Post-extraction technology of chicken alpha-disruptor

An extraction process and interferon technology, applied in the field of post-extraction process of chicken alpha-interferon, can solve problems such as high cost, low yield, complicated production process, etc., and achieve mild elution conditions, environmental protection, cost, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

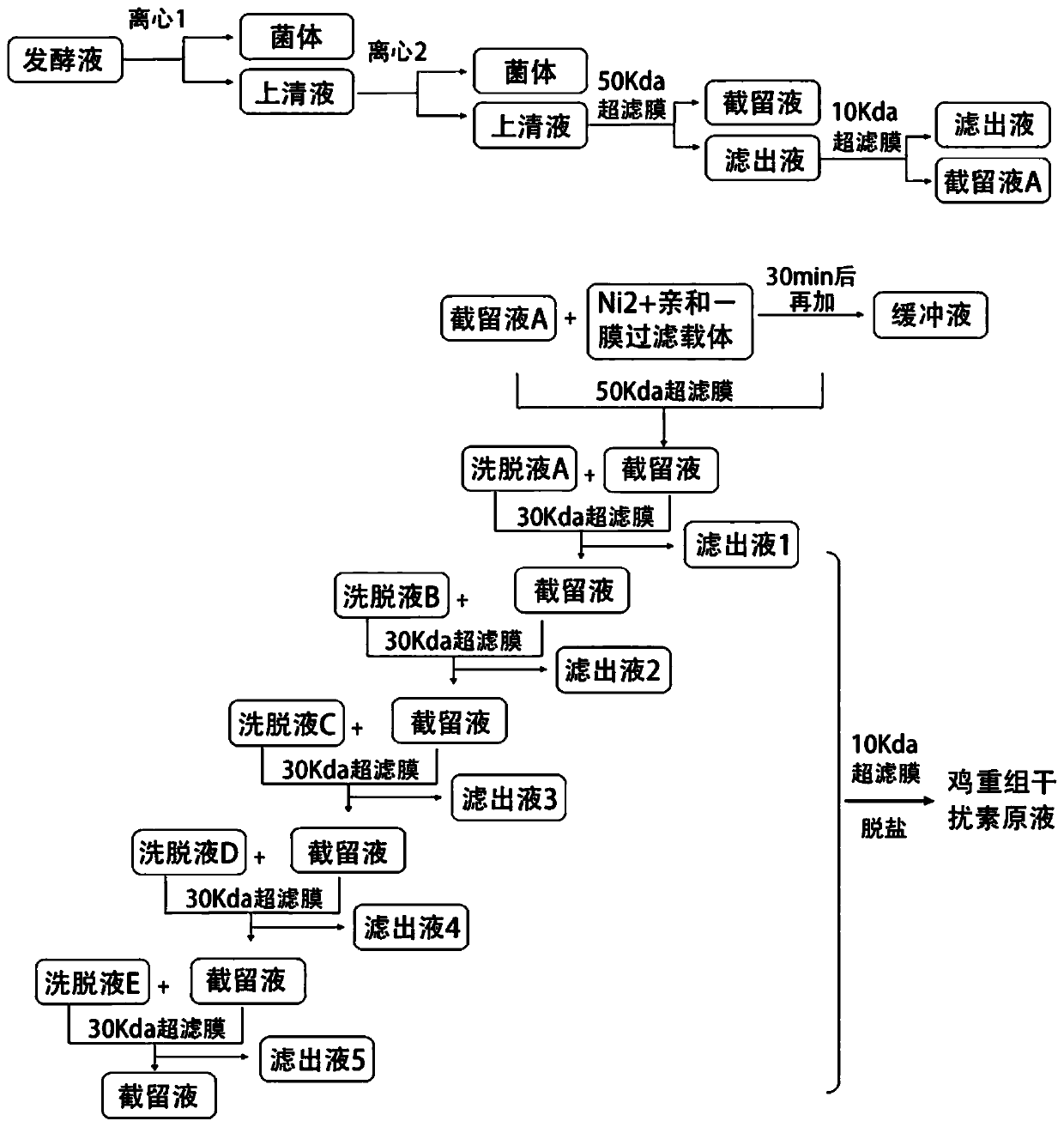

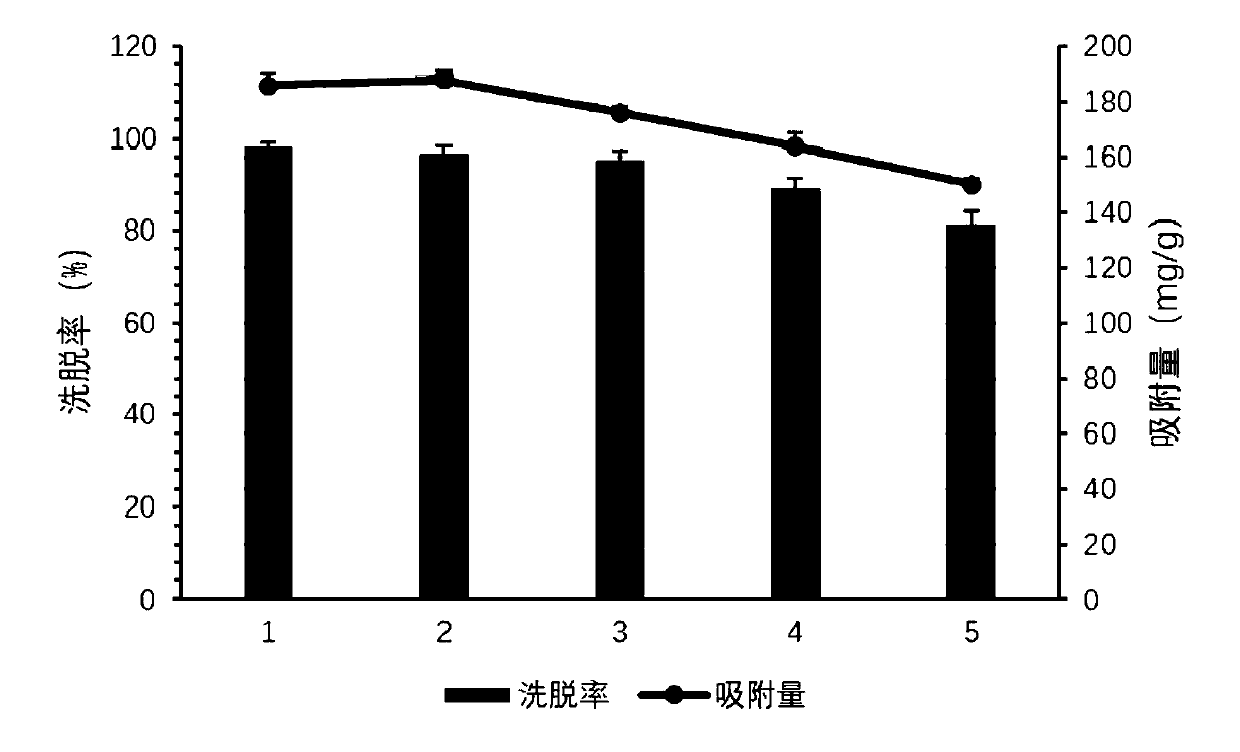

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1. The present invention produces the construction of the engineered bacterium of recombinant chicken α-interferon

[0079] Step 1. Obtaining the target gene

[0080] We found the original gene sequence of α-interferon of red jungle fowl (SEQ ID NO.3) on NCBI, deleted the original signal peptide of α-interferon of red jungle fowl, and counted the amino acids with degenerate codons Analysis and selection of codons with high usage frequency to obtain a new recombinant chicken α-interferon gene sequence (SEQ ID NO.1), entrust Sangon Bioengineering (Shanghai) Co., Ltd. to perform whole gene synthesis to obtain the target gene.

[0081] Design primers, add EcoR I restriction site to the 5' end of the target gene, and add Not I restriction site to the 3' end by PCR reaction. After the PCR product was subjected to 1.5% agarose gel electrophoresis, a 513bp fragment was recovered with a DNA purification and recovery kit. The DNA sequence of the fragment is shown in S...

Embodiment 2

[0107] Embodiment 2. The fermentation process of recombinant chicken α-interferon

[0108] 1. Screening of multi-copy strains

[0109] Streak-inoculate the single colonies of positive clones obtained in Example 1 onto YPD solid medium containing 300 μg / ml, 600 μg / ml, and 900 μg / ml bleomycin in sequence, and screen out stable multi-copy high-yielding strains. Specific steps are as follows:

