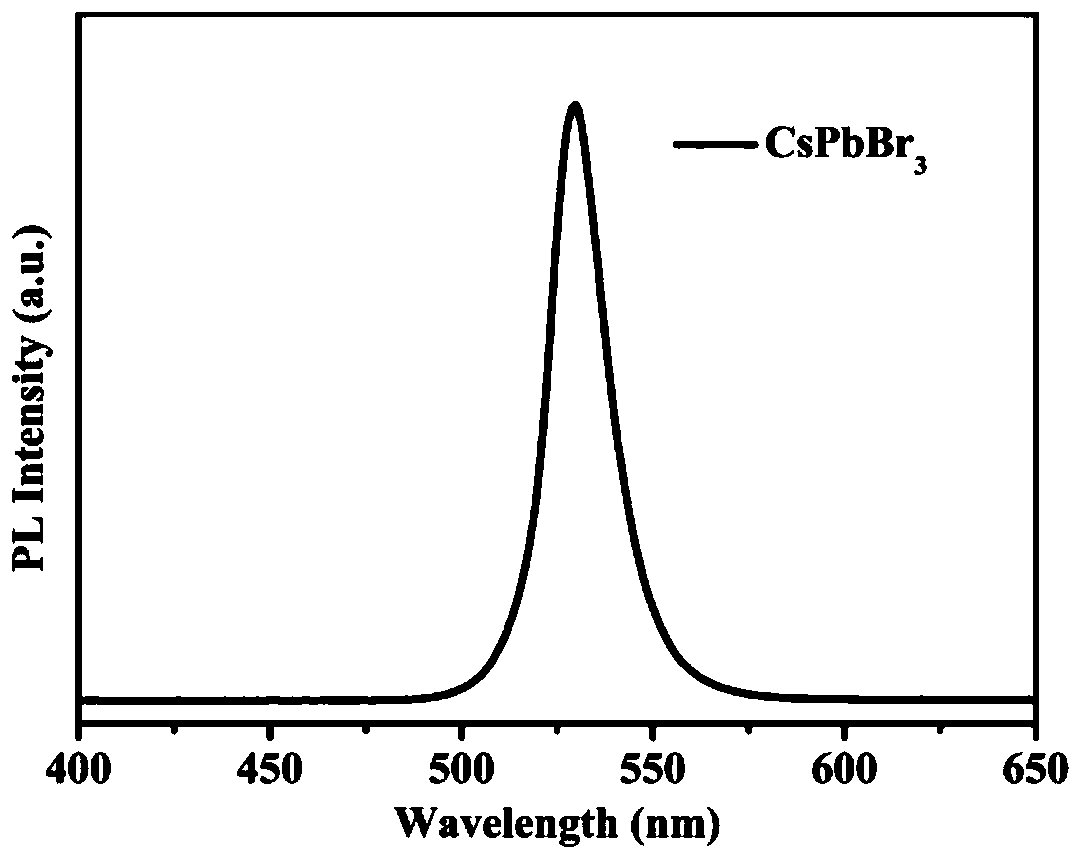

Hexagonal-phase CsPbBr3 nanocrystalline and preparation method thereof

A technology of nanocrystals and hexagonal phases, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of not being suitable for application and promotion, and not obtaining large-volume hexagonal nanosheets, so as to avoid self-absorption effect, Ease of operation and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

