Bacterial strain for removing formaldehyde, formaldehyde scavenger and preparation method thereof

A formaldehyde scavenger and formaldehyde-removing technology, applied in the field of formaldehyde scavenger and its preparation, formaldehyde-removing bacterial strains, can solve the problems of poor formaldehyde removal effect, achieve excellent removal effect and strong formaldehyde degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of formaldehyde scavenger, comprising the following steps:

[0031] (1) activate the above-mentioned bacterial strain for removing formaldehyde, and then place the activated bacterial strain in a microbial culture medium containing formaldehyde to cultivate;

[0032] (2) Centrifuge the obtained bacterial suspension, remove the supernatant and resuspend the obtained bacterial liquid, then nitrogen freeze the obtained bacterial liquid, grind and rupture the nitrogen frozen bacterial liquid, and then Resuspension and centrifugation are carried out, and the supernatant obtained by centrifugation is mixed with trehalose, organic silicon and ferric sulfate to obtain the formaldehyde scavenger.

[0033] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0034] The bacterial strain used for removing formaldehyde of the present application has the characteristic of extremely strong ability to degrade formal...

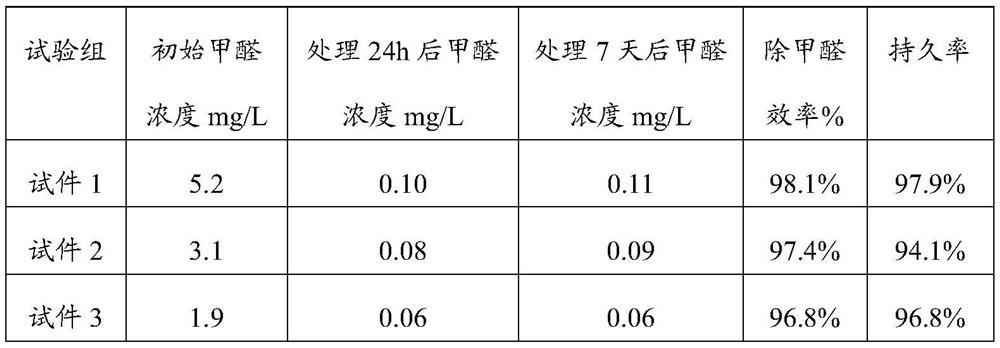

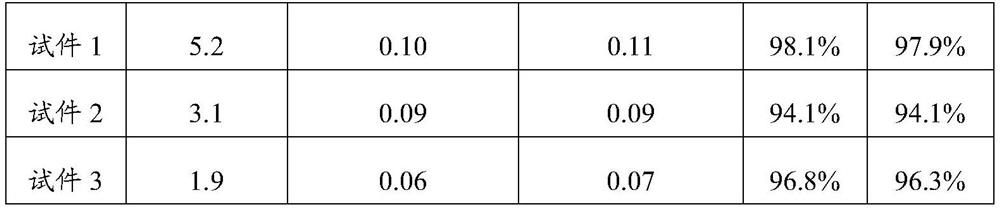

Embodiment 1

[0041] The preparation method of the formaldehyde scavenger of the present embodiment may further comprise the steps:

[0042] (1) The mutagenesis of Bacillus subtilis was carried out using a normal temperature and pressure plasma mutagenesis machine (ARTP), and the formaldehyde culture solution with different concentrations was used as a screening. After diluting the bacterial suspension 100 times, draw 10ul drops on the ARTP circular receiving piece under aseptic conditions and spread evenly, and then place the receiving piece under the radiation emitter. Using helium as the working gas, instrument parameters: helium gas flow rate 10L / min, input power 120W, mutagenesis time set to 30s, 60s, 90s, 120s, 150s, 180s, 240s. Place the treated samples in EP tubes containing 1ml of normal saline, shake them on a vortex shaker for 2 minutes, so that the bacteria fall off the slide, and inoculate 100ul of them in beef extract peptone medium containing 100mg / L formaldehyde Perform sha...

Embodiment 2

[0047] The preparation method of the formaldehyde scavenger of the present embodiment may further comprise the steps:

[0048] (1) The mutagenesis of Bacillus subtilis was carried out using a normal temperature and pressure plasma mutagenesis machine (ARTP), and the formaldehyde culture solution with different concentrations was used as a screening. After diluting the bacterial suspension 100 times, draw 10ul drops on the ARTP circular receiving piece under aseptic conditions and spread evenly, and then place the receiving piece under the radiation emitter. Using helium as the working gas, instrument parameters: helium gas flow rate 10L / min, input power 120W, mutagenesis time set to 30s, 60s, 90s, 120s, 150s, 180s, 240s. Place the treated samples in EP tubes containing 1ml of normal saline, shake them on a vortex shaker for 2 minutes, so that the bacteria fall off the slide, and inoculate 100ul of them in beef extract peptone medium containing 100mg / L formaldehyde Perform sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com