Photovoltaic material containing thiophene ring and preparation method of photovoltaic material

A technology for optoelectronic materials and organic optoelectronic materials, which is applied to the field of optoelectronic materials containing thiophene rings and their preparation, can solve the problems of high production cost, unsatisfactory optoelectronic properties, low conversion efficiency and the like, and achieves low production cost and excellent optoelectronic properties. , the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

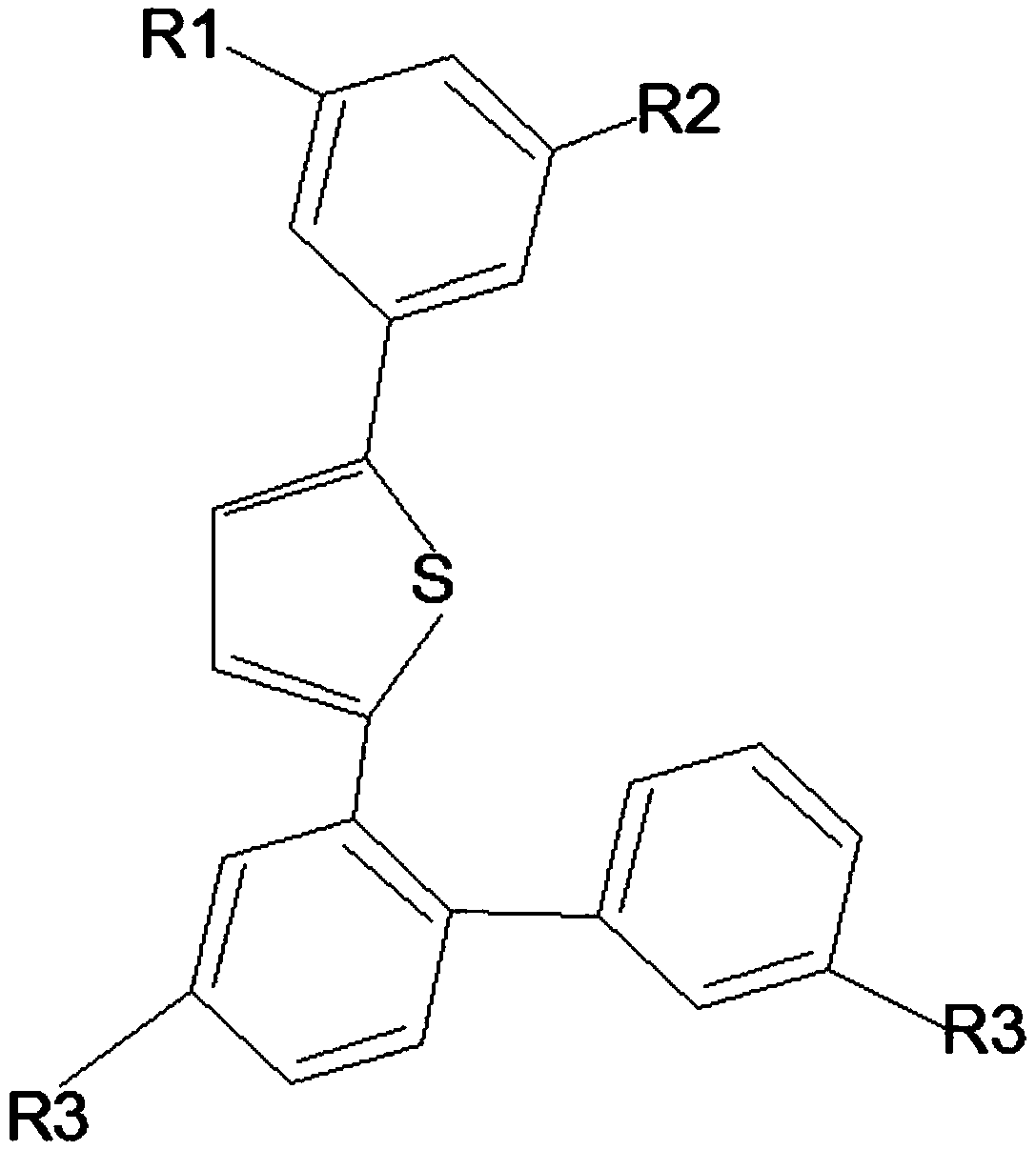

[0037] A kind of photoelectric material containing thiophene ring, its structural formula is as follows:

[0038]

