Culture method of burkholderia multivorans strain and applications of burkholderia multivorans in catalyzing synthesis of baijiu flavor esters and degradation of baijiu harmful esters

A technology that phagocytizes Burkholderia and catalyzes esters, applied in the field of microorganisms, can solve the problems of slow ester production, low synthesis efficiency, low yield of high-quality wine, etc., and achieve high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

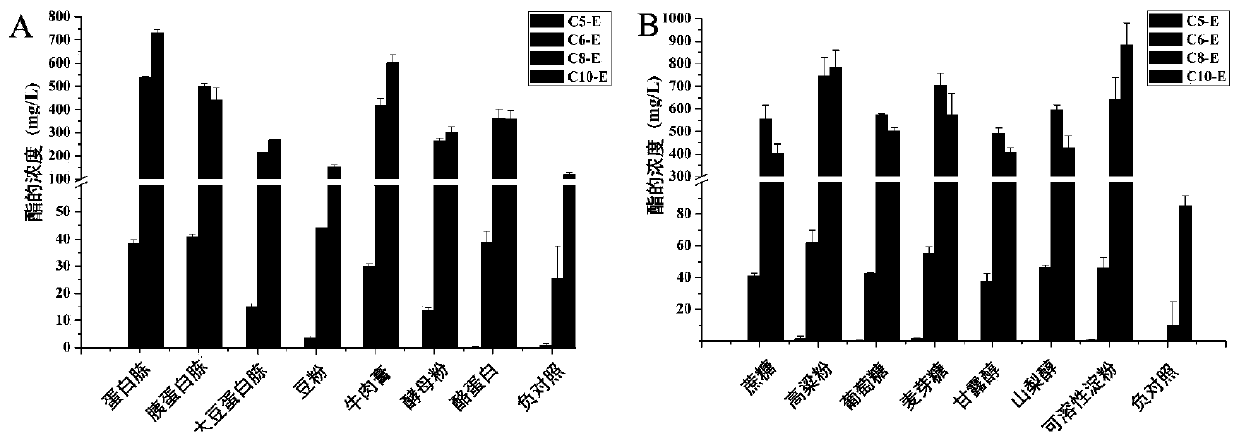

[0026] Example 1 Nitrogen source and carbon source optimization of Burkholderia polyphage CGMCC 1.3829 fermentation culture

[0027] This example is carried out in order to optimize the cultivation method of Burkholderia polyphage CGMCC 1.3829 to obtain better liquor flavor esters.

[0028] 1. Strain activation: Under aseptic conditions, inoculate Burkholderia polyphage CGMCC 1.3829 into a 30mL test tube containing 5mL fermentation medium, and culture on a shaker at 30±2°C, 150±50r / min for 1 -2 days.

[0029] 2. Nitrogen source optimization fermentation culture: Under aseptic conditions, inoculate activated Burkholderia polyphagocytida CGMCC1.3829 into a 300mL Erlenmeyer flask containing 100mL fermentation medium, shaker at 30±2°C, 150± 50r / min, cultivate for 2–5 days. The fermented liquid after cultivating is prepared crude enzyme liquid according to embodiment 2 (1st point), and gained crude enzyme liquid carries out the mensuration of ester synthesis according to embodime...

Embodiment 2

[0033] Example 2 Preparation of Burkholderia polyphage CGMCC 1.3829 Crude Enzyme Preparation and Catalytic Ester Synthesis under Conditions of Simulated Liquor Fermentation Water Phase System

[0034] Based on the culture solution obtained in Example 1, the following experiments were carried out.

[0035] 1. Preparation of crude enzyme preparation:

[0036] Take 10-30 mL of the fermentation medium in a 50 mL centrifuge tube, break up the bacterial cells with an ultrasonic cell disruptor, centrifuge at 6000×g for 10 min, and take the supernatant as a crude enzyme preparation.

[0037] 2. Catalyzing ester synthesis under the condition of simulated liquor fermentation water phase system

[0038] The 10mL reaction system is as follows: Burkholderia polyphagia CGMCC 1.3829 crude enzyme solution, 1mL; citric acid buffer (pH 4.0), 9mL (add ethanol to 1M); caproic acid, caprylic acid and capric acid, the final concentration 10mM. 30±1°C, 150±10r / min water bath shaker reaction for 1...

