Hollow biomass granular fuel forming machine

A technology of biomass pellets and molding machines, which is applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of slow fuel combustion speed, insufficient oxygen supply, slow heating, etc., achieve fast combustion speed, reduce maintenance and replacement of parts time, non-discrete effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

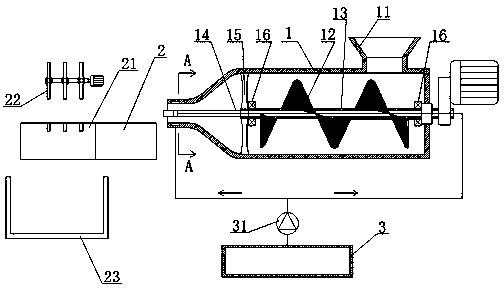

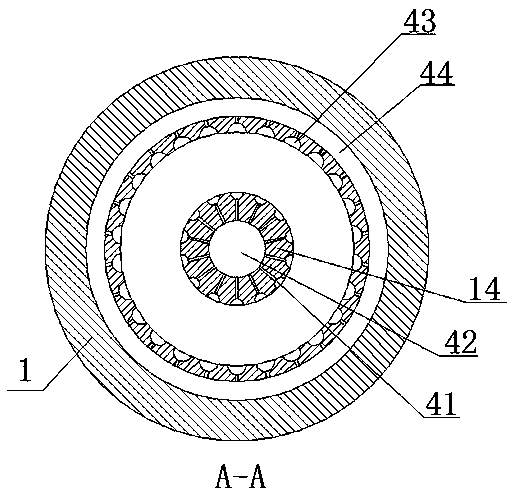

[0025] A hollow biomass particle fuel molding machine, comprising a casing 1, a feed inlet 11 is arranged above the casing 1, a hollow shaft 13 is installed on the inner axis of the casing 1, a screw pusher blade 12 is fixed on the outer periphery of the hollow shaft 13, and bearings at both ends of the hollow shaft 13 16, respectively fixed on the bracket 15 at the rear end of the housing and the front of the housing; the outlet end of the housing 1 is provided with a core rod 14, the fixed end of the core rod 14 is connected to the bracket 15, and the free end extends to the forming outlet;

[0026] The outlet end of the shell 1 is provided with a discharge platform 2, a discharge platform 21 is provided beside the discharge platform 2, and a cutting device 22 is provided above the discharge platform 21;

[0027] The upper plane of the unloading platform 21 is an inclined plane, and the collecting box 23 is placed under the unloading platform 21;

[0028] The core rod 14 is ...

Embodiment 2

[0034] The difference from Example 1 is that there are 12 core rods in the hollow biomass particle fuel molding machine, and a hole die corresponding to the position is set at the outlet for molding the outer circular surface of the biomass fuel. Hold white mineral oil.

Embodiment 3

[0036] The difference from Example 1 is that multiple hollow biomass pellet fuel molding machines are placed in parallel to operate simultaneously, and they share one adhesive box 3 and pump 31; 3-4 hollow biomass pellet fuel molding machines share one cutting device 22 and A collection box 23; the adhesive box 3 is filled with starch adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com