Titanium dioxide nanofiber-nanotube with hierarchical structure and preparation method thereof

A technology of titanium dioxide and nanofibers, applied in the field of nanomaterials, can solve the problems of limited popularization and application, complex reaction process, and low stability of product hierarchical structure, and achieve the effect of high controllable repeatability, simplicity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

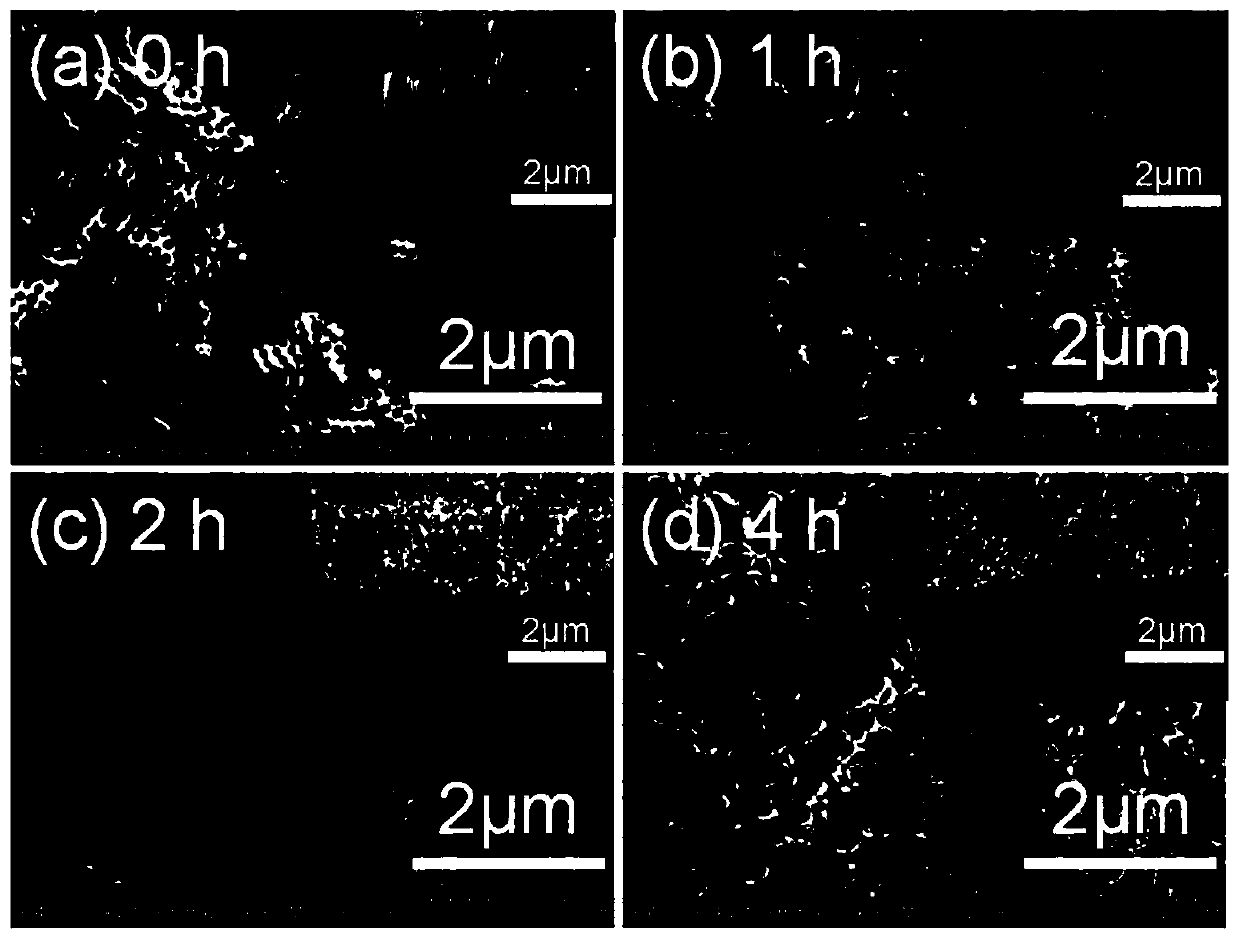

[0032] like figure 1 As shown, a titanium dioxide nanofiber-nanotube with a hierarchical structure includes honeycomb titanium dioxide nanotubes, the surface of the titanium dioxide nanotubes is evenly coated with titanium dioxide nanofibers, and the diameter of the titanium dioxide nanotubes is 100- 150 nanometers, the tube length is 5-10 microns, and the thickness of the titanium dioxide nanofiber is 5-20 nanometers. .

