A kind of 2,4-dinitroaniline preparation method

A technology for dinitroaniline and dinitrochlorobenzene is applied in the field of preparation of 2,4-dinitroaniline, and can solve the problems of ineffective utilization of ammonia, affecting the health of operators, and high production safety risks, and achieving Excellent product quality, controlled reaction rate, reduced production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

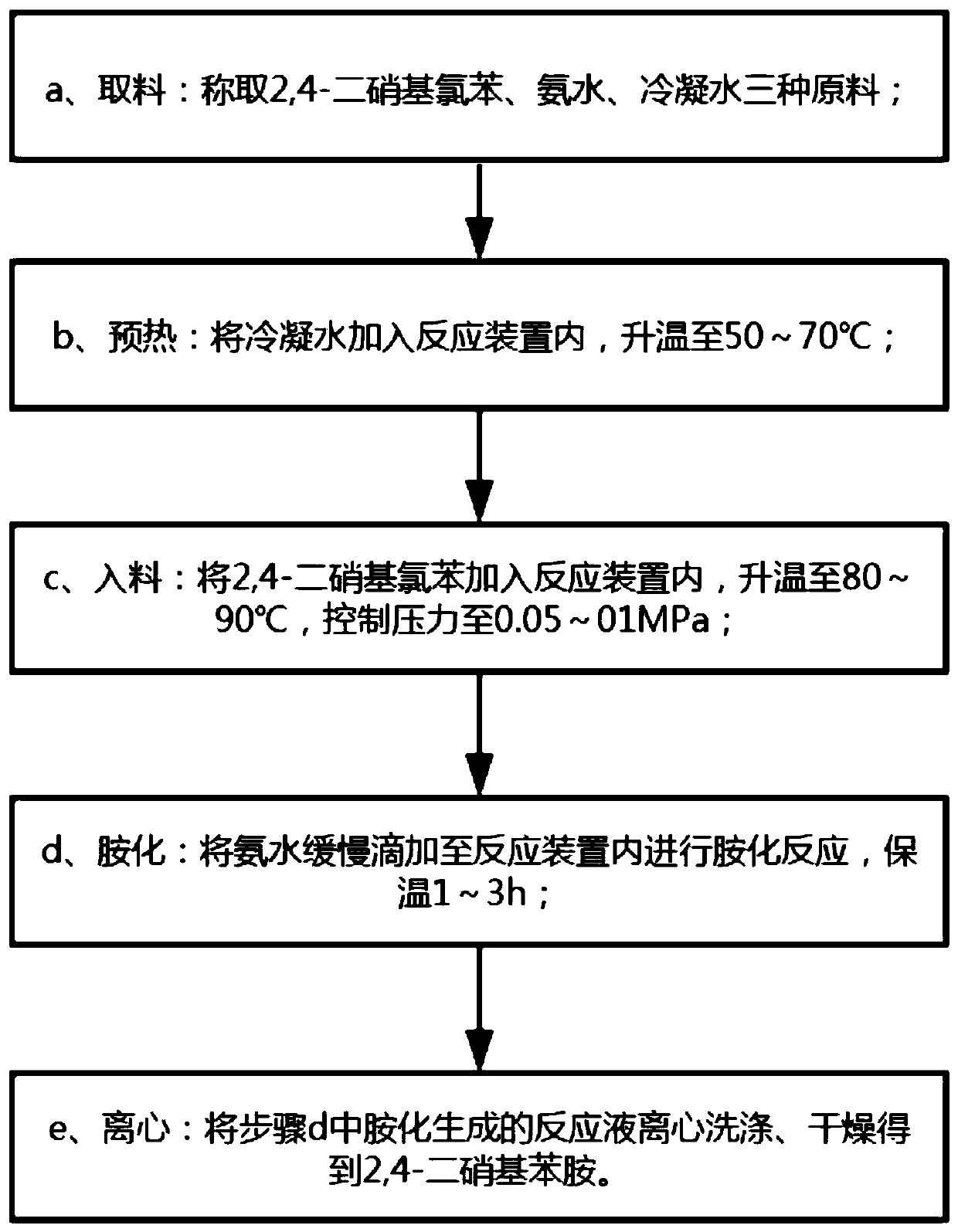

[0034] Such as Figure 1-7 Shown, a kind of 2,4-dinitroaniline preparation method comprises the following steps:

[0035] a, taking materials: take by weighing three kinds of raw materials of 2,4-dinitrochlorobenzene, ammonia water and condensed water;

[0036] b. Preheating: Add condensed water into the reaction device and raise the temperature to 50°C;

[0037] c. Feeding: Add 2,4-dinitrochlorobenzene into the reaction device, raise the temperature to 80°C, and control the pressure to 0.05-0.1MPa;

[0038] d. Amination: Slowly add ammonia water dropwise to the reaction device for amination reaction, keep warm for 1;

[0039] e. Centrifugation: centrifuge, wash and dry the reaction solution generated by the amination in step d to obtain 2,4-dinitroaniline.

