Preparation method, product and application of anti-radiation porous fiber with oriented hole structure

A technology for porous fibers and radiation protection, which is applied in the field of preparation of radiation protection porous fibers, can solve the problems of increased incidence of cancer and decreased number of white blood cells, and achieves the effects of excellent radiation protection performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution. Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml. 0.02 g of carbon nanotube powder was dissolved in 20 ml of 1% sodium dodecylbenzenesulfonate solution.

[0074] After mixing 20ml silk protein solution, 10ml chitosan solution and 20ml carbon nanotube solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1, and the mass ratio of silk protein to carbon nanotubes is 9:1. The mass ratio of the tube is 225:1.

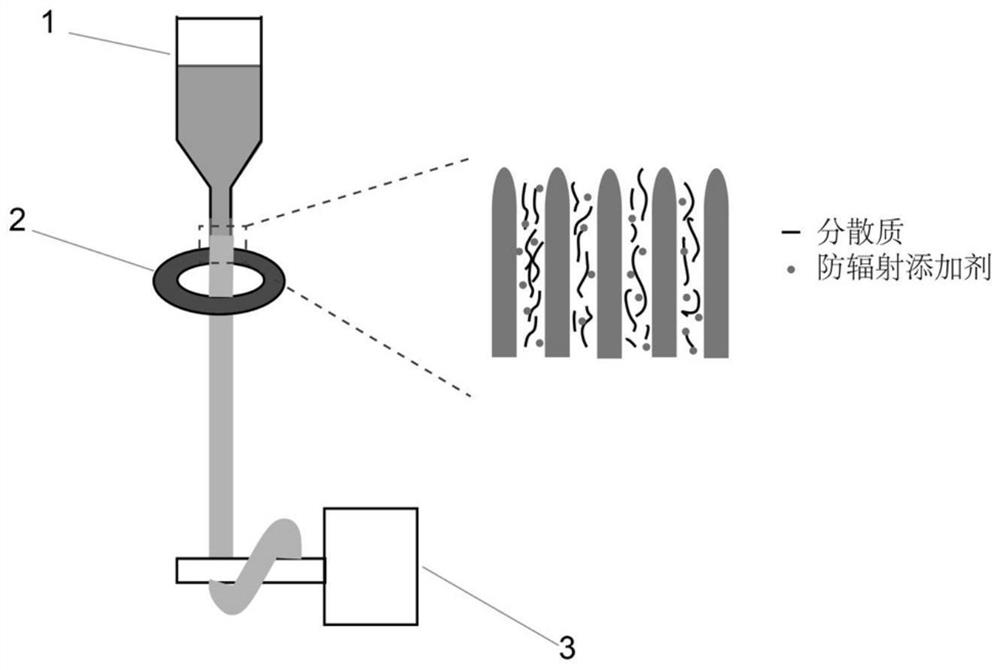

[0075] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperat...

Embodiment 2

[0085] (1) Cut 4.5g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 20ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution. Dissolve 0.5 g of chitosan powder in 10 ml of 1% acetic acid solution, stir for 30 min at a speed of 800 rpm / min to make it evenly mixed, and prepare a chitosan solution with a concentration of 50 mg / ml. 0.04 g of carbon nanotube powder was dissolved in 20 ml of 1% sodium dodecylbenzenesulfonate solution.

[0086] After mixing 20ml silk protein solution, 10ml chitosan solution and 20ml carbon nanotube solution evenly, centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 9:1, and the mass ratio of silk protein to carbon nanotubes is 9:1. The mass ratio of the tube is 225:2.

[0087] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperat...

Embodiment 3

[0092] (1) Cut 2.25g of natural cocoons, boil and dry in 1% sodium carbonate solution, dissolve in 10ml of 9mol / ml lithium bromide solution, and dialyze for 24h to prepare a 22.5% silk protein solution.

[0093] Add 0.1 g of acetic acid to 10 ml of nano-silver solution with a concentration of 100 ppm (particle size 1-2 nm, Luoyang Oulun Environmental Protection Technology Co., Ltd.), and mix well.

[0094] Dissolve 0.5 g of chitosan powder in the above acetic acid solution, stir at 800 rpm / min for 30 min to mix evenly, and prepare a chitosan solution with a concentration of 50 mg / ml.

[0095] Mix 10ml of the above-mentioned silk protein solution and 10ml of chitosan solution evenly, and centrifuge to remove air bubbles to obtain a homogeneous solution, wherein the mass ratio of silk protein to chitosan is 4.5:1.

[0096] (2) Put the mixed solution in the syringe, extrude the solution through the extrusion pump, place the copper ring in a low-temperature reaction bath (-60°C), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com