Method for preparing high-strength hydrogel based on tanning principle

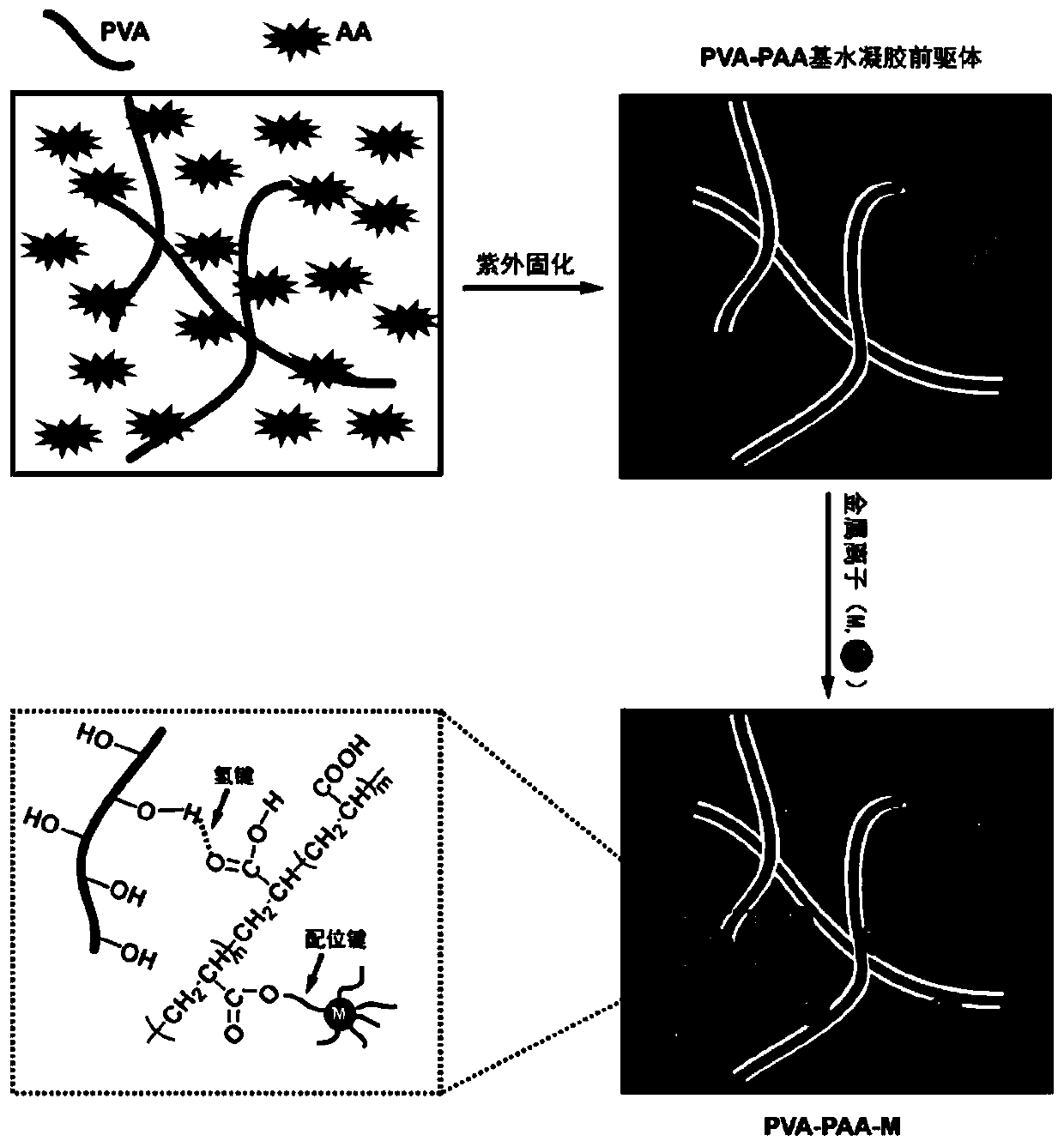

A hydrogel and high-strength technology, which is applied in the field of preparing high-strength hydrogel based on the principle of leather tanning, can solve the problems of difficult large-scale preparation, complex synthesis methods, and high cost, and achieve uniform immersion promotion, simple preparation process, and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, preparation of PVA-PAA-based hydrogel precursor

[0033] Step 101. Dissolve 5 parts of polyvinyl alcohol in 116.5 parts of deionized water in parts by mass, then raise the temperature to 60°C and stir for 1.5 hours, then cool to 20°C to obtain a clear and transparent PVA aqueous solution; the polyvinyl alcohol Molecular weight M w =205,000;

[0034]Step 102: Add 50 parts by mass of acrylic acid monomer and 0.25 parts of 2,4-dihydroxybenzophenone to the PVA aqueous solution obtained in Step 101, and then stir at 20°C for 16 minutes to obtain PVA - AA mixture;

[0035] Step 103. Put the PVA-AA mixture obtained in step 102 under vacuum for 15 minutes, then pour it into a glass mold, and perform ultraviolet curing to polymerize the acrylic acid monomer to obtain a PVA-PAA-based hydrogel precursor The size of the glass mold is 10cm×10cm (length×width); the UV light used in the UV curing has a wavelength of 365nm, a power of 40W, a temperature of 20°C, and a time o...

Embodiment 2

[0051] Step 1, preparation of PVA-PAA-based hydrogel precursor

[0052] Step 101. Dissolve 1 part of polyvinyl alcohol in 23.3 parts of deionized water in parts by mass, then raise the temperature to 90°C and stir for 1 hour, then cool to 22°C to obtain a clear and transparent PVA aqueous solution; the molecular weight of the polyvinyl alcohol m w =205,000;

[0053] Step 102: Add 9 parts by mass of acrylic acid monomer and 0.045 parts of α-ketoglutaric acid to the PVA aqueous solution obtained in Step 101, and then stir at 22°C for 10 minutes to obtain a PVA-AA mixed solution ;

[0054] Step 103. Put the PVA-AA mixture obtained in step 102 under vacuum for 10 minutes, then pour it into a glass mold, and perform ultraviolet curing to polymerize the acrylic acid monomer to obtain a PVA-PAA-based hydrogel precursor The size of the glass mold is 10cm×10cm (length×width); the UV light used in the UV curing has a wavelength of 365nm, a power of 40W, a temperature of 22°C, and a t...

Embodiment 3

[0060] Step 1, preparation of PVA-PAA-based hydrogel precursor

[0061] Step 101. Dissolve 10 parts of polyvinyl alcohol in 233 parts of deionized water in parts by mass, then raise the temperature to 70°C and stir for 2 hours, then cool to 25°C to obtain a clear and transparent PVA aqueous solution; the molecular weight of the polyvinyl alcohol m w =205,000;

[0062] Step 102: Add 90 parts by mass of acrylic acid monomer and 0.45 parts of α-hydroxyalkyl phenone to the PVA aqueous solution obtained in Step 101, and then stir at 25°C for 20 minutes to obtain a PVA-AA mixed liquid;

[0063] Step 103. Put the PVA-AA mixture obtained in step 102 under vacuum for 20 minutes, then pour it into a glass mold, and perform ultraviolet curing to polymerize the acrylic acid monomer to obtain a PVA-PAA-based hydrogel precursor The size of the glass mold is 10cm×10cm (length×width); the UV light used in the UV curing has a wavelength of 365nm, a power of 40W, a temperature of 25°C, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com