Temperature-sensitive-type terahertz detector based on phase change material and preparation method

A technology of terahertz detectors and phase change materials, which is applied in the field of terahertz photodetectors to achieve high sensitivity response, simple manufacturing process, and increase the effect of sensing ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

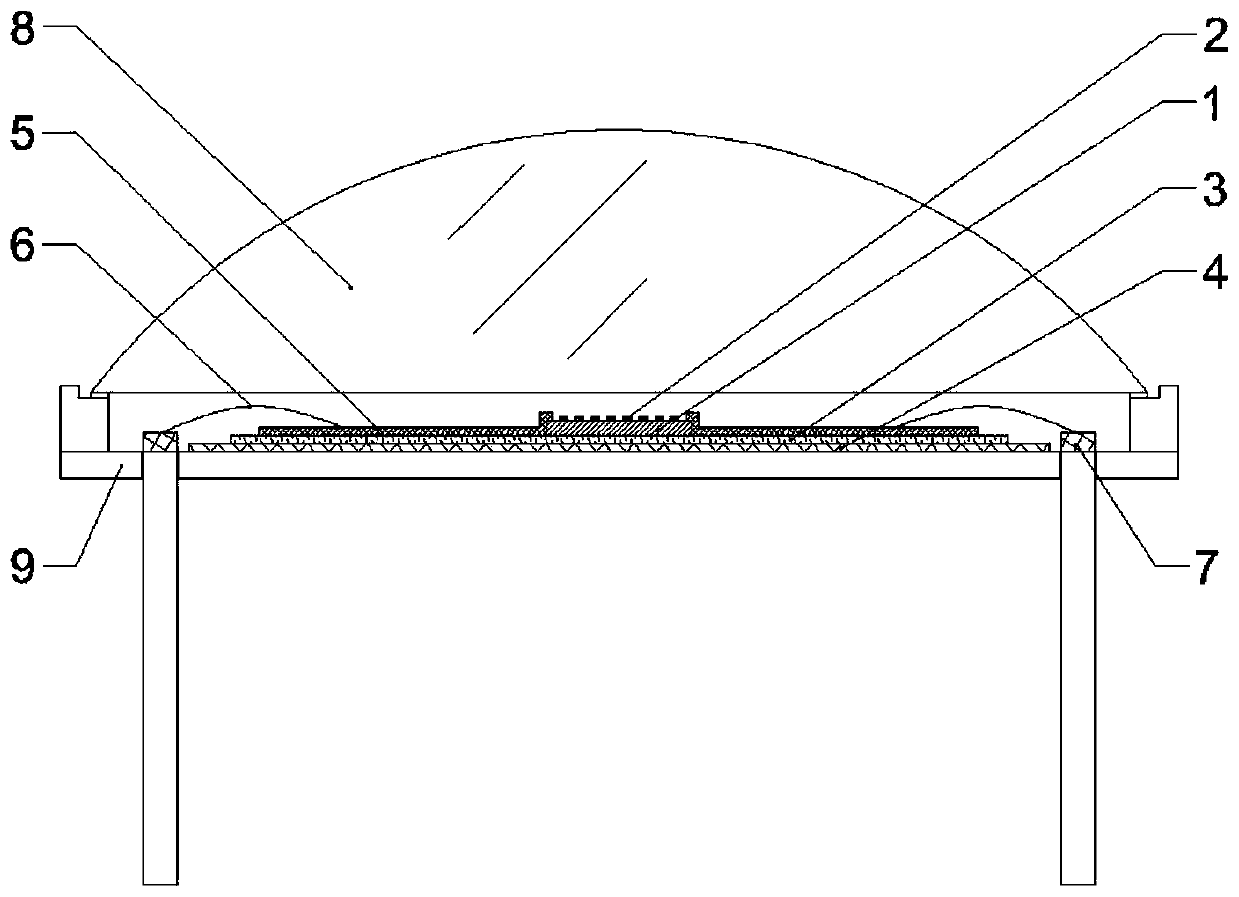

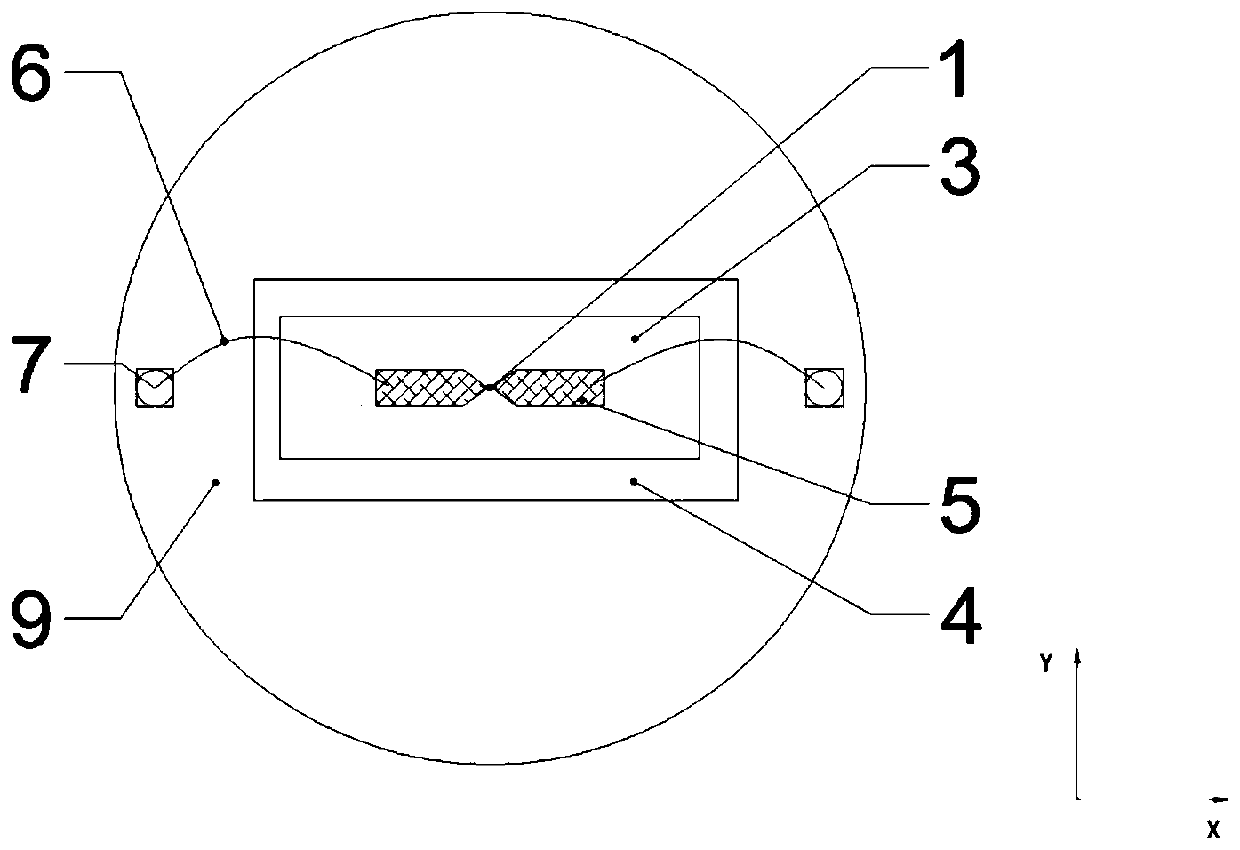

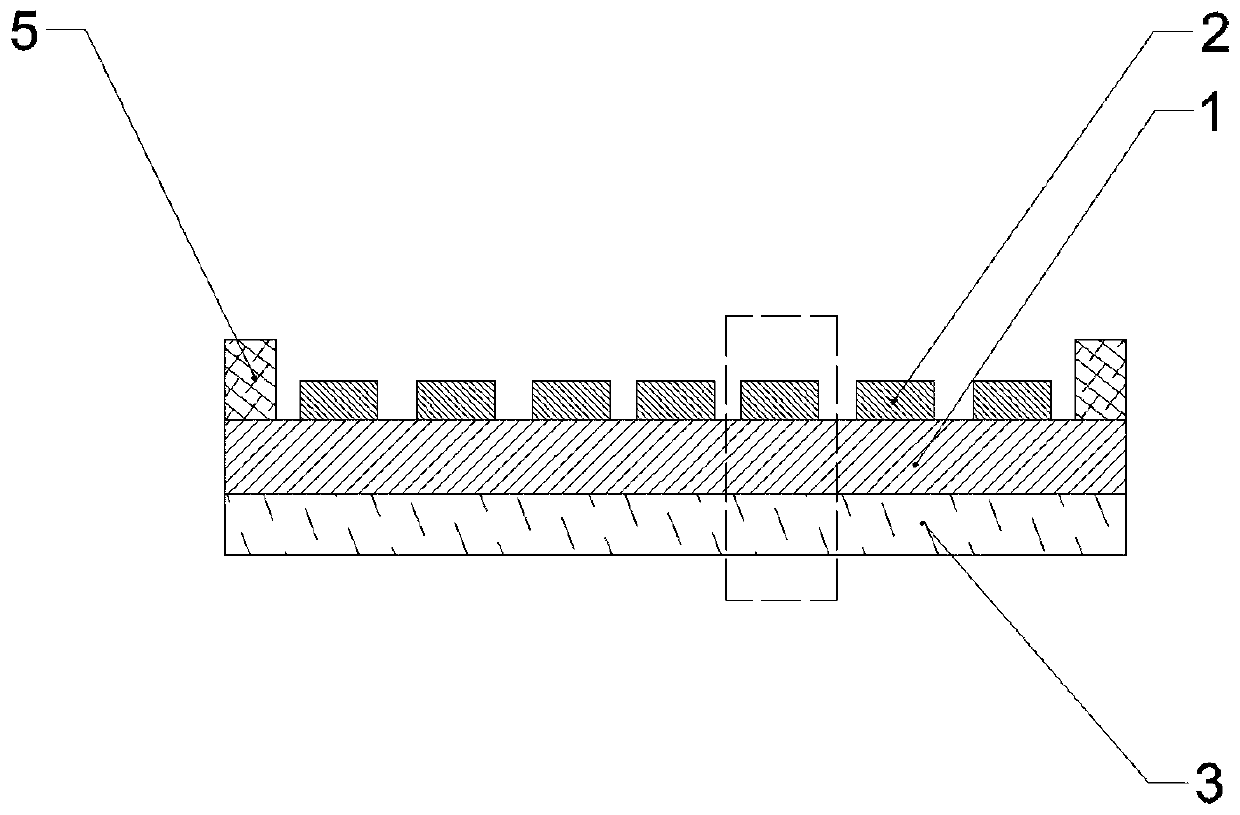

[0032]1. Select (111) crystal direction undoped single throw indium antimonide single crystal material, use epoxy resin glue to paste the single throw surface of the indium antimonide material sample on the amorphous alumina substrate 3, mechanically thin, The thickness of the indium antimonide single crystal is reduced to 10 microns. The photoresist AZ 4330 is selected, and the photolithography pattern is obtained after the photolithography process such as uniform layer exposure, development, and post-baking. Wet etching is carried out first, and an etching solution is prepared according to the ratio of HF: HAC: H2O2 = 1:1:1 to obtain an indium antimonide mesa with an