Efficient air-cooling gas-phase liquid nitrogen biological storage apparatus, use method and applications thereof

A storage device and liquid nitrogen technology, which can be used in applications, preservation of human or animal bodies, animal husbandry, etc., can solve the problems of large temperature fluctuations inside the tank and large temperature differences between the top and bottom of the tank, so as to avoid liquid nitrogen overflow and balance Temperature, the effect of high-efficiency cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

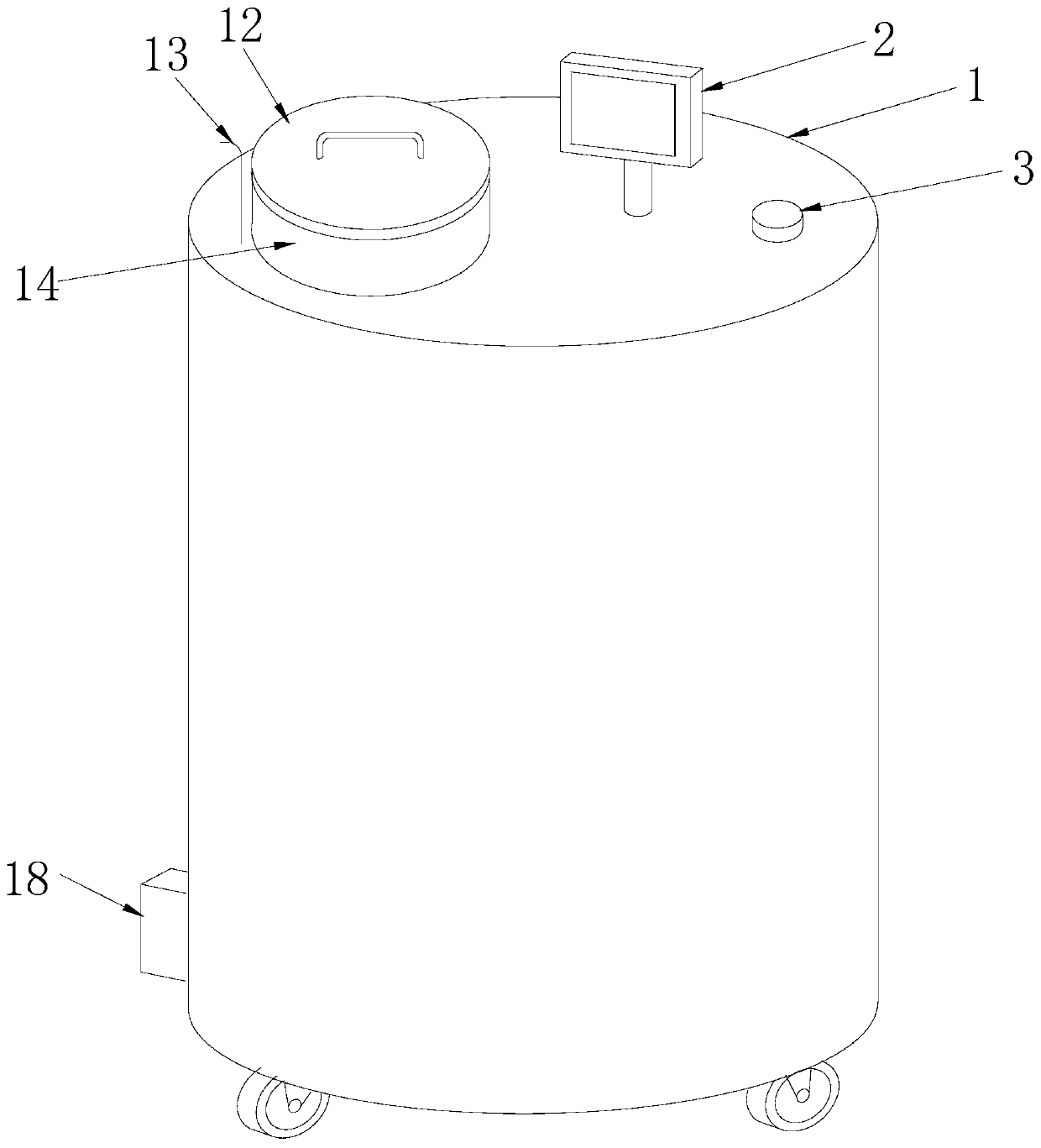

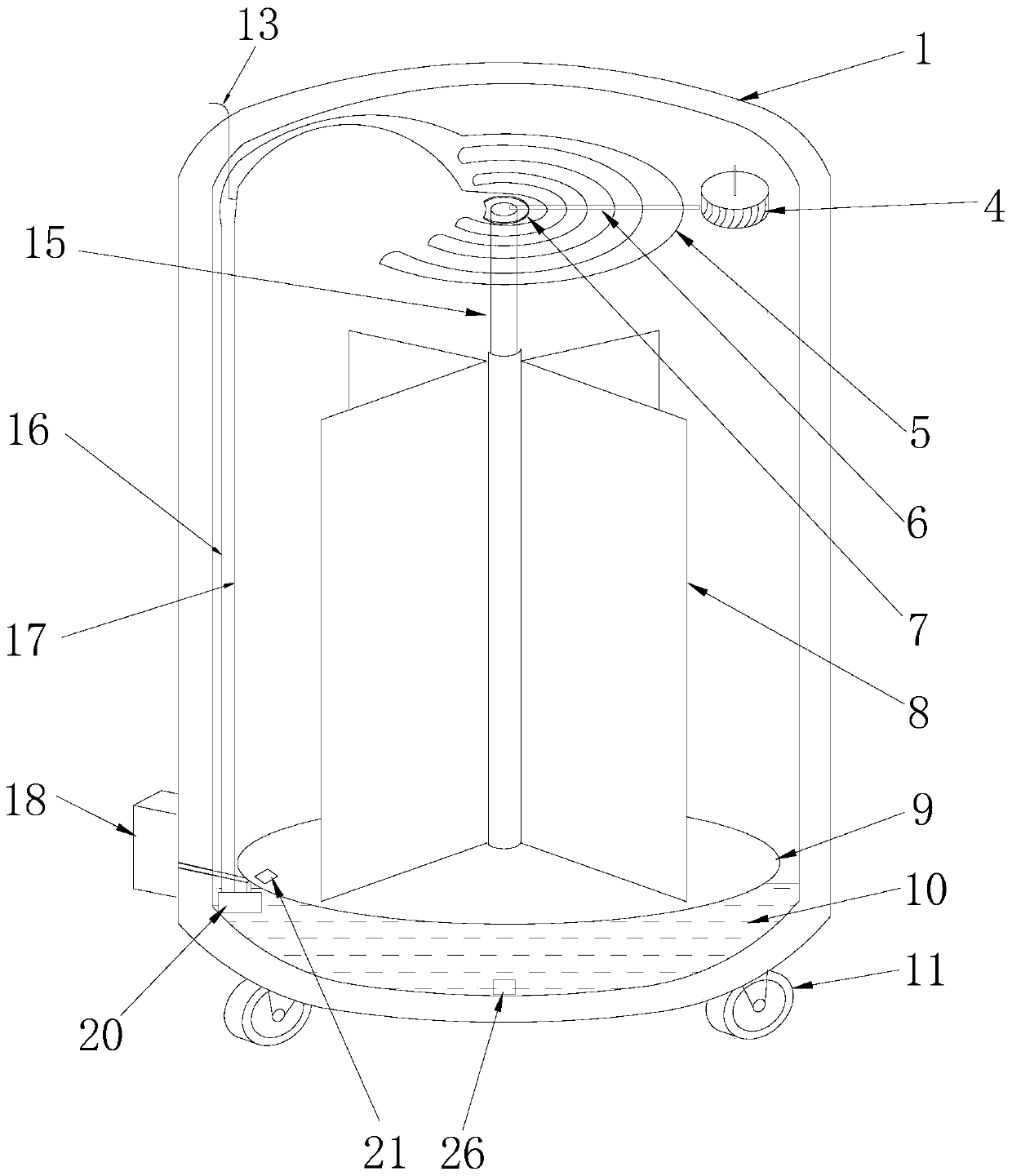

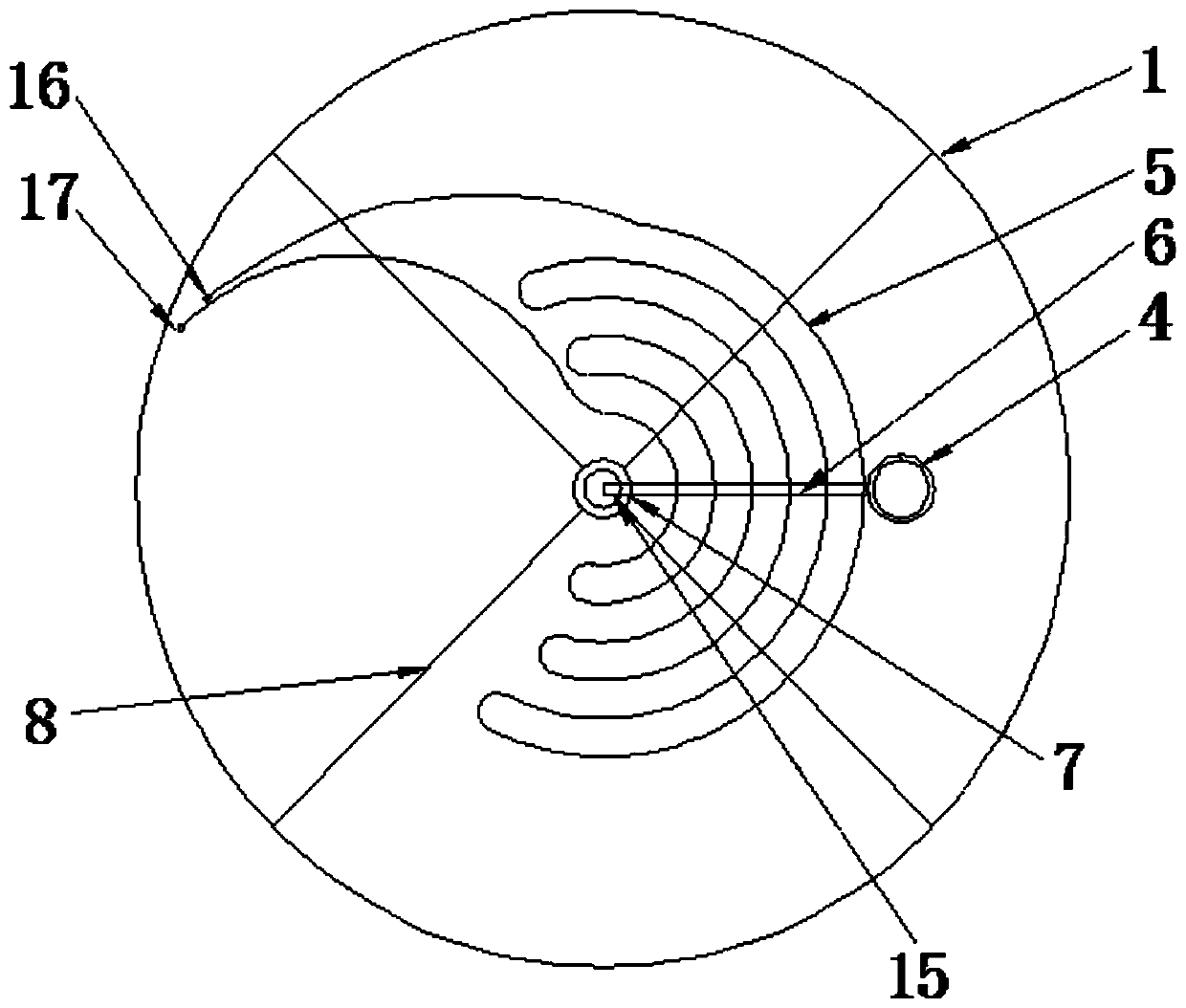

[0030] Embodiment 1: The high-efficiency air-cooled gas-phase liquid nitrogen biological storage device in this embodiment consists of a tank body 1, a control display 2, a centrifugal fan 4, a liquid nitrogen coil 5, a sample turntable 9, a central axis 15, a grid 8 and a cryogenic pump 20; the centrifugal fan 4, the liquid