Lithium hexafluorozirconate and carbon co-coated lithium iron phosphate composite material, and preparation method and application thereof

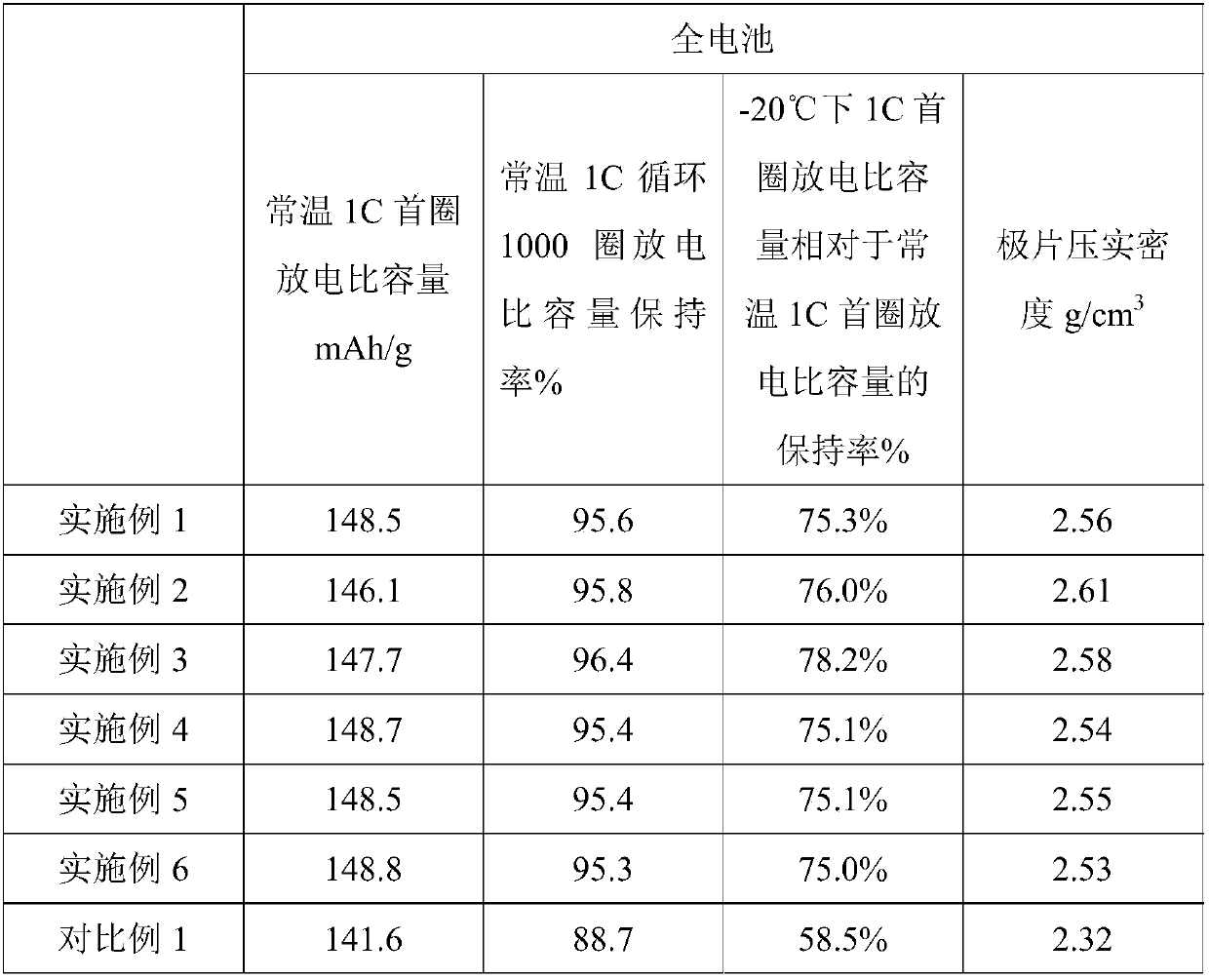

A technology of carbon co-coating lithium iron phosphate and lithium hexafluorozirconate, which is applied to electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as poor electrochemical performance, low first-cycle capacity, and poor low-temperature performance , to achieve the effect of increasing compaction density, reducing loss and increasing the capacity of the first circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