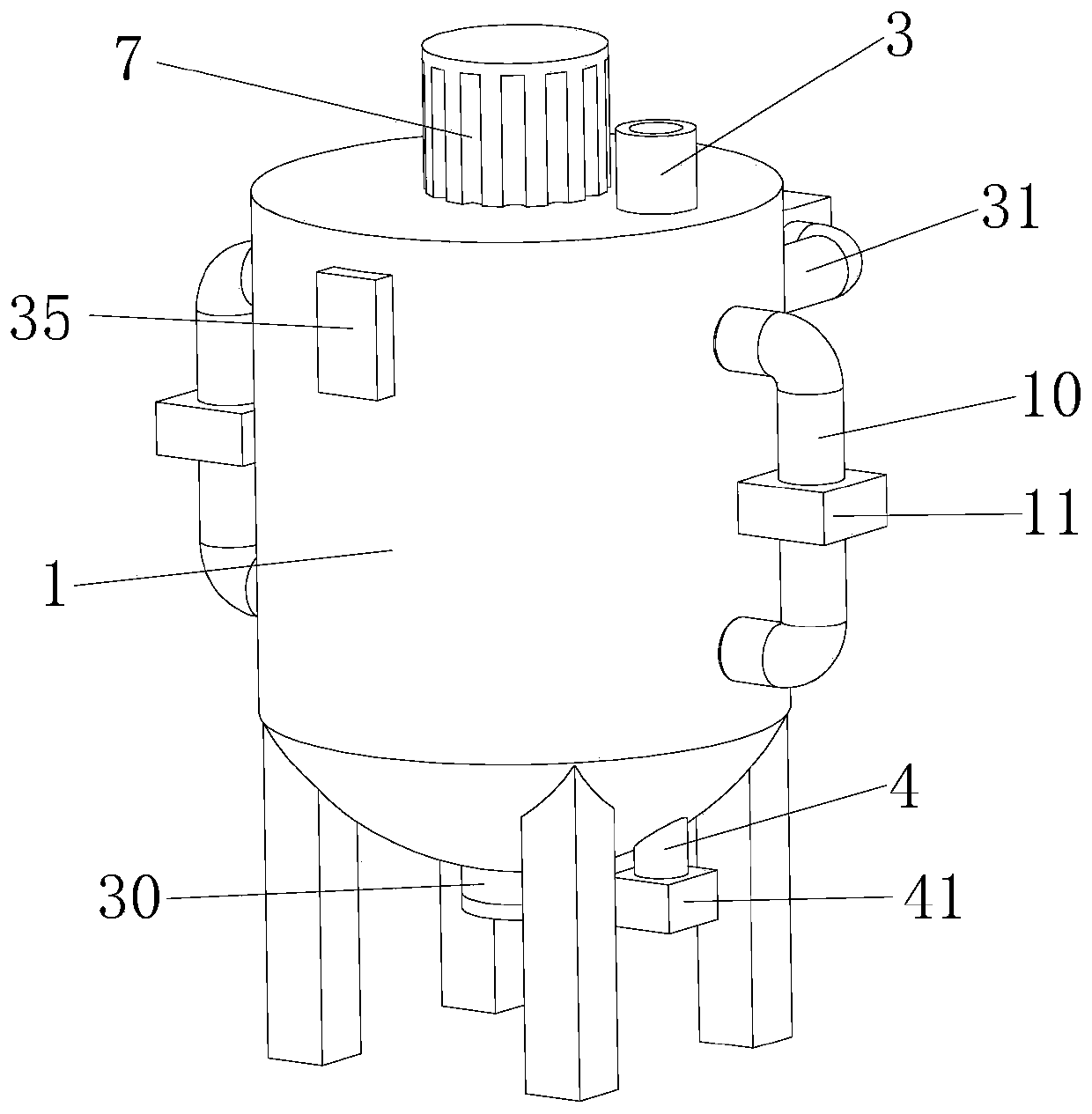

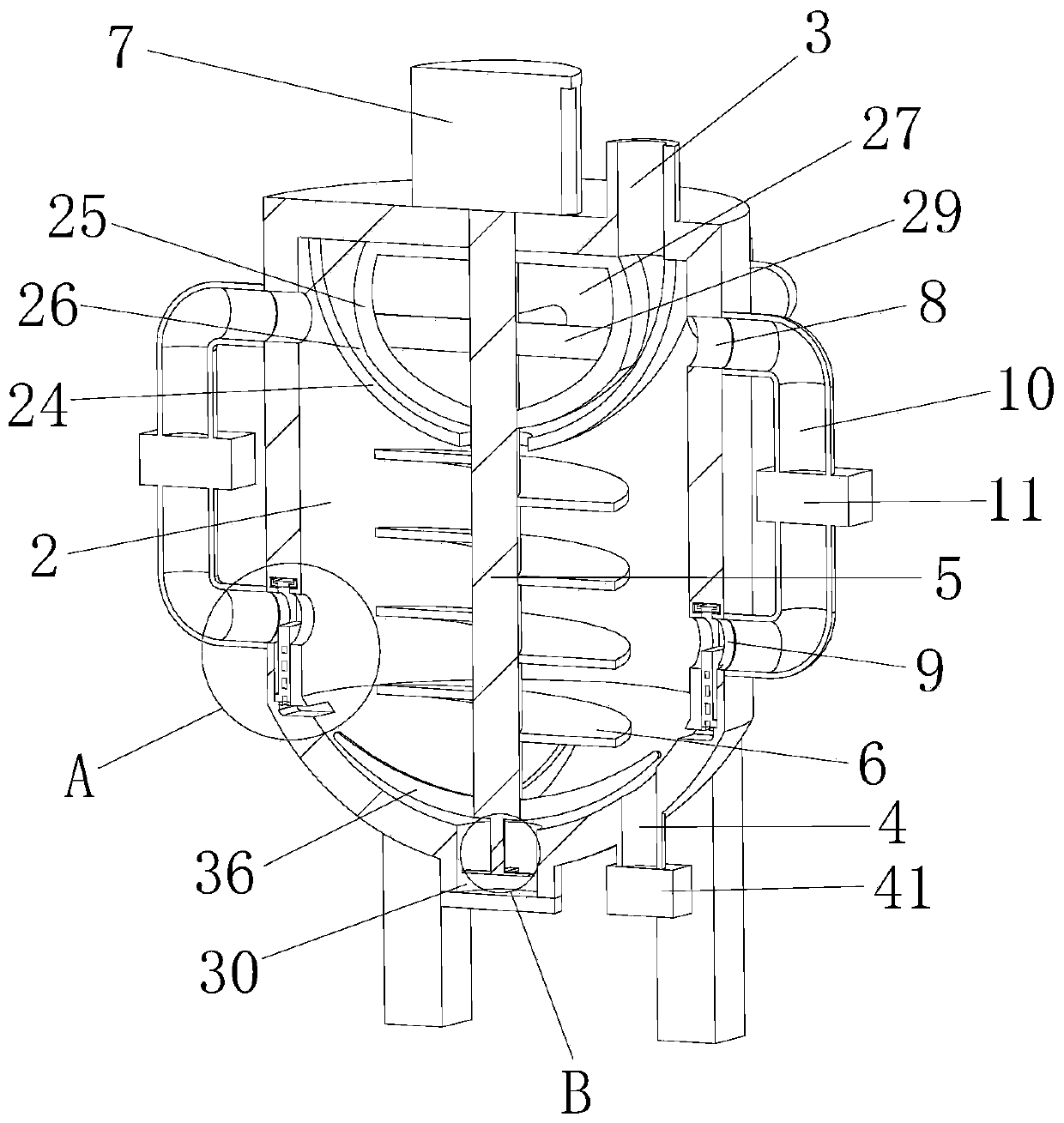

[0040]Wherein, the reaction device in the step b comprises a reaction cylinder 1, which has a reaction chamber 2 in the reaction cylinder 1, and a feed pipe 3 and an ammonia addition pipe 4 communicating with the react...

Embodiment 2

[0055] Such as figure 1 Shown, a kind of 2,4-dinitroaniline preparation method comprises the following steps:

[0056]a, taking materials: take by weighing three kinds of raw materials of 2,4-dinitrochlorobenzene, ammonia water and condensed water;

[0057] b. Preheating: Add condensed water into the reaction device and raise the temperature to 70°C;

[0058] c. Feeding: Add 2,4-dinitrochlorobenzene into the reaction device, raise the temperature to 90°C, and control the pressure to 0.1MPa;

[0059] d. Amination: Slowly add ammonia water dropwise to the reaction device for amination reaction, and keep warm for 3 hours;

[0060] e. Centrifugation: centrifuge, wash and dry the reaction solution generated by the amination in step d to obtain 2,4-dinitroaniline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com