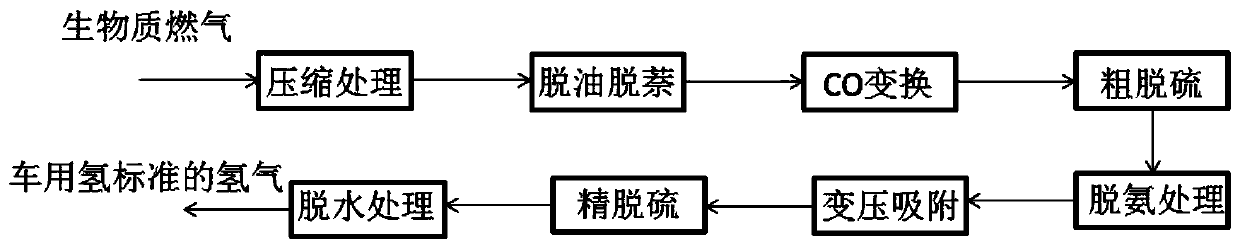

Method for preparing hydrogen satisfying automotive hydrogen standard from biomass gas

A biomass gas and hydrogen technology, applied in chemical instruments and methods, using solid contact hydrogen separation, hydrogen, etc., can solve the problem of not being able to obtain hydrogen that satisfies hydrogen fuel cells, and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0094] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0096] Biomass gas is provided by Gaoyou Linyuan Technology Development Co., Ltd., and its composition (vol%, dry basis) is shown in the table below.

[0097] components H 2

CO CO 2

N 2

CH 4

cHm O 2

total content 14.8 37.4 15.4 15.9 14.4 1.30 0.80 100

[0098] Flow: 4500Nm 3 / h;

[0099] Pressure: ~4KPaG;

[0100] Temperature: 40°C;

[0101] The impurity content is as follows:

[0102] components h 2 S

NH 3

naphthalene tar and dust mg / Nm 3

~200 ~135 ~100 ~10

[0103] This embodiment provides a method for preparing hydrogen meeting the vehicle hydrogen standard from biomass gas, and the specific process is as follows:

[0104] A reciprocating compressor will be used to pressurize the biomass gas to 1.2MPa; during the pressurization process, a large amount of organic components in the biomass gas can be compressed to remove some impurities such as tar and naphthalene to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com