Preparation method of organic modification biochar for treating heavy metal cadmium in wastewater

A technology for treating wastewater and biochar, which is applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, water pollutants, etc., and can solve problems such as threats to human health and safety, strong toxicity of cadmium, and inability to be removed by self-purification, etc. To achieve the effect of improving adsorption efficiency, increasing adsorption sites, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 1 week and crushed through a 0.85 mm sieve. The crushed wheat straw was placed in a crucible and lightly compacted. Then the crucible was placed in a muffle furnace and the temperature was adjusted to 450 °C. ℃, the heating rate is 8℃ / min, carbonize for 5h, take it out after natural cooling to room temperature, wash with 1mol / L HCl, filter and wash with distilled water until neutral, and dry at 75℃ to constant weight, that is Wheat straw biochar can be obtained;

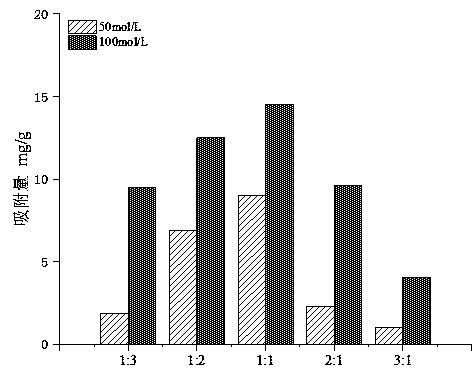

[0030] (2) Preparation of organically modified biochar: A certain amount of chitosan was dissolved in 2% acetic acid, and the solid-to-liquid ratio of chitosan and acetic acid was 1:50, and the wheat straw prepared in step (a) was Biochar is impregnated in chitosan solution, the mass ratio of biochar to chitosan is 3:1, 2:1, 1:1, 1:2, 1:3, after mixing and stirring for 1h, ultrasonic treatment is performed at 40kHz 0.25h, then drop the chit...

Embodiment 2

[0034] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 2 weeks and crushed through a 0.85 mm sieve. The crushed wheat straw was placed in a crucible and lightly compacted. Then the crucible was placed in a muffle furnace and the temperature was adjusted to 500 °C. ℃, the heating rate is 10℃ / min, carbonize for 4h, take it out after natural cooling to room temperature, wash with 0.5mol / L HCl, filter and wash with distilled water until neutral, dry at 80℃ to constant weight, Wheat straw biochar can be obtained;

[0035] (2) Preparation of organically modified biochar: A certain amount of chitosan was dissolved in 2% acetic acid, and the solid-to-liquid ratio of chitosan and acetic acid was 1:70, and the wheat straw prepared in step (a) was Biochar is impregnated in chitosan solution, set the mass ratio of biochar to chitosan as 1:1, mix and stir for 1.5h, then use 50kHz ultrasonic treatment for 0.5h, then inject chitosan-biochar suspension Add it dropwise t...

Embodiment 3

[0040] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 4 weeks and crushed through a 0.85 mm sieve. The crushed wheat straw was placed in a crucible and lightly compacted. Then the crucible was placed in a muffle furnace and the temperature was adjusted to 550 °C. ℃, the heating rate is 12℃ / min, carbonize for 3h, take it out after natural cooling to room temperature, wash with 0.1mol / L HCl, filter and wash with distilled water until neutral, dry at 85℃ to constant weight, Wheat straw biochar can be obtained;

[0041] (2) Preparation of organically modified biochar: A certain amount of chitosan was dissolved in 2% acetic acid, and the solid-liquid ratio of chitosan and acetic acid was 1:90, and the wheat straw prepared in step (a) was Biochar is impregnated in chitosan solution, set the mass ratio of biochar to chitosan as 1:1, mix and stir for 2 hours, then use 60kHz ultrasonic treatment for 1 hour, then add the chitosan-biochar suspension dropwise with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com