nitrogen coil 5, the sample turntable 9, the central axis 15, the grid 8 and the cryogenic pump 20 are arranged inside the tank body 1, the top of the tank body 1 is provided with an upper cover plate, and the control display 2 is fixed On the upper cover plate; the upper cover plate of the tank body 1 is provided with an access opening 14, and the access opening 14 is provided with an access opening cover plate 12;

[0031] The lower part of the tank body 1 is filled with liquid nitrogen 10, the inner bottom of the tank body 1 is provided with a vertical support column 27, the central axis 15 is a hollow cylinder, and the lower end of the central axis 15 i...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the upper cover plate of the tank body 1 is provided with a vacuum layer, and the upper surface of the upper cover plate of the tank body 1 corresponding to the centrifugal fan 4 is provided with First motor 3, the power output shaft of the first motor 3 passes through the vacuum layer of the upper cover plate of the tank body 1 and is connected with the power input shaft of the centrifugal fan 4; the material of the power output shaft of the first motor 3 is low temperature resistant plastic. Other steps and parameters are the same as those in the first embodiment.

[0042] In this embodiment, the motor is externally installed to avoid the influence of additional heat sources on the temperature inside the tank. The power output shaft connected between the motor and the cryogenic pump is made of low-temperature resistant plastic, which avoids the conduction of cold energy inside the tank to th...

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment differs from Embodiment 2 in that: a mechanical seal is provided between the power output shaft of the first motor 3 and the upper cover of the tank body 1 . Other steps and parameters are the same as in the second embodiment. Mechanical seals can prevent liquid nitrogen from overflowing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com