Pretreatment method for solid food sample based on ionic liquid

A technique for sample pretreatment and ionic liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 preparation solution

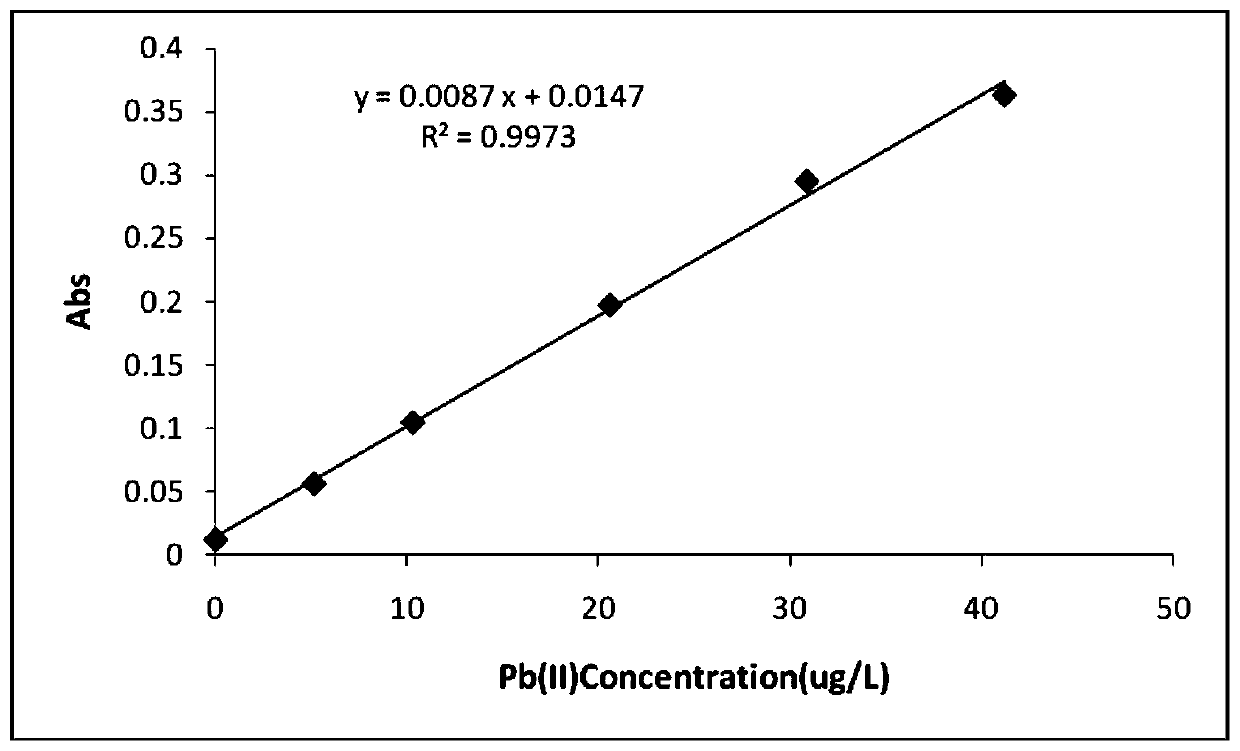

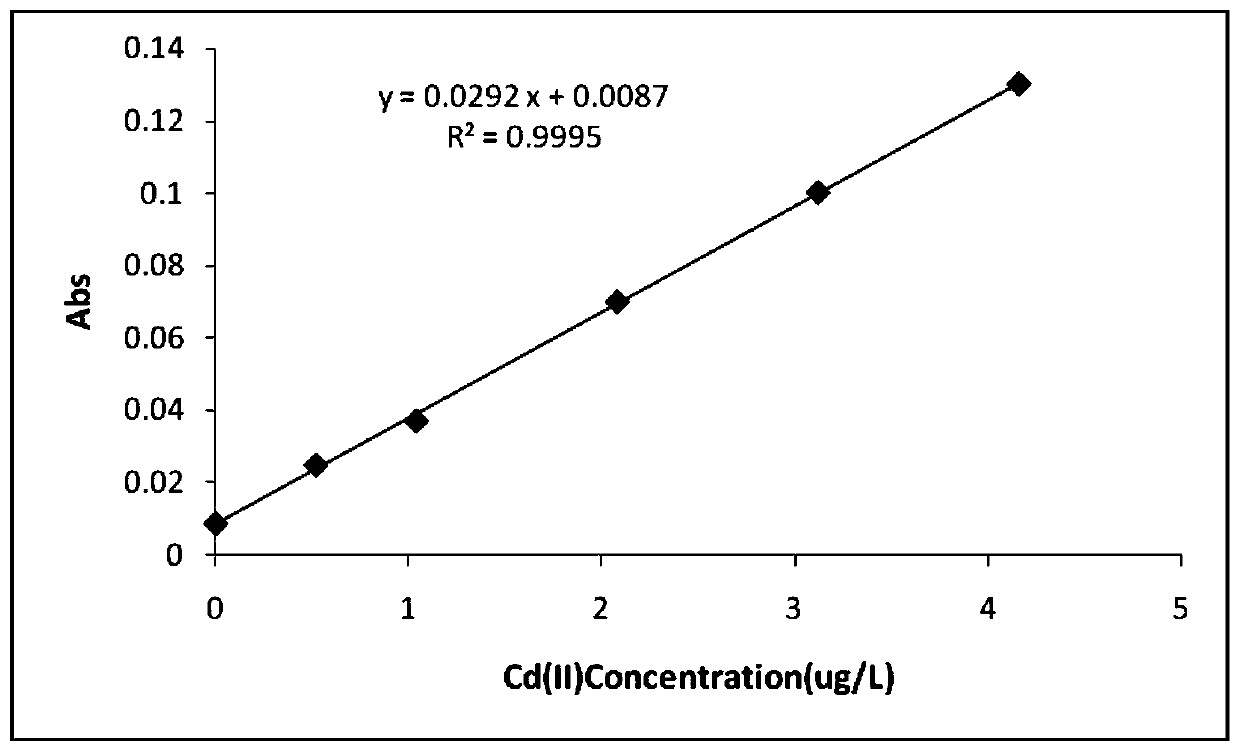

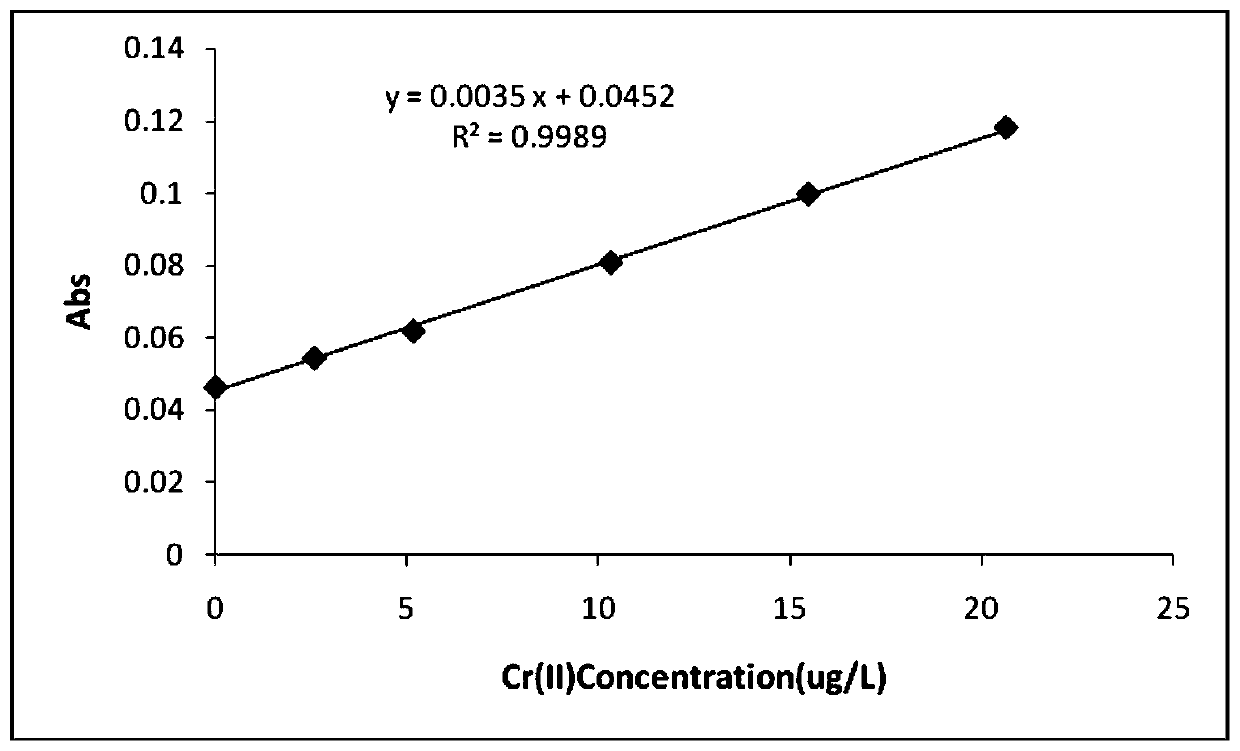

[0051] Mixed standard stock solution: pipette 2mL multi-element mixed standard solution (GBW08607: Pb concentration is 1.03μg / g, Cd concentration is 0.104μg / g, Cr concentration is 0.516μg / g). Dissolve in 25mL of deionized water and shake well to obtain a mixed standard stock solution with a Pb concentration of 82.4 μg / L, a Cd concentration of 8.32 μg / L, and a Cr concentration of 41.28 μg / L.

Embodiment 2

[0052] Example 2 Using ionic liquid and nitric acid to sample pretreatment

[0053] HNO 3 It is a commonly used solvent when digesting samples. The wet digestion of food solid samples usually requires 14mL concentrated nitric acid and 1mL perchloric acid. The temperature is between 200°C and 300°C. into the environment. The sample selected in this embodiment is dried fungus, concentrated HNO 3 The dosage is 0.5mL. The applicant found through experiments that when the heating temperature is higher than 200°C, the sample will be carbonized in the ionic liquid [Bmim]-Cl solution, so the heating temperature selected in this embodiment is 170°C, and the reaction will be free of solid particles in the solution, and the solution will be The light-colored and bright shape is considered to be completely dissolved, and the dissolution status is shown in Table 4.

[0054] The dissolving time of table 4 food solid sample

[0055]

[0056] It can be seen from Table 4 that the solut...

Embodiment 3

[0057] Example 3 Pretreatment of Food Solid Samples Based on Ionic Liquids

[0058] Accurately weigh 3g of ionic liquid [Bmim]-Cl and place it in a beaker, heat the beaker to 90°C to melt the ionic liquid [Bmim]-Cl crystals, remove and cool after completely melting, and accurately weigh 0.2g of sample powder into the beaker , the sample was evenly dispersed on the liquid surface, and 0.5mL concentrated HNO was added 3 , heated to 160°C, and dissolved for 5 minutes. After it dissolves, add deionized water to precipitate the cellulose, and set the volume to 50mL. After the precipitated cellulose settles naturally, take part of the upper clear night, and use graphite furnace atomic absorption spectrometry to detect it. The results are shown in Table 5. Show.

[0059] Table 5 Analysis result samples after pretreatment

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com