A kind of modified chitosan inhibitor and its flotation separation method

A chitosan and inhibitor technology, applied in the field of molybdenum polymetallic sulfide mineral processing, can solve the problems of high toxicity of inorganic inhibitors, poor ore adaptability, poor inhibitory effect, etc., and achieve safe use, easy raw materials, and strong inhibitory power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

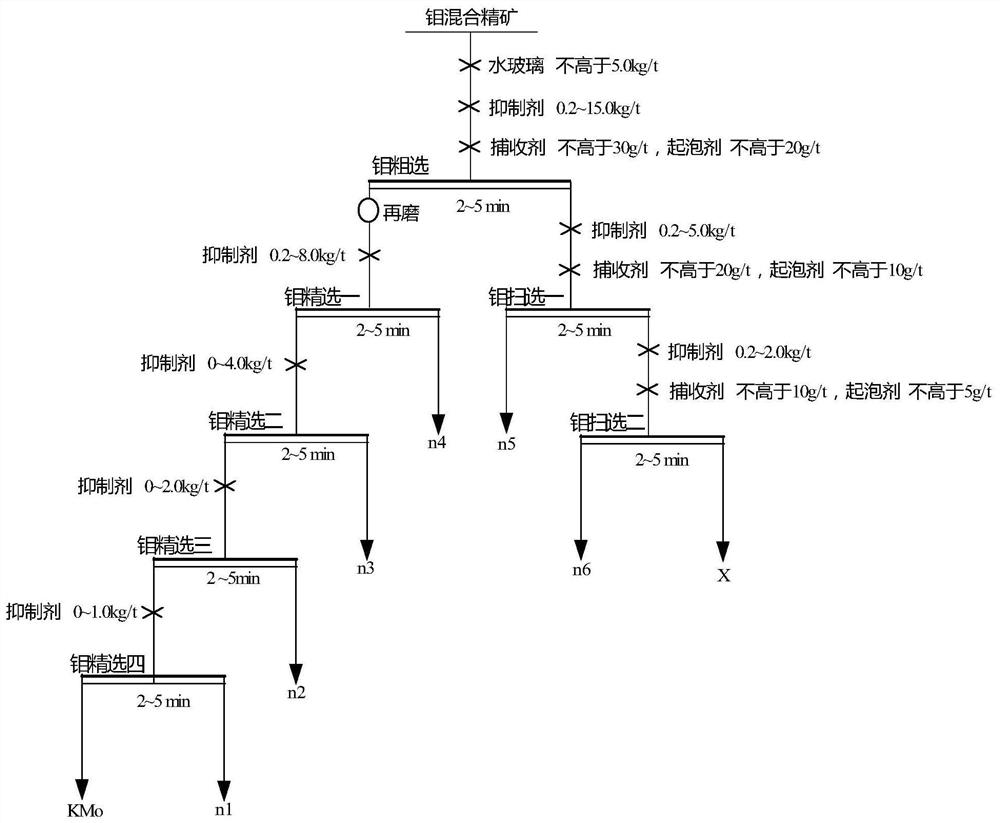

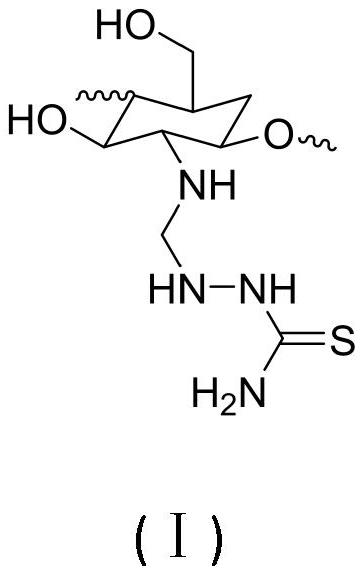

[0030] Embodiment 1 of the present invention discloses a kind of modified chitosan inhibitor and flotation separation method thereof, and the technical scheme adopted is as follows:

[0031] Add 20mL of acetic acid into a 250mL three-necked bottle, then add 150mL of water, stir well and add 8.0g of chitosan in batches, then stir at 30°C until the chitosan is completely dissolved, and the solution in the three-necked bottle is transparent at this time state. After about 30 minutes, add 4.5 g of thiosemicarbazide (equivalent to 0.5 times the molar weight of the pyran ring), and continue stirring until all the reactants are dissolved, at which point the bottle becomes transparent again. Stirring was continued for 1 h, 1 mL of formaldehyde with a concentration of 40% was added dropwise into the three-necked flask, and the reaction was continued for 10 h under sufficient stirring, and the pH was adjusted with acid and alkali until the bottle was a transparent solution to obtain a m...

Embodiment 2

[0034] Embodiment 2 of the present invention discloses a modified chitosan inhibitor and a flotation separation method thereof, and the technical scheme adopted is as follows:

[0035] The molybdenum-lead polymetallic sulfide ore is subjected to mixed flotation to obtain a copper-molybdenum mixed concentrate; the molybdenum grade of the molybdenum mixed concentrate is 9.44%, and the lead grade is 1.31%. Flotation of the molybdenum-lead mixed concentrate was carried out by adopting the process of first roughing, second sweeping and four refining in the above content, and the modified chitosan inhibitor prepared in Example 1 was used as the lead inhibitor to obtain the molybdenum concentrate. After experimentation: the grade of the molybdenum concentrate is 50.36%, the lead content is 0.058%, and the recovery rate of molybdenum is 46.66%.

Embodiment 3

[0037] Embodiment 3 of the present invention discloses a kind of flotation separation method of modified chitosan inhibitor, and the technical scheme adopted is as follows:

[0038]Utilize the modified chitosan inhibitor provided by the embodiment of the present invention 1 to carry out molybdenum-lead and copper-molybdenum pure mineral artificial mixed ore flotation separation test, when the inhibitor consumption is 10mg / L, molybdenum-lead and copper-molybdenum pure mineral artificial The mixed ore is well separated. At this time, the grade of molybdenum can reach more than 52.66%, and the copper and lead content are 2.58% and 1.76% respectively.

[0039] In summary, the embodiments of the present invention have the advantages of low toxicity, safe use, convenient addition, easy access to raw materials, etc., and have strong inhibitory power to chalcopyrite, galena, pyrite, bismuthite, etc. It can well achieve the purpose of reducing impurities in molybdenum concentrate, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com