Strontium titanate-based dielectric ceramic with high energy storage density and preparation method thereof

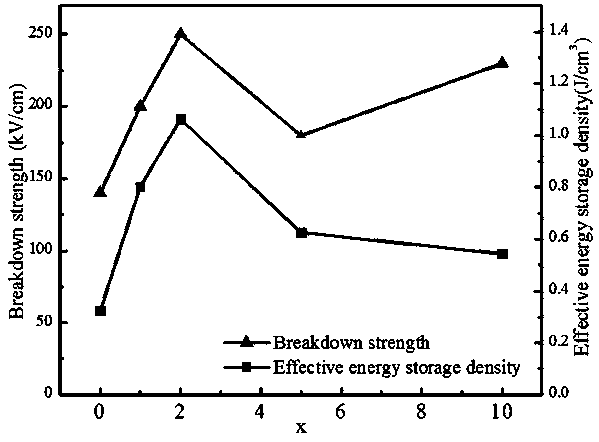

A technology of high energy storage density and dielectric ceramics, which is applied in the field of strontium titanate-based dielectric ceramics and its preparation, can solve the problems of high sintering temperature and low energy storage density, achieve enhanced breakdown electric field, increase energy storage density, and improve The effect of density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A strontium titanate-based dielectric ceramic with high energy storage density of the present invention has the advantages of high energy storage density and low sintering temperature, and its preparation method comprises the following steps:

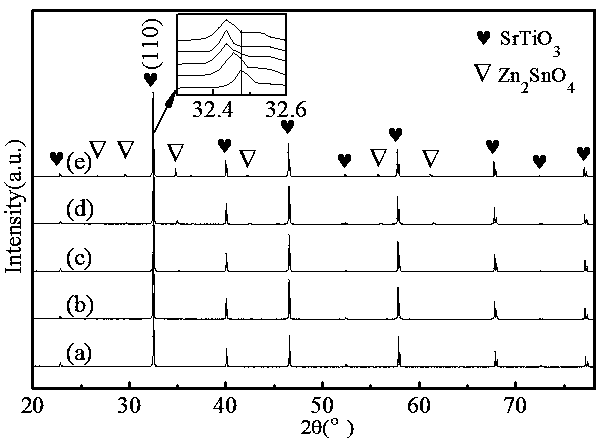

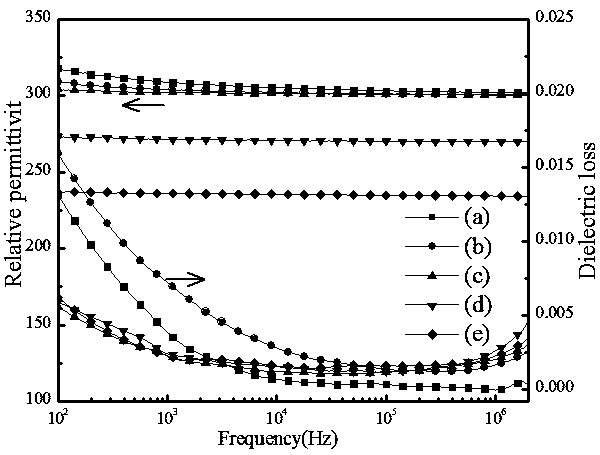

[0036] Step 1: First, according to the stoichiometric ratio of SrTiO 3 : Zn 2 SnO 4 =1: x% converted to SrTiO 3 Powder and Zn 2 SnO 4 The quality of the powder, weigh the SrTiO according to the calculated quality 3 Powder and Zn 2 SnO 4 Powder, the weighed powder is fully ball milled with absolute ethanol as a dispersant. The ball mill used for ball milling is made of nylon, and the medium ball inside is made of zirconia. The three diameters are 5mm, 6.5mm and The 11mm dielectric ball is configured according to the mass ratio of 3:5:2. The purity of the absolute ethanol used in ball milling is 99.7% analytically pure; the amount of absolute ethanol added is added according to the ratio of 1.2ml of absolute ethanol per gra...

Embodiment 1

[0048] A method for preparing strontium titanate-based dielectric ceramics with high energy storage density, comprising the following steps:

[0049] Step 1. Weigh 14.9121g of SrCO according to the stoichiometric ratio of 1:1 3 and 8.0687 g of TiO 2 For chemical raw materials, pour the prepared raw materials into a ball mill jar, and add 28ml of absolute ethanol. Ball milled in a ball mill for 12 hours, and then dried in a blast oven at 90°C. Grind the dried raw materials into powder. Take an appropriate amount of ground powder and place it in a mold, and press it into a green body under a pressure of 358 MPa. The green body was heated to 1100 °C at a rate of 3 °C / min, and kept for 2 hours to synthesize SrTiO 3 . When the furnace temperature was naturally cooled to room temperature, the sample was taken out and ground to obtain SrTiO 3 Powder.

[0050] Step 2. Weigh 15.1467g of SnO according to the stoichiometric ratio of 1:2 2 and 16.4424g of ZnO chemical raw material...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is: step 3, according to the stoichiometric ratio of SrTiO 3 : Zn 2 SnO 4 =1:0.02 Weigh the SrTiO prepared in step 1 and step 2 respectively 3 Powder 22.7510g and Zn 2 SnO 4 Powder 0.62692g. The preparation and production process of all the other raw materials are the same as in Example 1. Finally get SrTiO 3 +0.02molZn 2 SnO 4 Composite ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com