etching depth of about 8um. Dry etching is then performed to remove the remaining 2um indium antimonide material layer. So far, an indium antimonide sensitive cell 1 mesa with a thickness of 10 um and a size of 90 um×20 um (length×width) has been obtained. Clean the sample sheet again with acetone, alcohol, an...

Embodiment 2

[0038] 1. Select (111) crystal direction undoped single throw indium antimonide single crystal material, use epoxy resin glue to paste the single throw surface of the indium antimonide material sample on the amorphous alumina substrate 3, mechanically thin, The thickness of the indium antimonide single crystal is reduced to 10 microns. The photoresist AZ 4330 is selected, and the photolithography pattern is obtained after the photolithography process such as uniform layer exposure, development, and post-baking. Wet etching is carried out first, and an etching solution is prepared according to the ratio of HF: HAC: H2O2 = 1:1:1 to obtain an indium antimonide mesa with an etching depth of about 8um. Dry etching is then performed to remove the remaining 2um indium antimonide material layer. So far, the indium antimonide sensitive element 1 mesa with a thickness of 10 um and a size of 120 um×20 um (length×width) has been obtained. Clean the sample sheet again with acetone, alcoh...

Embodiment 3

[0044] 1. Select (111) crystal direction undoped single throw indium antimonide single crystal material, use epoxy resin glue to paste the single throw surface of the indium antimonide material sample on the amorphous alumina substrate 3, mechanically thin, The thickness of the indium antimonide single crystal is reduced to 10 microns. The photoresist AZ 4330 is selected, and the photolithography pattern is obtained after the photolithography process such as uniform layer exposure, development, and post-baking. Wet etching is carried out first, and an etching solution is prepared according to the ratio of HF: HAC: H2O2 = 1:1:1 to obtain an indium antimonide mesa with an etching depth of about 8um. Dry etching is then performed to remove the remaining 2um indium antimonide material layer. So far, an indium antimonide sensitive cell 1 mesa with a thickness of 10 um and a size of 140 um×20 um (length×width) has been obtained. Clean the sample sheet again with acetone, alcohol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com