Improved silicon-based negative electrode material for lithium ion battery

A technology of silicon-based negative electrode materials and lithium-ion batteries, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as poor stability, poor electrical conductivity, and limited energy density of lithium-ion batteries, achieving high stability, The effect of high capacity retention rate and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

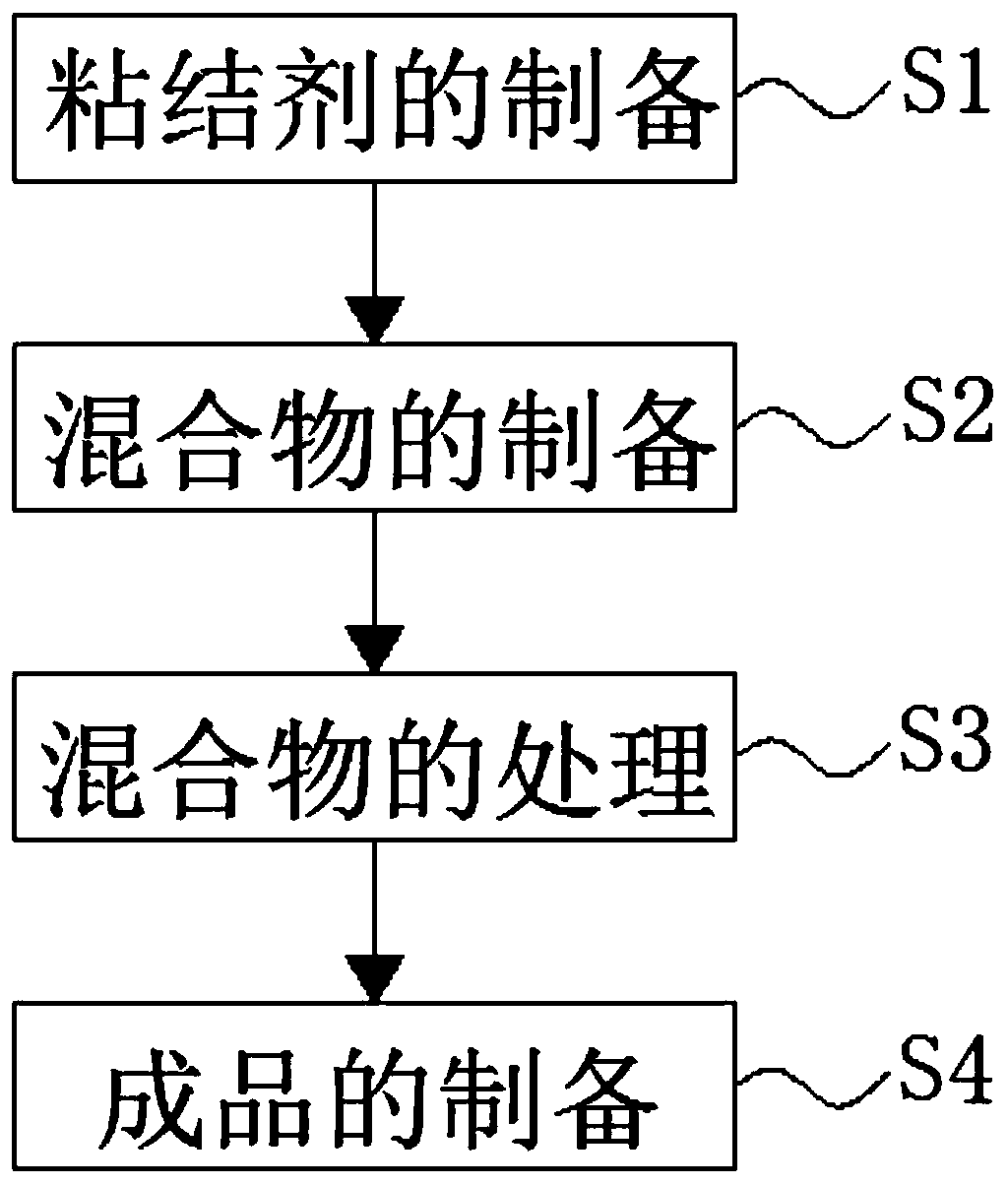

[0036] S1, preparation of binder: select 45 parts of gellan gum, and pour the gellan gum evenly into 29 parts of cold sodium hydroxide solution, use a stirring device to stir for 35 minutes, raise the temperature of the stirring device to room temperature, select 25 parts of chloroacetic acid and 30 parts of solvent, pour 25 parts of chloroacetic acid into 30 parts of solvent, stir to make 25 parts of chloroacetic acid dissolve in 30 parts of solvent to form a mixed solution, and slowly add the mixed solution three times to the previous The mixture was reacted at room temperature for 4.5 hours, and after rinsing with 25 parts of solvent for several times, the crude product was obtained. Finally, the crude product was dissolved in 10 parts of solvent, filtered to remove impurities, then dialyzed, and freeze-dried to obtain a binder;

[0037] S2, preparation of the mixture: select 65 parts of silicon nanowires, 30 parts of silicon dioxide and 30 parts of graphite, and pour the se...

Embodiment 2

[0041] S1. Preparation of binder: select 25 parts of gellan gum, and pour 25 parts of gellan gum evenly into 22 parts of cold sodium hydroxide solution, stir with a mixer for 30 minutes, and raise the temperature of the stirring device to room temperature , select 20 parts of chloroacetic acid and 25 parts of solvent, pour 20 parts of chloroacetic acid into 25 parts of solvent, stir slowly to make 20 parts of chloroacetic acid melt in 25 parts of solvent to form a mixed solution, and slowly drop the mixed solution three times Added to the previous mixture, reacted at room temperature for 4 hours, after washing with 25 parts of solvent for several times, the crude product was obtained, and finally the crude product was dissolved in 10 parts of solvent, filtered to remove impurities, then dialyzed and freeze-dried to obtain binder;

[0042] S2, preparation of the mixture: select 50 parts of silicon nanowires, 20 parts of silicon dioxide and 15 parts of graphite, and pour the sel...

Embodiment 3

[0046] S1. Preparation of binder: select 55 parts of gellan gum, and pour 55 parts of gellan gum evenly into 35 parts of cold sodium hydroxide solution, stir with a mixer for 30 minutes, and raise the temperature of the stirring device to room temperature , select 30 parts of chloroacetic acid and 40 parts of solvent, pour 30 parts of chloroacetic acid into 40 parts of solvent, stir slowly to make 30 parts of chloroacetic acid melt in 40 parts of solvent to form a mixed solution, and slowly drop the mixed solution three times Added to the previous mixture, reacted at room temperature for 5 hours, after washing with 20 parts of solvent for several times, the crude product was obtained, and finally the crude product was dissolved in 10 parts of solvent, filtered to remove impurities, then dialyzed and freeze-dried to obtain binder;

[0047] S2, preparation of the mixture: select 80 parts of silicon nanowires, 40 parts of silicon dioxide and 45 parts of graphite, and pour the sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com