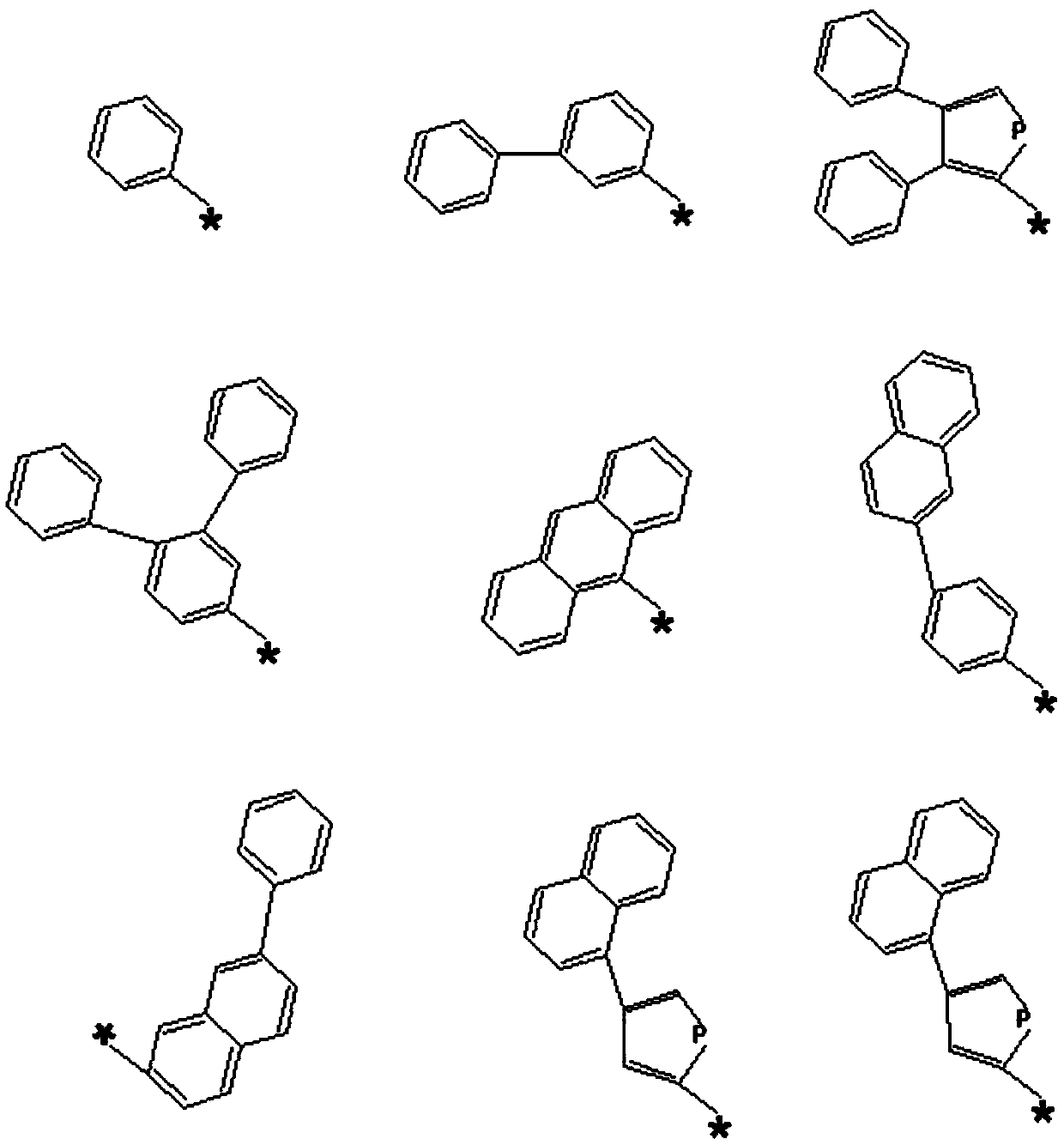

[0039] Wherein, R1 and R2 are each independently any one of the following groups:

[0040]

[0041] R3 is isopropyl or t-butyl.

