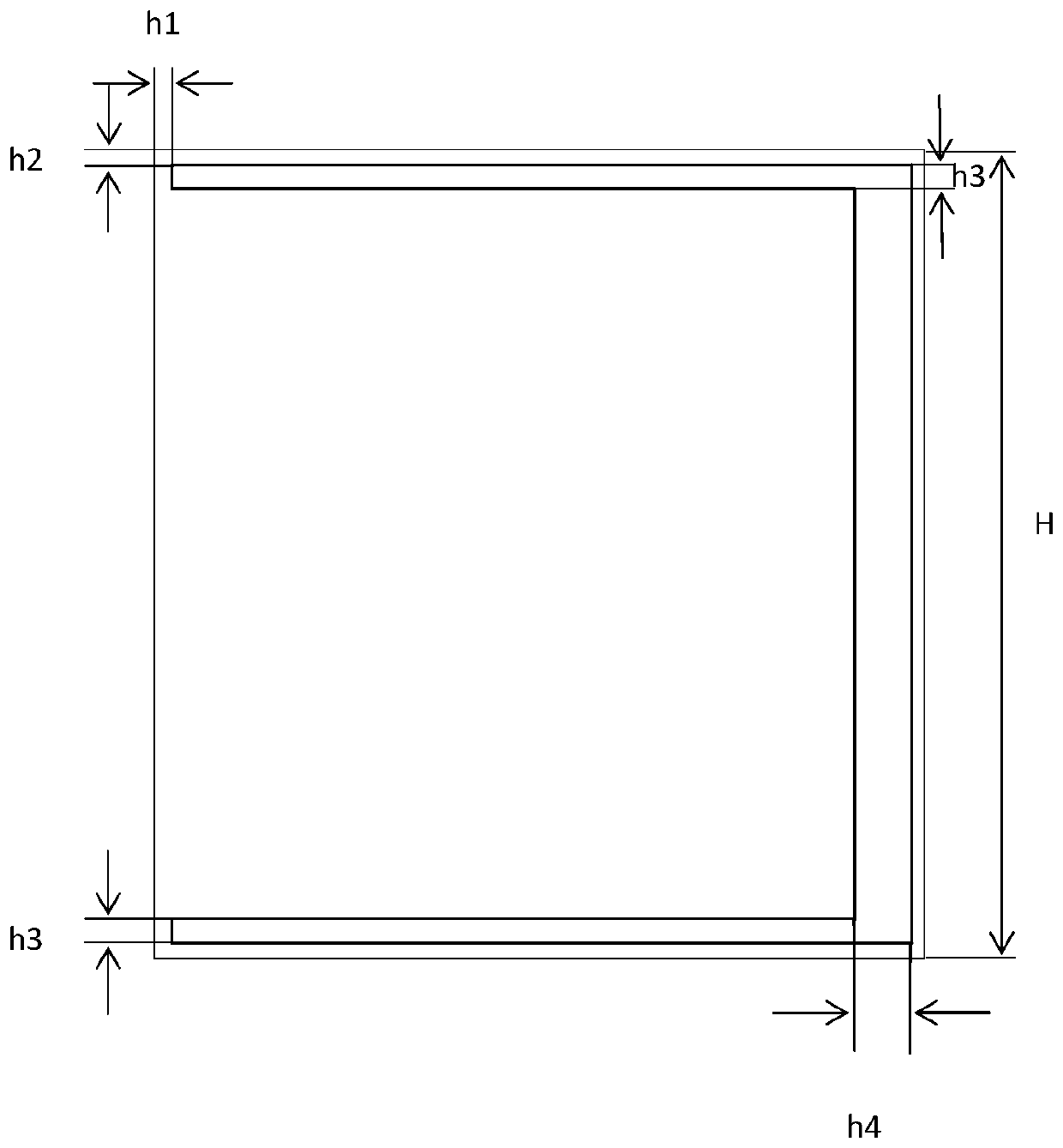

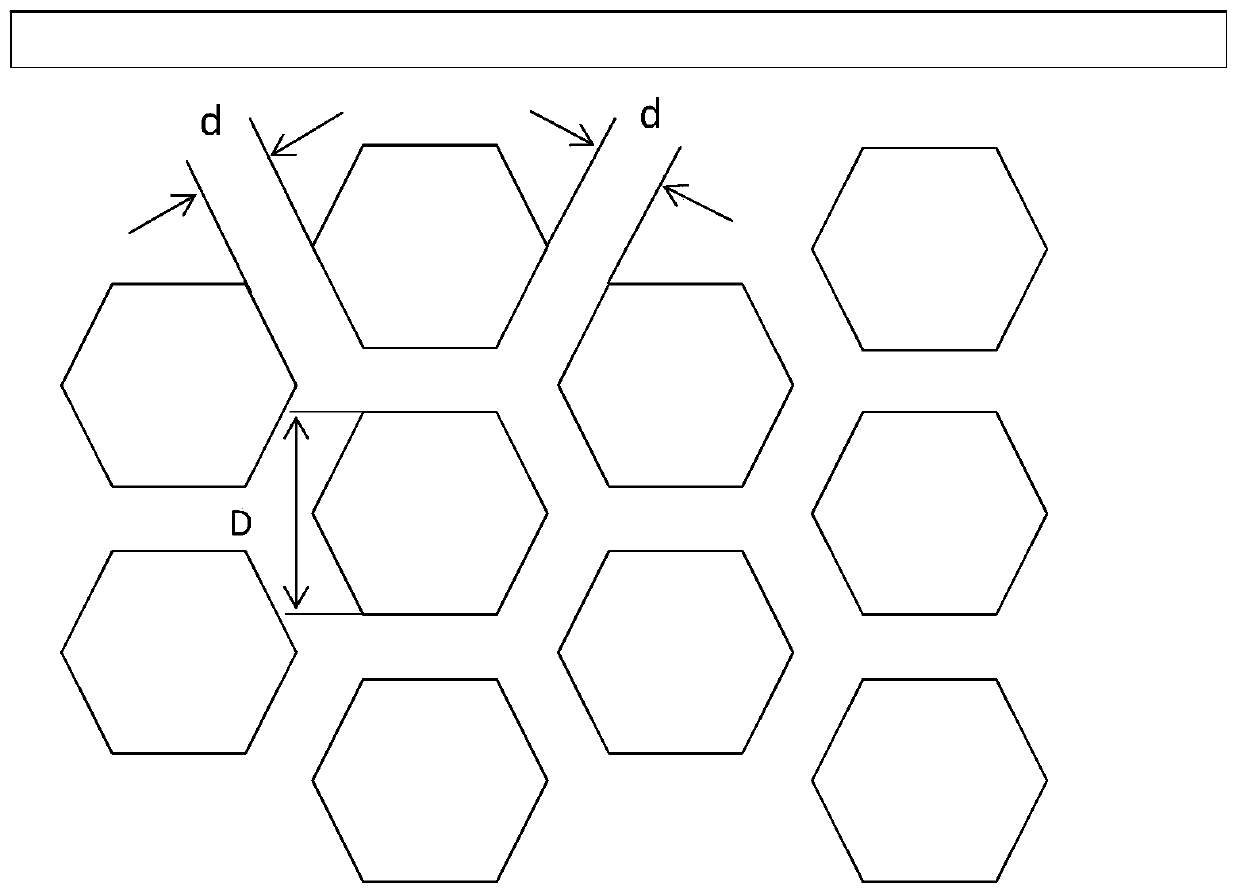

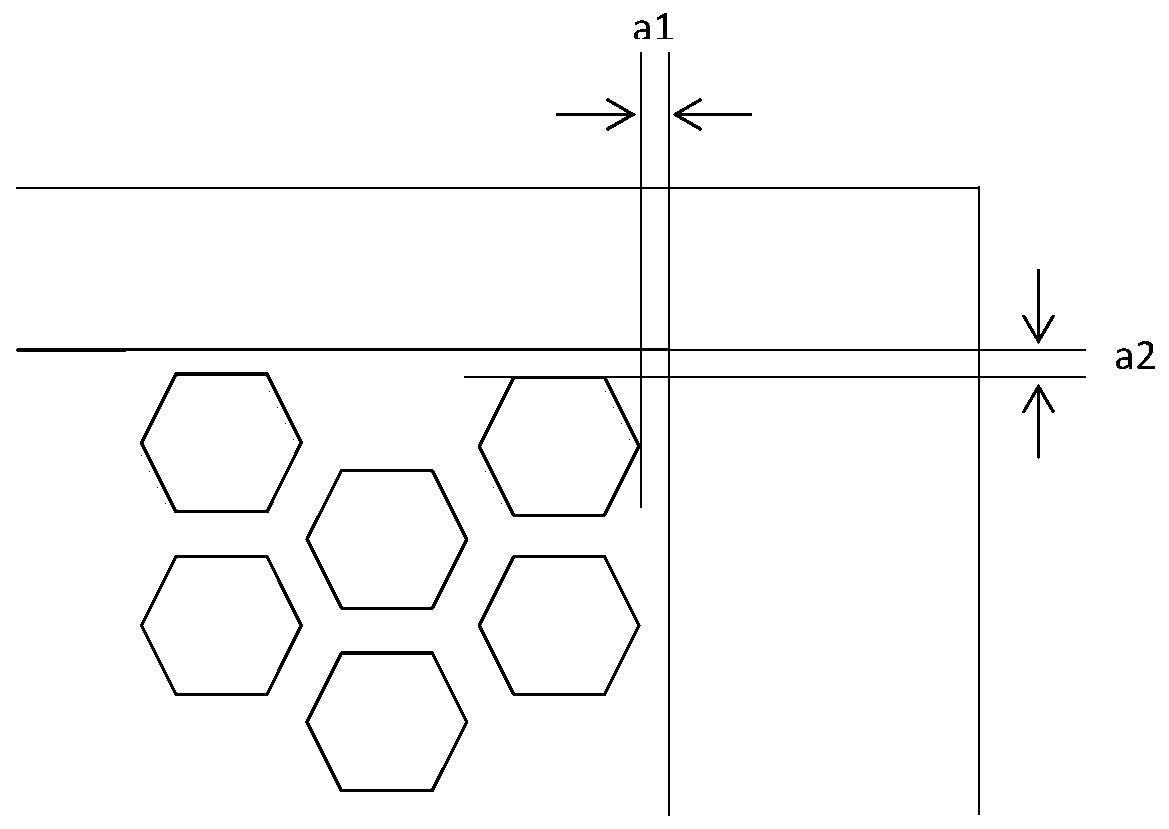

[0040] Step 3: Baking the polymer material panel in step 2 at 95°C for 10 minutes, and then exposing on the exposure machine to form a close-p...

Embodiment 2

[0047] Compared with Example 1, the thickness of the polymer material in this example is 20 μm, and in the regular hexagonal pattern array, the distance D between the opposite sides of the regular hexagon is 0.03mm, and the gap d of the regular hexagon is 0.013mm; The widths a2 and a3 of the upper and lower grooves are 0.02775 mm, and the widths a4 and a1 of the left and right grooves are 0.0248 mm. The modification method of digital PCR in this embodiment is:

[0048] S1, the chip obtained in step 5 is subjected to plasma treatment by a plasma machine to obtain chip A,

[0049] S2. Soak the chip A in step S1 in bovine serum albumin, then dry it and use it directly.

[0050] The concentration range of bovine serum albumin in the step S2 is 10 mg / mL.

Embodiment 3

[0052] Compared with Example 1, the thickness of the polymer material in this embodiment is 15 μm, and in the regular hexagonal pattern array, the distance D between the opposite sides of the regular hexagon is 0.022mm, and the gap d of the regular hexagon is 0.013mm; The widths a2 and a3 of the upper and lower grooves are 0.02825 mm, and the widths a4 and a1 of the left and right grooves are 0.02015 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com