Method for detecting aflatoxin M1 in cheese

A kind of aflatoxin and cheese technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of affinity column, influence of immunoaffinity column efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

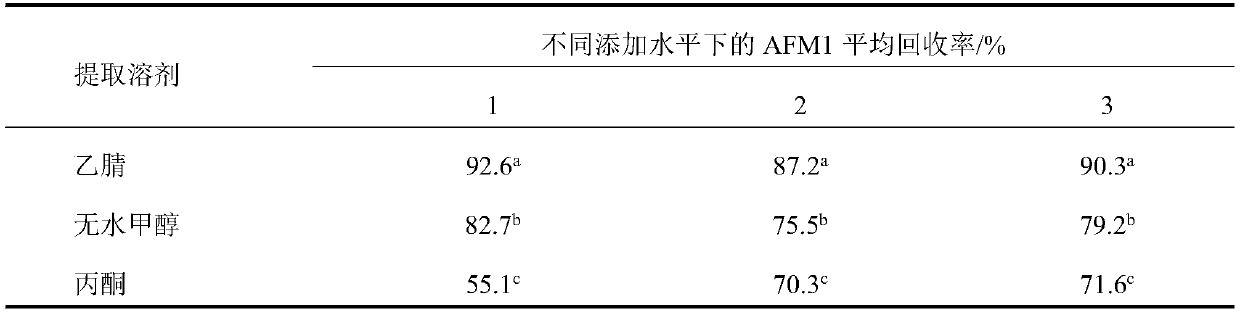

example 1

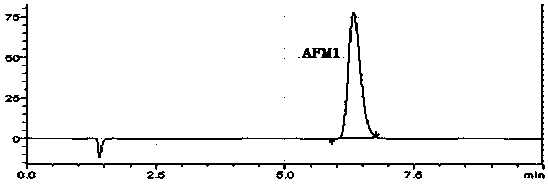

[0025] Weigh 5g of cheese sample into a homogenizer cup, add 30mL of acetonitrile with a concentration of 1ng / mL, place in a homogenizer, homogenize for 5min, collect the liquid phase, centrifuge (8000r / min, 10min), collect the supernatant, Filter through filter paper. The filtrate was collected and transferred to a 250 mL separatory funnel. Add 30 mL of petroleum ether into the separatory funnel, shake for 2 minutes, and discard the petroleum ether layer after the layers are separated. Repeat the extraction with petroleum ether twice. Transfer the lower layer solution to a 100mL round bottom flask, concentrate under reduced pressure at 45°C to about 2mL, pour the concentrated solution into a 50mL volumetric flask and add water to the mark.

[0026] Rinse the HLB solid-phase extraction column with 5mL acetonitrile first, and then wash the column with 5mL water. Then put the extract liquid of AFM1 on the column for extraction. After the sample liquid is completely extracted,...

example 2

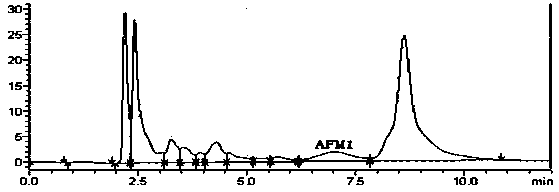

[0028] Weigh 5g of cheese sample into a homogenizer cup, add 30mL of acetonitrile with a concentration of 4ng / mL, place in a homogenizer, homogenize for 5min, collect the liquid phase, centrifuge (8000r / min, 10min), collect the supernatant, Filter through filter paper. The filtrate was collected and transferred to a 250 mL separatory funnel. Add 30 mL of petroleum ether into the separatory funnel, shake for 2 minutes, and discard the petroleum ether layer after the layers are separated. Repeat the extraction with petroleum ether twice. Transfer the lower layer solution to a 100mL round bottom flask, concentrate under reduced pressure at 45°C to about 2mL, pour the concentrated solution into a 50mL volumetric flask and add water to the mark.

[0029] Rinse the HLB solid-phase extraction column with 5mL acetonitrile first, and then wash the column with 5mL water. Then put the extract liquid of AFM1 on the column for extraction. After the sample liquid is completely extracted,...

example 3

[0031] Weigh 5g of cheese sample into a homogenizer cup, add 30mL of acetonitrile with a concentration of 1ng / mL, place in a homogenizer, homogenize for 5min, collect the liquid phase, centrifuge (8000r / min, 10min), collect the supernatant, Filter through filter paper. The filtrate was collected and transferred to a 250 mL separatory funnel. Add 30 mL of petroleum ether into the separatory funnel, shake for 2 minutes, and discard the petroleum ether layer after the layers are separated. Repeat the extraction with petroleum ether twice. Transfer the lower layer solution to a 100mL round bottom flask, concentrate under reduced pressure at 45°C to about 2mL, pour the concentrated solution into a 50mL volumetric flask and add water to the mark.

[0032] Rinse the HLB solid-phase extraction column with 5mL acetonitrile first, and then wash the column with 5mL water. Then put the extract liquid of AFM1 on the column for extraction. After all the sample liquid has been extracted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com