Method for producing diaminobenzene compound

A kind of technology of diaminobenzene and compound is applied in the field of diaminobenzene compound to achieve the effects of improving yield, promoting dissolution and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

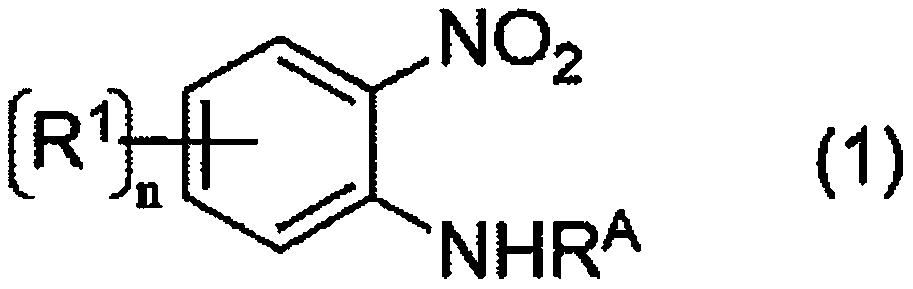

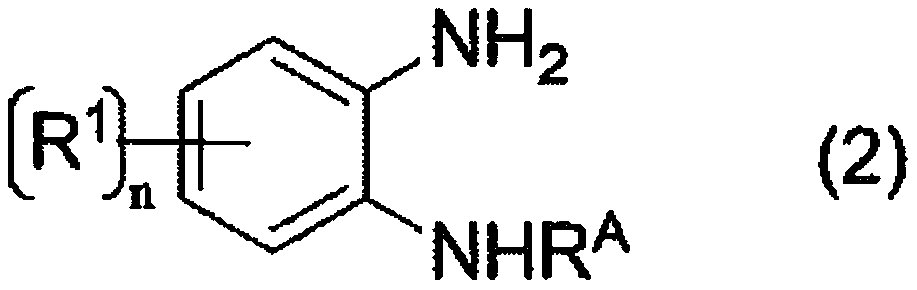

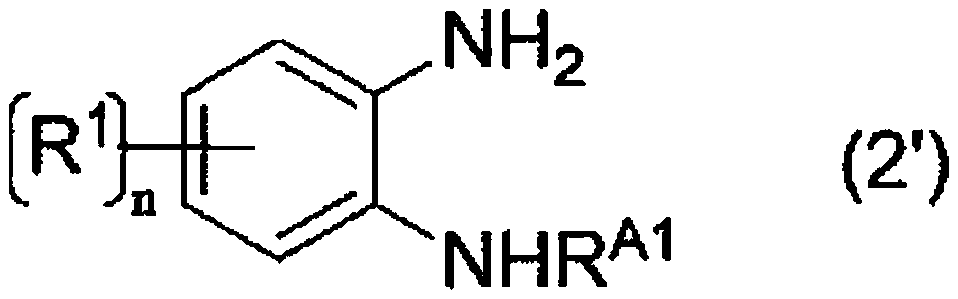

[0183] Example 1 (Example of producing diaminobenzene compound using aminonitrobenzene compound)

[0184] The reaction of the following formula is carried out.

[0185]

[0186] Methyl 2-amino-3-nitrobenzoate (1.0 g, 5.1mmol; 2-amino-3-nitrobenzene compound), sodium dithionite (purity 80% by mass) (3.33g, 15.3mmol ((the molar number of sodium dithionite calculated from the purity); Wako Pure Chemicals Produced by the company, alkali metal dithionite), potassium carbonate (1.4g, 10.2mmol; alkali metal carbonate) were stirred and mixed at a reaction temperature of 100°C for 4 hours (reaction time).

[0187]Water (14 mL) was added to the obtained reaction liquid, and then, a mixed liquid of the obtained reaction liquid and water was extracted with ethyl acetate (5 mL). The extraction based on this ethyl acetate (5 ml) was repeated 5 times. After washing this ethyl acetate solution (total 25ml), by concentrating under reduced pressure, obtain target product 2,3-diaminobenzoi...

Embodiment 2

[0190] Example 2 (Example of producing diaminobenzene compound using aminonitrobenzene compound)

[0191] With respect to embodiment 1, except using sodium dithionite (purity 80% by mass) (2.22g, 10.2mmol ((the molar number of sodium dithionite calculated from purity); Wako Pure Chemical Company produces, the alkali of dithionite Metal salt), except that the reaction time was 5 hours, others carried out the same operation as Example 1. The conversion rate was 10%. Polar impurities were not confirmed.

Embodiment 3

[0192] Example 3 (Example of producing diaminobenzene compound using aminonitrobenzene compound)

[0193] With respect to Example 1, except that the reaction solvent was a mixed solvent of DMF (7ml) and water (0.099ml, 5.1mmol), the same operation was performed as in Example 1. The yield of methyl 2,3-diaminobenzoate was 94%. The conversion rate was 100%. In addition, the purity of methyl 2,3-diaminobenzoate confirmed by HPLC was 95.4%, and the polar impurities were 2.5%. The analytical results of the obtained methyl 2,3-diaminobenzoate were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com