Recycling method of waste from factory production of hypsizigus marmoreus

A technology for the production of waste materials and shimeji mushrooms, which is applied in the preparation of organic fertilizers, botanical equipment and methods, applications, etc., can solve the problems of burning seedlings, waste, and unsuitability for direct fermentation, so as to improve conversion efficiency, avoid waste, Avoid the effects of burning seedlings and difficult control of pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

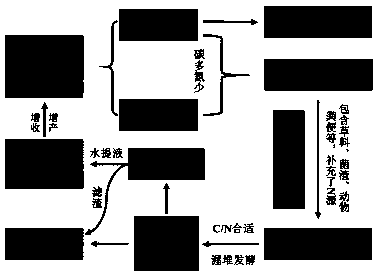

Method used

Image

Examples

Embodiment 1

[0034] The specific operation process is as follows:

[0035] (1) Dried the discarded stipe and discarded mushroom body (hereinafter collectively referred to as the stem) at 60°C, then pulverized and passed through a 0.5mm sieve.

[0036](2) Weigh 500g of dry mushroom stalk powder, add 7.5L of water to stir according to the ratio of 1g of mushroom powder / 15mL of water, soak overnight, put the mixture into ultrasonic extraction equipment, extract at 60°C for 60 minutes; filter the sample liquid to remove macromolecules protein.

[0037] (3) Concentrate the filtrate to a volume of 800 mL with a multi-stage concentrator at a temperature of 95°C and a flow rate of 80 mL / min, and filter to discard the precipitate.

[0038] (4) Add 95% ethanol to the concentrated solution until the final concentration of ethanol is 80%, and let it stand overnight at 4°C; filter again, spray dry or dry it in a solar oven, and the product is the crude polysaccharide of shijiji mushroom, jijiji mushro...

Embodiment 2

[0042] Using mushroom handles to produce sea cucumber feed and supplementary cattle feed, the specific operation process is as follows:

[0043] (1) Dried the discarded stipe and discarded mushroom body (hereinafter collectively referred to as the stem) at 60°C, then pulverized and passed through a 0.5mm sieve. The sieved coarse powder is used as a biological source additive, and is added to cattle feed at a mass ratio of 0%-5%. The fine powder after sieving enters the following steps;

[0044] (2) Weigh 1000g of dried mushroom stalk powder, add 15L of water and stir according to the ratio of 1g of mushroom powder / 15mL of water, divide into 1L glass containers, soak overnight, put the mixture into ultrasonic extraction equipment, and extract at 60°C for 60 minutes.

[0045] (3) Filtrate the extract, take the filtrate, and use a multi-stage concentrator to concentrate the volume to 1600mL under the conditions of a temperature of 95°C and an inflow rate of 80 mL / min, and filter...

Embodiment 3

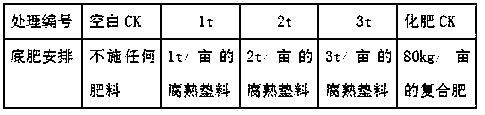

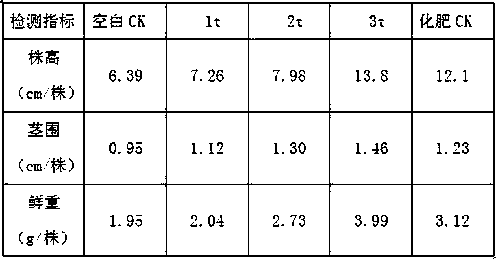

[0048] Use the bio-organic fertilizer made from waste litter, and add 0.1% EM bacteria powder by mass fraction.

[0049] The preparation process is as follows:

[0050] (1) Mushroom residues are non-polluting residues discarded after industrial production and leftovers discarded after packaging, with a water content of 45%-55%, naturally dried for 4 days, regularly turned over, and controlled to keep the water content below 20%. The measured moisture content is 15%, discard the moldy material, and the rest is used as bedding for cows; the moldy material is discarded directly during the drying process or used as a follow-up pile of decomposed raw materials, and the dried fungus residue is spread in the cow pen for 2-4cm. Yes, or in the excrement collection area, add shimeji mushroom residue, the ratio of the residue to feces is 1:0.7-4; the above method can effectively control the sewage, air odor, and pests and diseases in the breeding area.

[0051] (2) Add dry fungus residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com