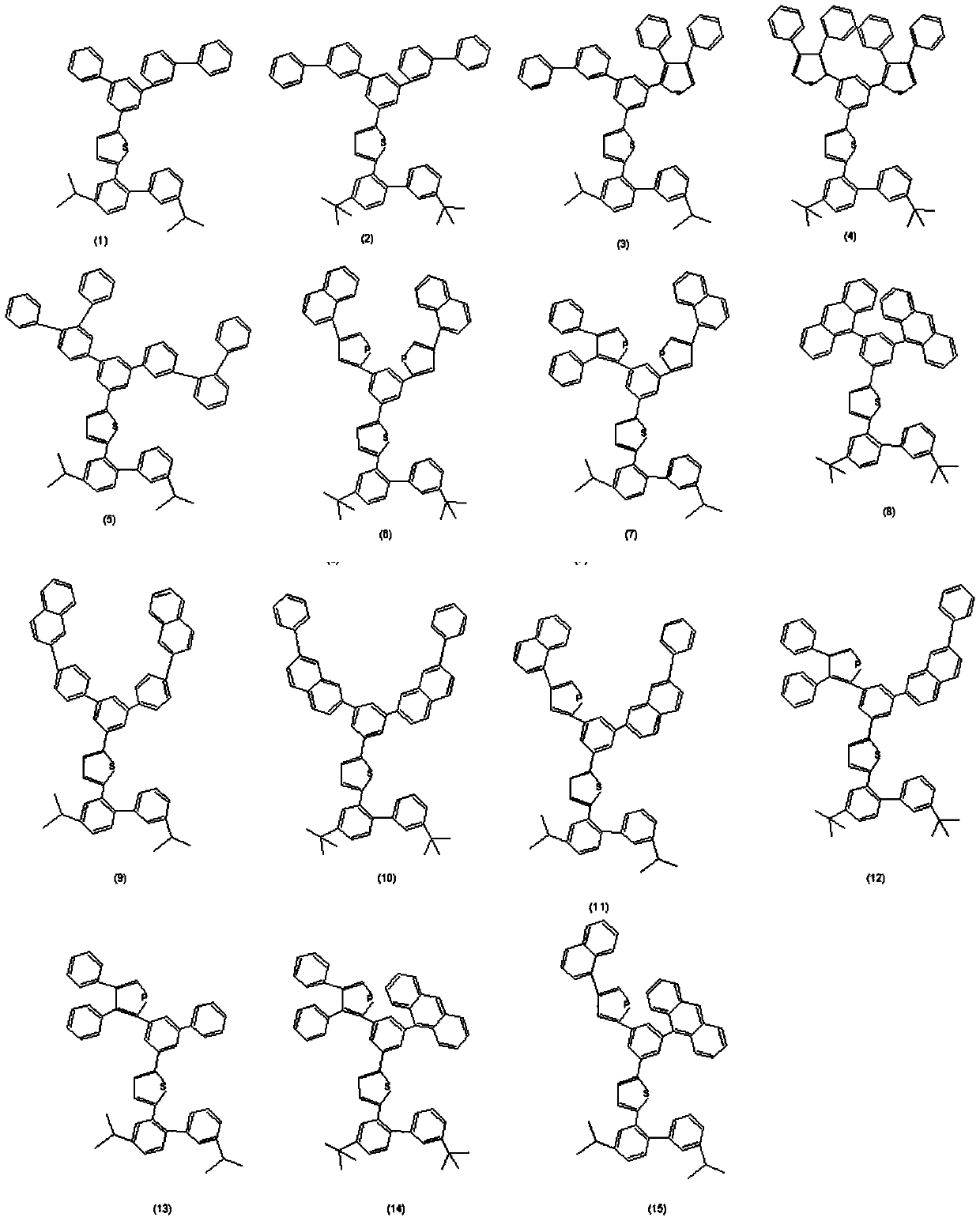

[0042] Organic optoelectronic material, its structural formula is:

[0043]

[0044] A kind of photoelectric material containing thiophene ring, its preparation method comprises the following steps:

[0045] a. Add the raw materials into the organic solvent, lower the temperature to -65°C, add n-butyllithium n-hexane solution into the organic solvent, and keep it warm for 1.5 hours to obtain a reaction system containing intermediates for later use;

[0046] The structural formula of raw material I is:

[0047]

[0048] The structural formula of intermediate I is:

[0049]

[0050] b. Add the reaction system of the intermediate in step a to carbon tetrachloride, then add R1 and R2 substituent raw materials to R1 and R...

Embodiment 2

[0061] A kind of photoelectric material containing thiophene ring, its structural formula is as follows:

[0062]

[0063] Wherein, R1 and R2 are each independently any one of the following groups:

[0064]

[0065] R3 is isopropyl or t-butyl.

[0066] Organic optoelectronic material, its structural formula is:

[0067]

[0068] A kind of photoelectric material containing thiophene ring, its preparation method comprises the following steps:

[0069] a. Add the raw materials into the organic solvent, lower the temperature to -65°C, add n-butyllithium n-hexane solution into the organic solvent, keep the reaction for 1.9 hours, and obtain the reaction system containing the intermediate, and set it aside;

[0070] The structural formula of raw material I is:

[0071]

[0072] The structural formula of intermediate I is:

[0073]

[0074] b. Add the reaction system of the intermediate in step a to carbon tetrachloride, then add R1 and R2 substituent raw materials t...

Embodiment 3

[0085] A kind of photoelectric material containing thiophene ring, its structural formula is as follows:

[0086]

[0087] Wherein, R1 and R2 are each independently any one of the following groups:

[0088]

[0089] R3 is isopropyl or t-butyl.

[0090] Organic optoelectronic material, its structural formula is:

[0091]

[0092] A kind of photoelectric material containing thiophene ring, its preparation method comprises the following steps:

[0093] a. Add the raw materials into the organic solvent, lower the temperature to -65°C, add n-butyllithium n-hexane solution into the organic solvent, keep the reaction for 2.2 hours, and obtain the reaction system containing the intermediate, and set it aside;

[0094] The structural formula of raw material I is:

[0095]

[0096] The structural formula of intermediate I is:

[0097]

[0098] b. Add the reaction system of the intermediate in step a to carbon tetrachloride, then add R1 and R2 substituent raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com