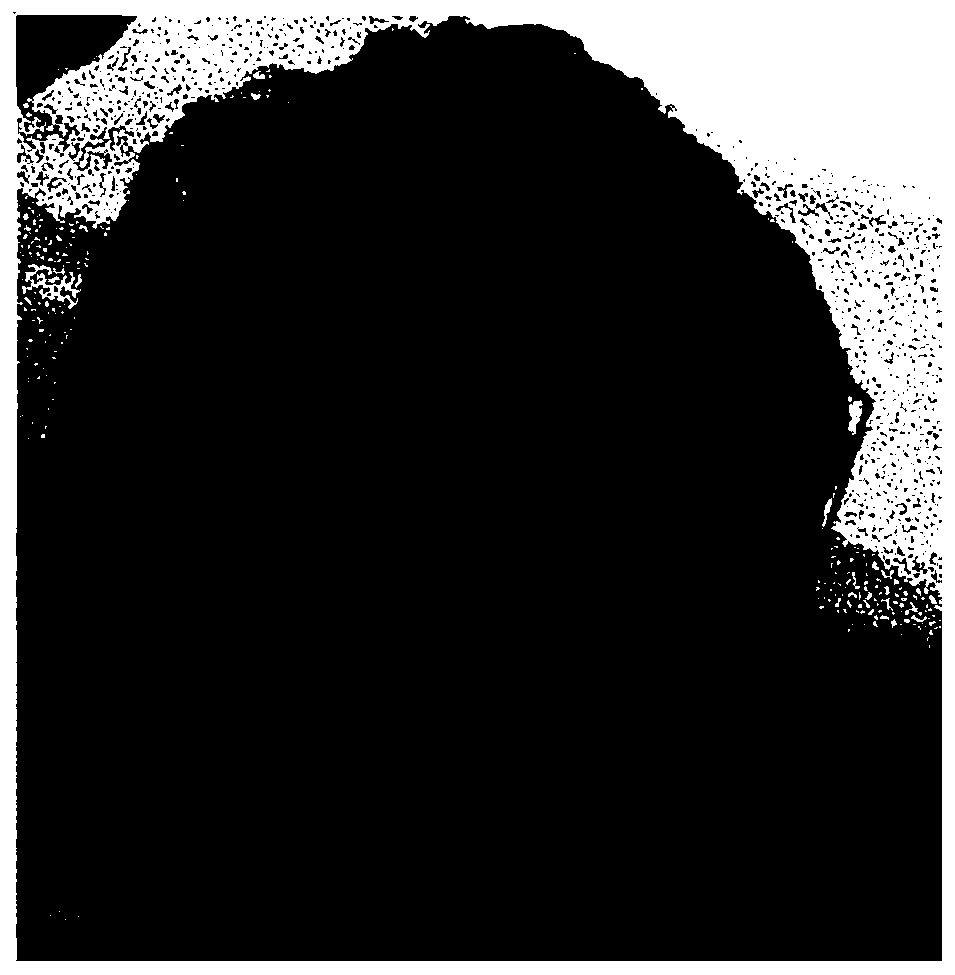

[0037] A hexagonal CsPbBr 3 A method for preparing nanocrystals, comprising the steps of:

[0038] (1) Preparation of lead bromide precursor solution: Measure 1ml of oleylamine and 0.5ml of oleic acid in 10ml of DMF respectively, take 100mg of lead bromide powder in 8ml of DMF solution, and sonicate for 10min to obtain a uniformly dispersed solution. Then placed in a 50°C water bath and stirred for 10 min to dissolve.

[0039] (2) Preparation of cesium bromide precursor solution: Measure 1ml oleylamine and 0.5ml oleic acid respectively in 10ml absolute ethanol, take 60mg cesium bromide powder and place it in 10ml absolute ethanol solution, ultrasonic 10min, get Disperse the solution evenly, then place it in a 60°C water bath and stir for 30 minutes to dissolve.

[0040](3) Take 0.8ml lead bromide precursor solution and cesium bromide precursor solution at the same time, quickly inject into 5ml chloroform solution, stir continuously at 1200rmp / min for 60s, and let stand for 5...