Embodiment 3

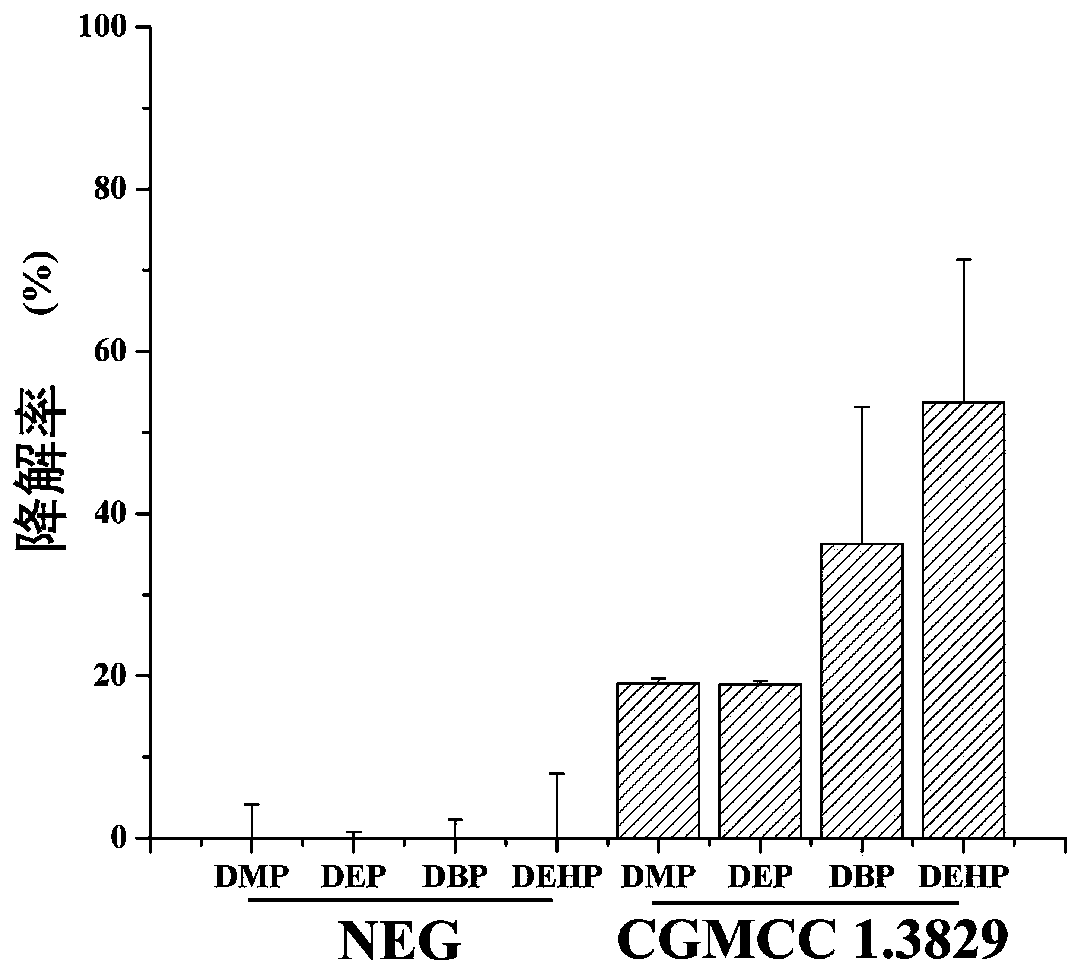

[0044] Example 3 Degradation of Burkholderia polyphage CGMCC 1.3829 to DMP, DEP, DBP and DEHP

[0045] In the experiment, it was found that Burkholderia polyphage CGMCC 1.3829 has the property of degrading some harmful esters, so this property was further verified based on the following culture method. The composition of the medium includes: yeast powder 5.0 g / L, (NH 4 ) 2 SO 4 2.0g / L, MgSO 4 ·7H 2 O 0.2g / L, CaCl 2 2H 2 O 0.01g / L, FeSO 4 ·7H 2 O 0.001g / L, Na 2 HPO 4 12H 2 O 1.5g / L, KH 2 PO 4 1.5g / L, sterilized at 115°C for 20min, and added DMP, DEP, DBP and DEHP with a final concentration of 200mg / L. Put 10mL of medium into a 100mL Erlenmeyer flask, and inoculate 1–3%. The culture conditions are: 30±2°C, 150±50r / min, culture for 3-7 days.

[0046] After culturing, transfer 10 mL of fermentation broth into a 50 mL centrifuge tube, add 2 mL of n-hexane, shake and mix vigorously for 30 seconds, centrifuge, take the supernatant, filter and centrifuge for quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com