A kind of preparation method of the modified starch ether that improves the sliding performance of tile adhesive

A starch ether and tile adhesive technology, applied in the direction of starch-derived adhesives, adhesive types, adhesive additives, etc., can solve the problems of cumbersome operation and unfavorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

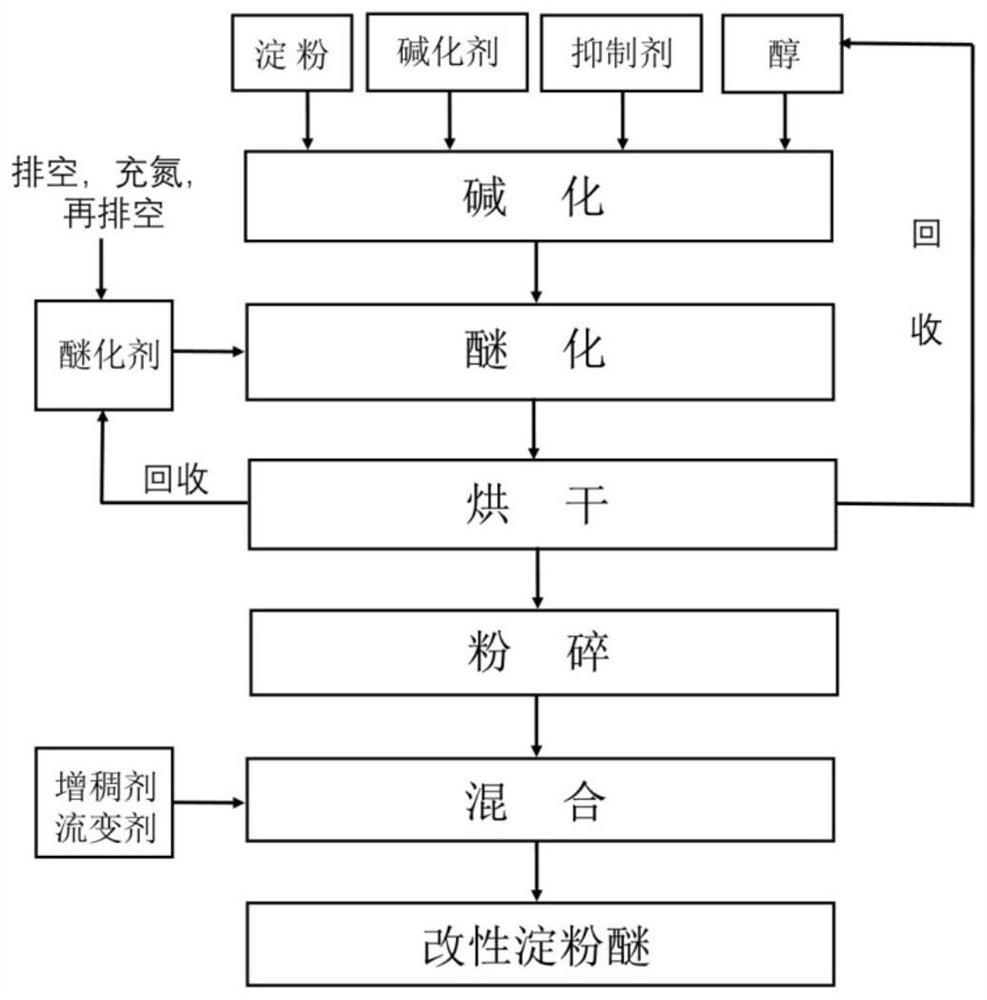

[0064] A kind of preparation method of the modified starch ether that promotes tile adhesive sliding performance, comprises the following operation steps:

[0065] (1) chemical modification: starch is etherified, dried and pulverized;

[0066] Add tapioca starch, alkalizing agent NaOH, ethanol and inhibitor Na 2 SO 4 , the reactor was evacuated and purged with nitrogen to remove oxygen, evacuated again, and then etherification agents were added to the reactor: chloroacetic acid, propylene oxide and ethylene oxide, reacted at 20 ° C for 1.5 hours, and the temperature was raised to 40 React at ℃ for 2.5 hours, and at 60℃ for 4 hours. After the reaction is completed, dry and recover ethanol, and pulverize;

[0067] The mass ratio of above-mentioned tapioca starch, sodium hydroxide, chloroacetic acid, propylene oxide and ethylene oxide is=1:0.09:0.10:0.12:0.02;

[0068] The tapioca starch and inhibitor Na 2 SO 4 The mass ratio is 1:0.05;

[0069] The mass ratio of described ...