Embodiment 2

[0034] A method for preparing titanium dioxide nanofibers-nanotubes with a hierarchical structure, comprising the steps of,

[0035] S1. Put the titanium sheet in an acidic polishing solution and polish it for 20s. The acidic polishing solution is uniformly mixed with hydrofluoric acid: nitric acid: water according to the volume ratio of 1:1:2, immersed in deionized water for 10s, and then ultrasonically cleaned Until the surface of the titanium sheet is uniformly silver-white and matte;

[0036] S2. Configure 0.1 mol / L ammonium fluoride-ethylene glycol solution, dissolve 0.74g ammonium fluoride in 2ml deionized water, pour ethylene glycol to 200ml under magnetic stirring conditions, and continue stirring at 25°C for 15min , until there is no insoluble matter, the electrolyte is obtained;

[0037]S3. Pour the electrolyte obtained in S2 into the electrolytic cell, use the platinum sheet as the cathode, and the polished titanium sheet as the anode, and react at 25°C for 4 hours...

Embodiment 3

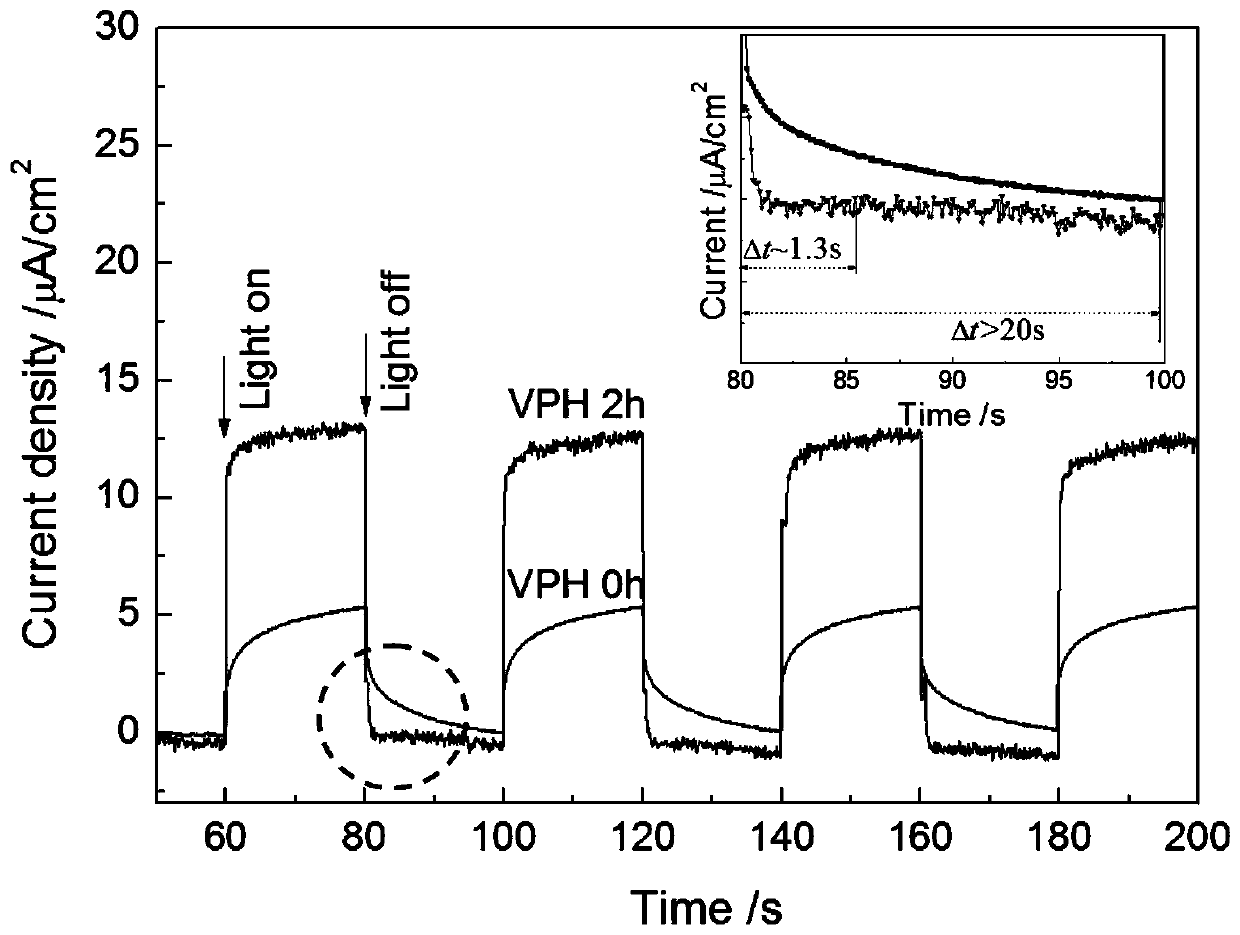

[0040] The difference between this example and Example 2 lies in "in S4, at 150°C, react for 2 hours".

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com