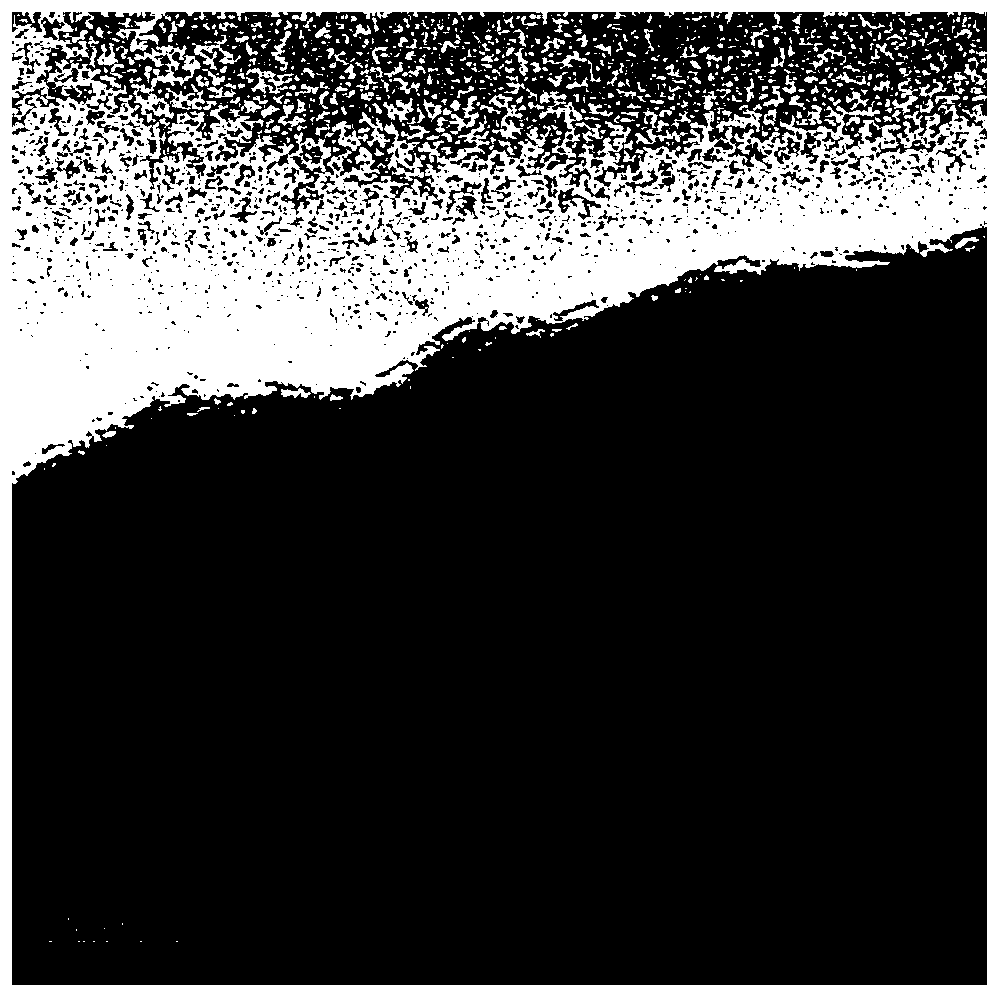

Embodiment 2

[0043] (1) Preparation of lead bromide precursor solution: Measure 1ml of oleylamine and 0.5ml of oleic acid in 12ml of DMF respectively, take 120mg of lead bromide powder in 12ml of DMF solution, and sonicate for 10min to obtain a uniformly dispersed solution , and then placed in a 60°C water bath and stirred for 20 minutes to dissolve.

[0044] (2) Preparation of cesium bromide precursor solution: measure 1ml oleylamine respectively, place 0.5ml oleic acid in 12ml dehydrated ethanol, get 80mg cesium bromide powder and place it in 12ml dehydrated ethanol solution, ultrasonic 10min, obtain Disperse the solution evenly, then place it in a 70°C water bath and stir for 45 minutes to dissolve.

[0045] (3) Take 1.0ml lead bromide precursor solution and cesium bromide precursor solution at the same time, quickly inject into 10ml chloroform solution, stir continuously at 800rmp / min for 60s, and let stand for 8 days. Finally, the product obtained by centrifugation at 6000rpm / min is ...

Embodiment 3

[0048] A hexagonal CsPbBr 3 A method for preparing nanocrystals, comprising the steps of:

[0049] (1) Preparation of lead bromide precursor solution: measure 1ml oleylamine and 0.5ml oleic acid respectively in 15ml DMF, take 140mg lead bromide powder and place it in 15ml DMF solution, ultrasonic 10min to obtain a uniformly dispersed solution , and then placed in a 70°C water bath and stirred for 30 minutes to dissolve.

[0050] (2) Preparation of cesium bromide precursor solution: measure 1ml oleylamine respectively, 0.5ml oleic acid is placed in 15ml absolute ethanol, take 85mg cesium bromide powder and place it in 15ml absolute ethanol solution, ultrasonic 10min, obtain Disperse the solution evenly, then place it in a 70°C water bath and stir for 60 minutes to dissolve.

[0051] (3) Take 1.2ml of lead bromide precursor solution and cesium bromide precursor solution at the same time, quickly inject into 10ml of chloroform solution, keep stirring for 60s, and let stand for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com