Embodiment 2

[0088] A kind of preparation method of the modified starch ether that promotes tile adhesive sliding performance, comprises the following operation steps:

[0089] (1) prepare another kind of starch ether of the present invention according to the description of embodiment 1 step (1), the difference is that the etherification agent is chloroacetic acid and propylene oxide, starch, sodium hydroxide, chloroacetic acid and cyclic The mass ratio of oxypropane is = 1:0.09:0.10:0.12, and the reaction temperature of etherification is 40°C for 3 hours and 60°C for 5 hours;

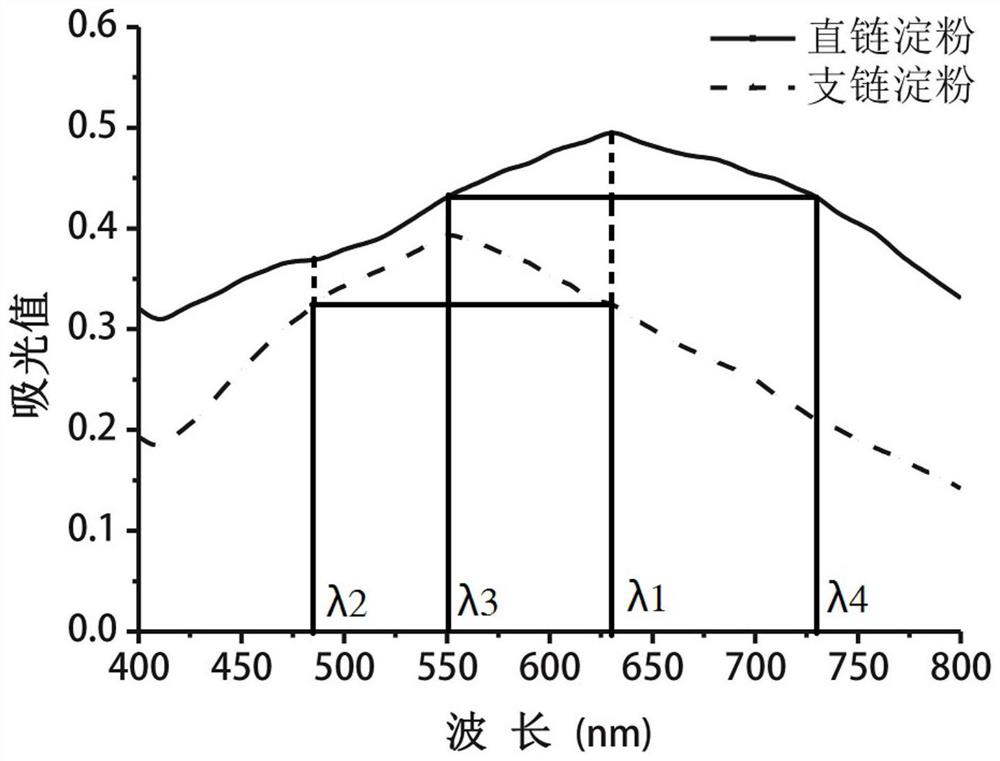

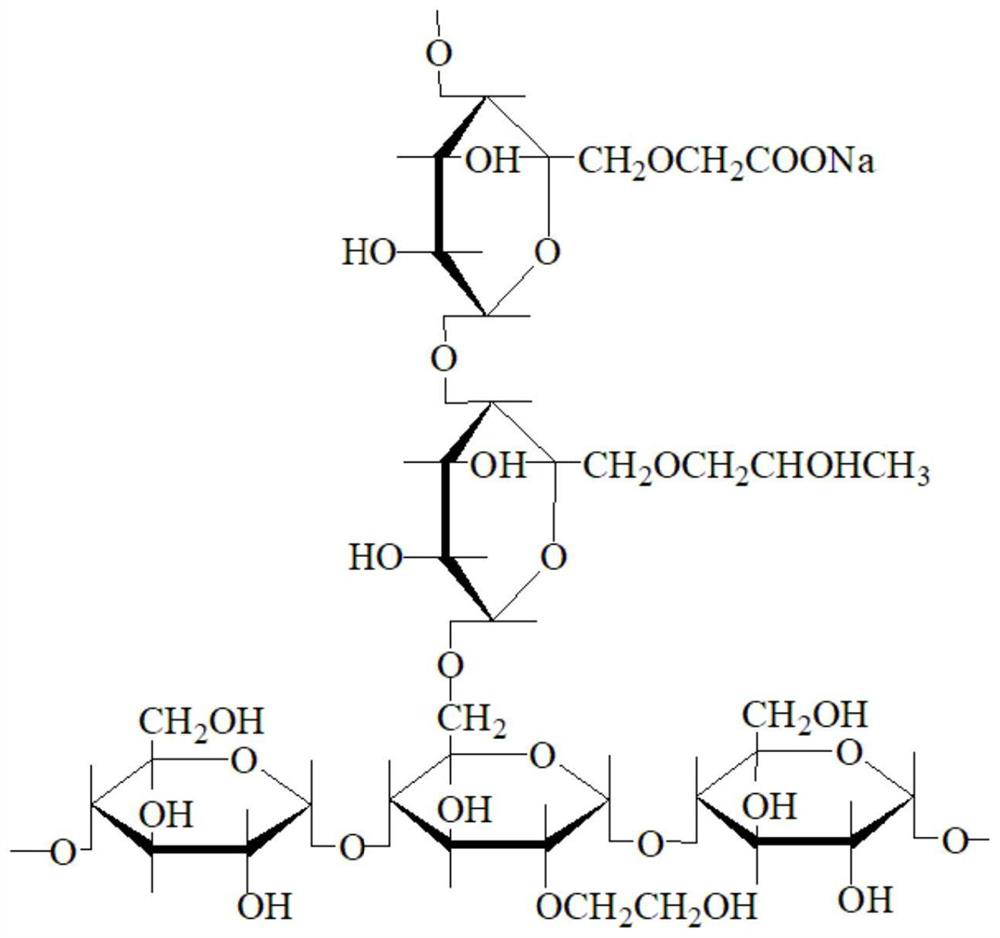

[0090] The amylose content of the raw starch is 17.23%, the amylopectin content is 68.78%, and the total starch content is 86.01%. The obtained carboxymethyl hydroxypropyl starch structure diagram is shown in Figure 4 , wherein the carboxymethyl substitution degree is 0.16, the hydroxypropoxy content is 12.6%, the 5% viscosity is 7000cp, and the ash content is 16%;

[0091] (2) Physical modification: mix the pre...

Embodiment 3

[0110] A kind of preparation method of the modified starch ether that promotes tile adhesive sliding performance, comprises the following operation steps:

[0111] (1) prepare another kind of starch ether of the present invention according to the description of embodiment 1 step (1), the difference is that the etherifying agent is propylene oxide and ethylene oxide, starch, sodium hydroxide, epoxy The mass ratio of propane to ethylene oxide is =1:0.02:0.12:0.05, and the etherification reaction temperature is 2.5 hours at 20°C, 2.5 hours at 40°C, and 4 hours at 60°C;

[0112] The amylose content of the raw starch is 17.16%, the amylopectin content is 68.73%, and the total starch content is 85.89%. The structure diagram of the prepared hydroxypropyl hydroxyethyl starch is shown in Figure 5 , marked as 1# hydroxypropyl hydroxyethyl starch, wherein the hydroxypropoxy content is 12.5%, the hydroxyethoxy content is 6.5%, the 5% viscosity is 7000cp, and the ash content is 8%;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com