Continuous pyrolysis gasification system and method

A technology of pyrolysis gasification and pyrolysis gas, which is applied in the field of continuous pyrolysis gasification system, can solve the problems of energy waste, environmental pollution, and the incineration waste treatment process cannot be well adapted to the requirements of industrialization, so as to reduce pollution, The effect of efficient resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

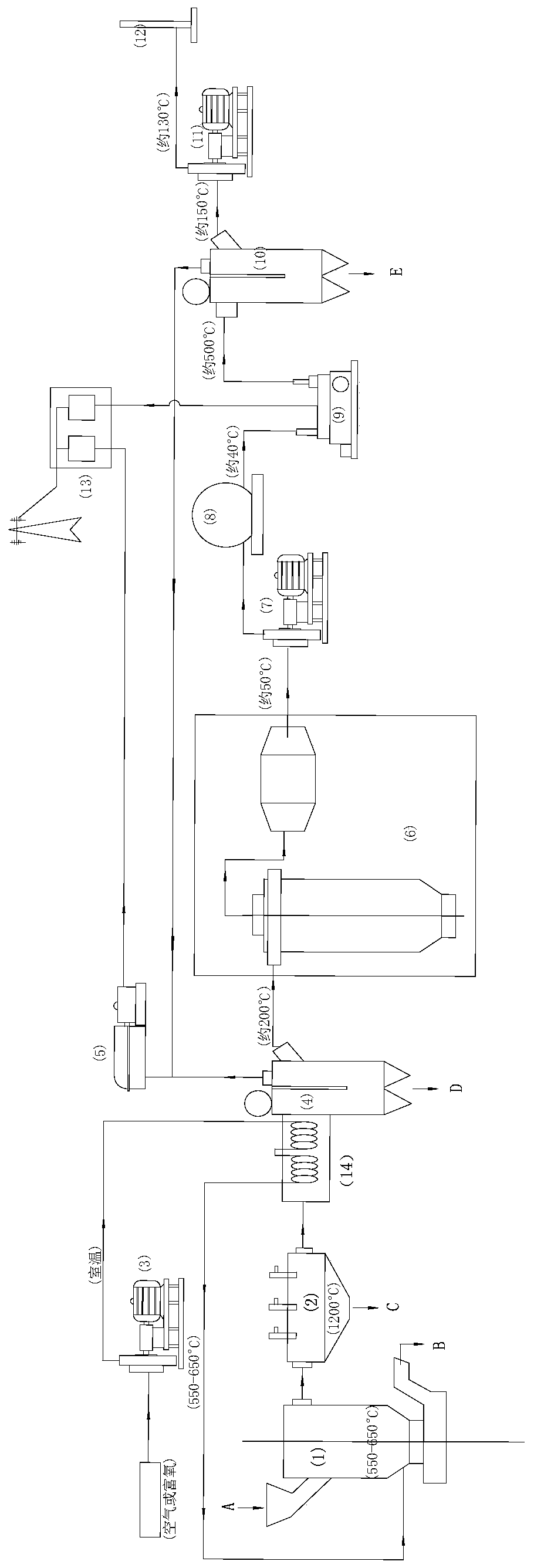

[0065] Such as figure 1 As shown, this embodiment provides a continuous pyrolysis gasification system. In this system, the blower 3 is a frequency conversion fan, and the gasification medium is sequentially transported to the composite waste heat boiler 4 through the blower 3. The gasification of the composite waste heat boiler 4 After being heated by the medium heater, it enters the gasifier 1 to provide the gasification medium and heat;

[0066] The garbage material enters the gasifier 1 through the material input port A, and is pyrolyzed and gasified in the gasifier 1. The crude synthesis gas produced by the pyrolysis gasification enters the subsequent system sequentially under the gravity of the syngas booster fan 7, The residue after the pyrolysis and gasification of the material is discharged from the slag outlet B at the bottom of the gasifier 1;

[0067] The plasma chamber 2 works with plasma to generate a high temperature of 1200 degrees Celsius. The synthesis gas pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com