Preparation method and application of Bi/Bi2SiO5 photocatalyst

A photocatalyst, 3·5H2O technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the influence of sample stability, limitations, and complex reaction processes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

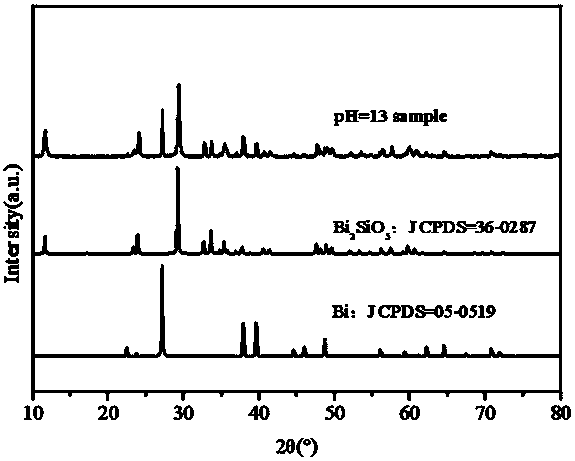

[0022] A Bi / Bi 2 SiO 5 The preparation method of photocatalyst comprises the steps:

[0023] In the first step, Bi(NO 3 ) 3 ·5H 2 O and Na 2 SiO 3 9H 2 O, respectively dissolved in equal volumes of ethylene glycol and deionized water, stirred for 0.5-2 hours to form solutions A and B respectively, mixed with equal volumes of solutions A and B and stirred for 1-3 hours, to form a white suspension C ;

[0024]In the second step, drip the suspension C with a concentration of 1 mol / L NaOH solution to adjust the pH of the solution to 9-14, transfer the reaction solution to a 100-500 mL reactor, and react at 150-200°C for 6-12 h, take out the reactor and cool it down to room temperature, and perform centrifugation, wash the precipitate three times with deionized water and absolute ethanol respectively, then collect the precipitate, and dry it in an oven at 80°C for 12 h to obtain Bi / Bi 2 SiO 5 catalyst of light.

[0025] The pharmaceutical reagents used in the examples...

Embodiment 1

[0027] 1) 1.940 g Bi(NO 3 ) 3 5H 2 O and 0.5684 g Na 2 SiO 3 9H 2 O (2:1 molar ratio) was dissolved in 50 mL ethylene glycol and 50 mL deionized water, respectively, and stirred for 1 h to form solutions A and B. Take equal volumes of 20 mL solution A and 20 mL solution B, mix and stir for 2 h , forming a white suspension C;

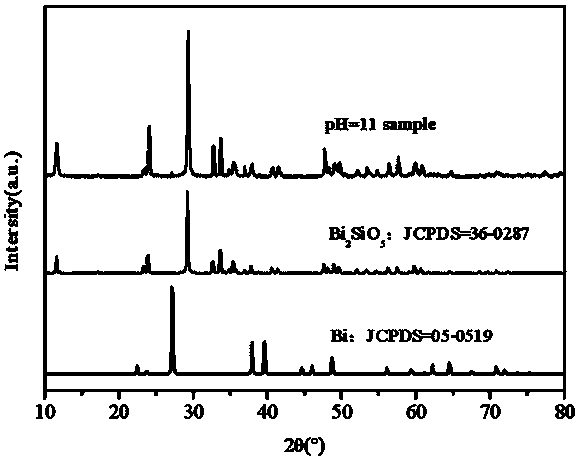

[0028] 2) Add 1 mol / L NaOH solution dropwise to the suspension C to adjust the pH of the solution to 11, transfer the reaction solution to a 100 mL reactor, react at 150°C for 6 h, take out the reactor and cool it to room temperature, After centrifugation, the precipitate was washed three times with deionized water and absolute ethanol, and then the precipitate was collected and dried in an oven at 80 °C for 12 h to obtain Bi / Bi 2 SiO 5 catalyst of light.

[0029] Bi / Bi prepared above 2 SiO 5 Photocatalyst for photoreduction of CO 2 Performance test, the selectivity of its gas phase product CO is 100%, photocatalytic reduction of CO under th...

Embodiment 2

[0031] 1) 2.910 g Bi(NO 3 ) 3 5H 2 O and 0.5684 g Na 2 SiO 3 9H 2 O (3:1 molar ratio) was dissolved in 100 mL ethylene glycol and 100 mL deionized water, stirred for 1 h to form solutions A and B, 50 mL of solution A and 50 mL of solution B were mixed and stirred for 2 h to form white suspension C;

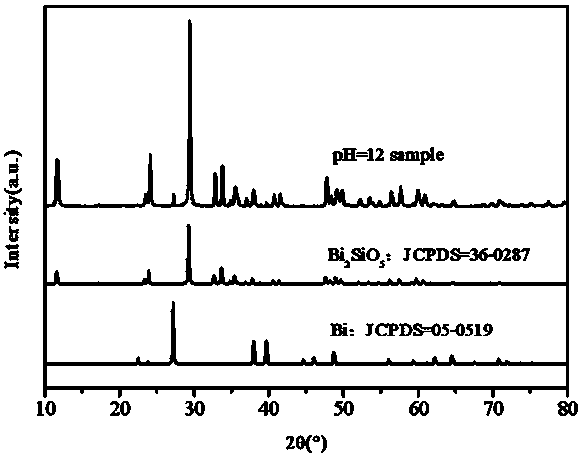

[0032] 2) Add 1 mol / L NaOH solution dropwise to Suspension C to adjust the pH of the solution to 12, transfer the reaction solution to a 200 mL reactor, react at 180°C for 8 h, take out the reactor and cool to room temperature, After centrifugation, the precipitate was washed three times with deionized water and absolute ethanol, and then the precipitate was collected and dried in an oven at 80 °C for 12 h to obtain Bi / Bi 2 SiO 5 catalyst of light.

[0033] Bi / Bi prepared above 2 SiO 5 Photocatalyst for photoreduction of CO 2 Performance test, the selectivity of its gas phase product CO is 100%, photocatalytic reduction of CO under the irradiation of ultraviolet light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com