Preparation method of balance-axle bracket casting

A technology for balance shaft brackets and castings, which is applied in the field of preparation of balance shaft bracket castings, and can solve problems such as high scrap rate, difficult casting, and shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a balance shaft bracket casting, comprising the following steps:

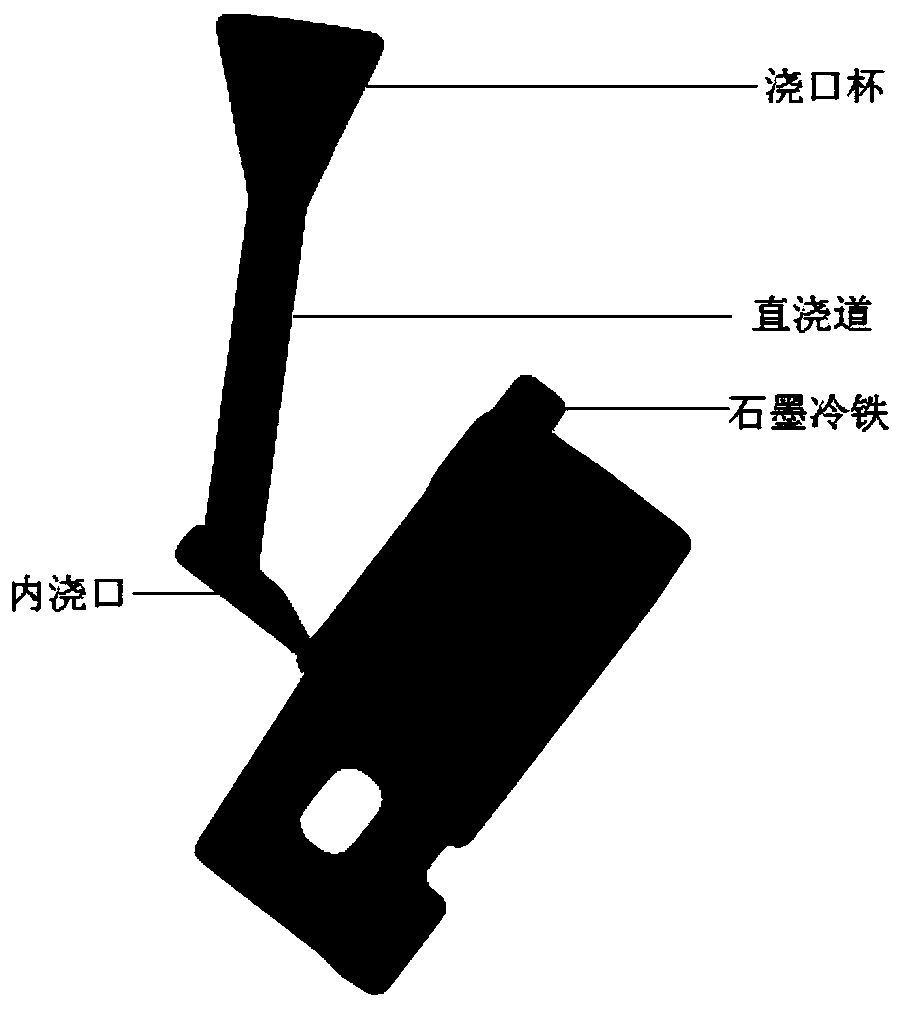

[0040] (1) Arrangement of the gating system: a one-to-one structure is adopted, and an ingate is provided at the end face of the shaft hole of the balance shaft connection part of the balance shaft support model, the ingate is connected with the sprue, and the ingate is connected with the sprue. A sprue cup is arranged on the top of the runner, a graphite cold iron installation position is arranged in the middle of the upper frame connection part of the balance shaft support model, and slag discharge risers are respectively arranged at both ends of the upper frame connection part;

[0041] Brush paint on the surface of the balance shaft bracket model to obtain a yellow mold;

[0042] The coating of the prone to defect position of the yellow mold is peeled off to obtain the position to be treated, after the hot melt adhesive is applied to the surface of the gr...

Embodiment 1

[0078] (1) The layout of the pouring system: a one-piece structure is adopted, and an ingate is provided at the end face of the shaft hole of the balance shaft connection part of the balance shaft support model. The ingate of the balance shaft support model is connected with a direct pouring There is a sprue cup on the top of the sprue; a cold iron installation position is set in the middle of the frame connection part on each balance shaft support model, and slag discharge risers are respectively set at both ends.

[0079] 1) White mold bonding: the specific operation steps are as follows

[0080] The white mold is polished to obtain the polished white mold, and the sandpaper used for grinding is 800#, and the grinding can make flashes, burrs and bumps on the white mold be polished off.

[0081] Apply WPH cold glue on the parts to be bonded of the polished white mold (use a brush to brush several times until the thickness is uniform and no accumulation phenomenon), and then c...

Embodiment 2

[0099] (1) The layout of the pouring system: a one-piece structure is adopted, and an ingate is provided at the end face of the shaft hole of the balance shaft connection part of the balance shaft support model. The ingate of the balance shaft support model is connected with a direct pouring There is a sprue cup on the top of the sprue; a cold iron installation position is set in the middle of the frame connection part on each balance shaft support model, and slag discharge risers are respectively set at both ends.

[0100] 1) White mold bonding: the specific operation steps are as follows

[0101] The white mold is polished to obtain the polished white mold, and the sandpaper used for grinding is 600#, and the grinding can make flashes, burrs and bumps on the white mold be polished off.

[0102] Apply WPH cold glue on the parts to be bonded of the polished white mold (use a brush to brush several times until the thickness is uniform and no accumulation phenomenon), and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimensions | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com