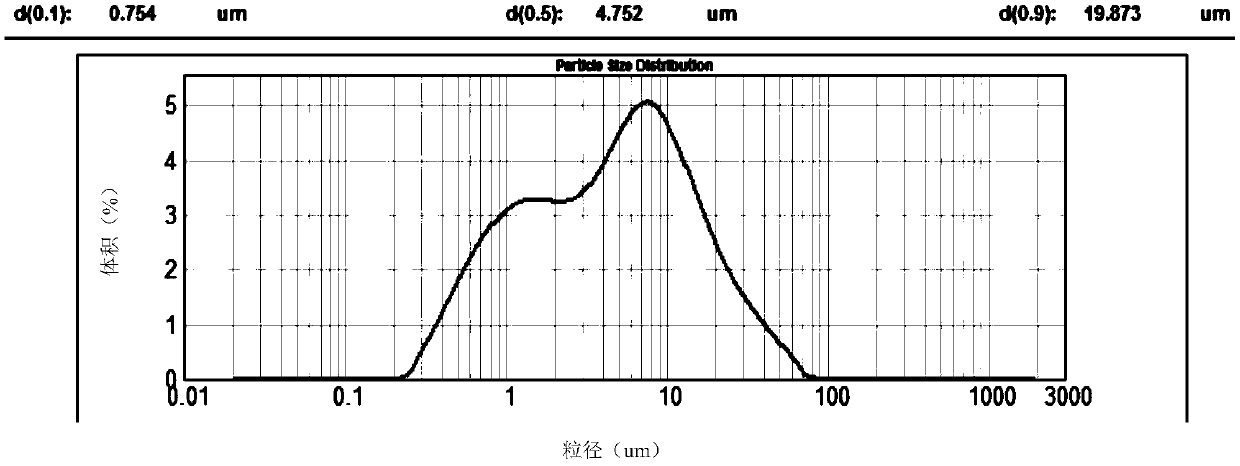

[0074] Lithium carbonate, anhydrous ferric phosphate, glucose and lithium hexafluorozirconate are put into the grinding tank in sequence according to the molar ratio Li:Fe:C:Zr=1.05:1:1:0.001, and deionized water is added to the slurry The solid content of the material is 25%, and the precursor slurry is fully ground to a particle size of 100nm to realize activation.

[0075]The resulting slurry was spray-dried in a spray dryer, and the inlet temperature and outlet temperature were set to 310°C and 120°C respectively; 4 fluid nozzles were used for spraying, flow meters were installed on the two inlet pipes, and flow meters were installed on the two inlet pipes. A peristaltic pump is installed on the pipe and fed from the same bucket of slurry. The intake volume of one of the intake pipes is 30NL / min, and the feed volume of the corresponding feed pipe is 5ml / min, which is used to prepare small particle size particles; the intake volume of the other intake pipe is 90NL / min; The...

Embodiment 2

[0080] Lithium hydroxide, ferric phosphate dihydrate, polyvinyl alcohol and lithium hexafluorozirconate are put into the grinding tank in sequence according to the molar ratio of Li:Fe:C:Zr=1.01:1:1.4:0.1, and pure water is added to The solid content of the slurry is 15%, and the precursor slurry is fully ground to a particle size of 300nm to realize activation.

[0081] The resulting slurry was spray-dried in a spray dryer, and the inlet temperature and outlet temperature were set to 280°C and 120°C respectively; 8 fluid nozzles were used for spraying, flow meters were installed on 4 inlet pipes, and flow meters were installed on 4 inlet pipes. A peristaltic pump is installed on the pipe and fed from the same bucket of slurry. The intake volume of one of the intake pipes is 10NL / min, and the feed volume of the corresponding feed pipe is 5ml / min, which is used to prepare small particle size particles; the intake volume of the other three intake pipes is 60NL / min. min; the fee...

Embodiment 3

[0084] Lithium acetate, ammonium ferric phosphate dihydrate, phytic acid and lithium hexafluorozirconate are put into the grinding tank in sequence according to the molar ratio of Li:Fe:C:Zr=1.03:1:1.4:0.005, and pure water is added to The solid content of the slurry is 40%, and the precursor slurry is fully ground to a particle size of 400 nm.

[0085] The resulting slurry was spray-dried in a spray dryer, and the inlet temperature and outlet temperature were set to 300°C and 120°C respectively; 6 fluid nozzles were used for spraying, flow meters were installed on 3 inlet pipes, and flowmeters were installed on 3 inlet pipes. A peristaltic pump is installed on the pipe and fed from the same bucket of slurry. The intake volume of one of the intake pipes is 10NL / min, and the feed volume of the corresponding feed pipe is 2ml / min, which is used to prepare small particle size particles; the intake volume of the other two intake pipes is 70NL / min. min; the feeding volume of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com