Titanium or titanium alloy spherical powder with rare earth oxide distributed on the surface and preparation method thereof

A rare earth oxide, spherical powder technology, applied in the field of metal powder materials, achieves the effects of low preparation cost, high composition uniformity, and increased pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

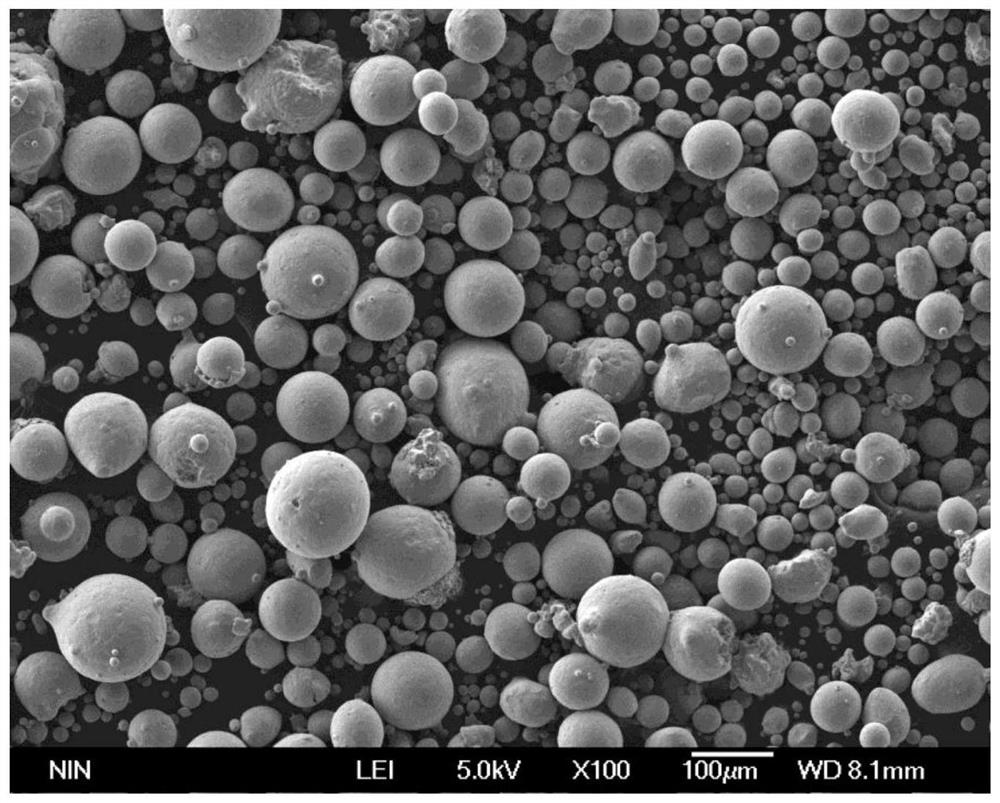

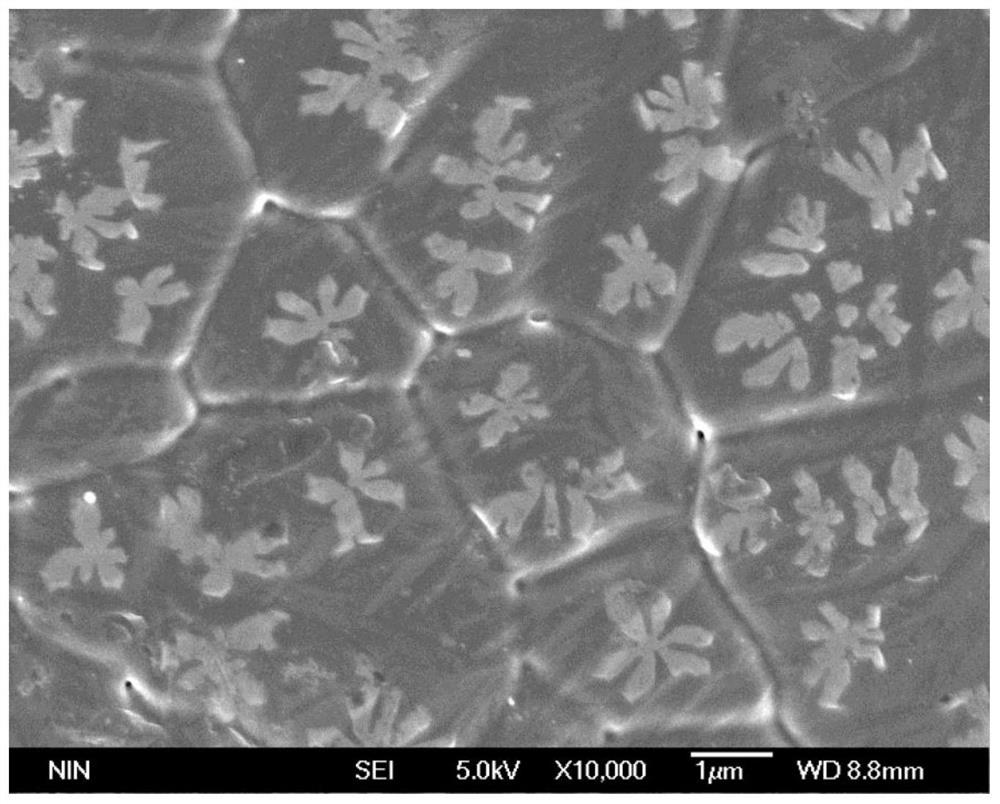

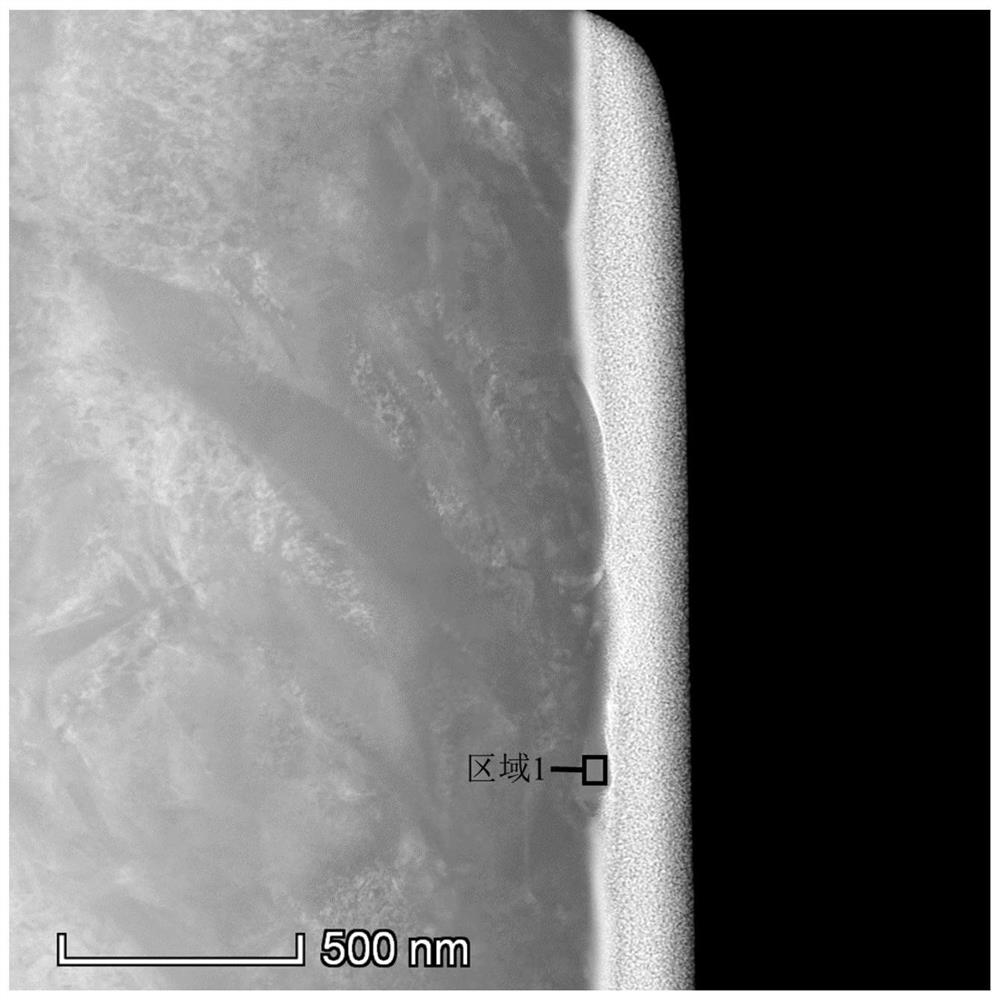

[0030] In this embodiment, the TC4 titanium alloy spherical powder surface is diffusely distributed with flake Y with an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Y 0.32%, O 0.12%, Al 5.95%, V 4.20%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0031] The surface is diffusely distributed with flake Y 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0032] Step 1, cleaning the rare earth metal Y of 0.06kg and the TC4 titanium alloy of 19.94kg respectively, and then mixing them to obtain mixed raw materials;

[0033] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomization equipment, and th...

Embodiment 2

[0056] In this embodiment, the TC4 titanium alloy spherical powder surface is diffusely distributed with flake Nd with an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Nd 0.12%, O0.08%, Al 6.20%, V 4.16%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0057] The surface is diffusely distributed with flake Nd 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0058] Step 1, the rare earth metal Nd of 0.02kg and the TC4 titanium alloy of 19.98kg are respectively cleaned, and then mixed to obtain mixed raw materials;

[0059] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomization equipment, and th...

Embodiment 3

[0064] In this embodiment, the TC4 titanium alloy spherical powder surface is dispersedly distributed with flake Gd having an equivalent diameter of 100nm to 1000nm and a thickness of 20nm to 50nm. 2 o 3 , the titanium alloy spherical powder is composed of the following elements by mass percentage: Gd 0.29%, O 0.10%, Al 5.76%, V 3.84%, the total amount of other impurity elements C, H and N is not more than 0.1%, and the balance is Ti ; where Al and V are alloying elements.

[0065] The surface is diffusely distributed with flake Gd 2 o 3 The preparation method of the TC4 titanium alloy spherical powder comprises the following steps:

[0066] Step 1, the rare earth metal Gd of 0.06kg and the TC4 titanium alloy of 19.94kg are respectively cleaned and processed, and then mixed to obtain mixed raw materials;

[0067] Step 2. Put the mixed raw materials obtained in Step 1 into the water-cooled copper crucible in the melting chamber of the vacuum induction melting gas atomizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com