[0110] Inoculate the single colonies of positive clones on the YPD plate containing 100 μg / ml bleomycin to the YPD selective plate medium containing 300 μg / ml bleomycin using the “three-step streaking method” and culture at 30°C for 3-5 days. Colonies were observed after days.

[0111] Inoculate a single colony with good growth on the YPD plate containing 300 μg / ml bleomycin to the YPD selective plate medium containing 600 μg / ml bleomycin using the “three-step streaking method” and culture at 30°C for 3- Colonies were observed after 5 days.

[0112] Inoculate a single colony with good g...

Embodiment 3

[0129] Embodiment 3. Post-extraction process of chicken alpha-interferon

[0130] Step 1: Put the jar

[0131] First, the preserved recombinant Pichia strain (CCTCC M 2019748) is carried out according to the method of Example 2 for the screening of multi-copy strains, primary seed culture, secondary seed cultivation, and then the secondary seed liquid is pressed by 15% (v / v ) is transferred to 15T (tons) BMMY liquid medium for fermentation and cultivation (method is the same as in Example 2), and the Pichia fermented liquid is obtained. The chicken α-interferon quantitative detection kit was used to measure the concentration of the recombinant chicken α-interferon in the fermentation liquid of Pichia pastoris, and the concentration of the chicken α-interferon in the fermentation liquid was measured to be 20-22 g / L.

[0132] Step 2: Centrifuge

[0133] Centrifuge the fermented liquid in the storage tank through a centrifuge, the centrifuge speed is 12000rpm, and the centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com