Organophosphorus compound sensor and preparation method thereof

A compound and organophosphorus technology, applied in the field of chemical sensors, can solve the problems of poor selectivity, complex preparation methods, poor stability, etc., and achieve the effects of good sensitivity and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An organophosphorus compound sensor is composed of a gold interdigitated electrode and a functional conductive polymer film deposited on its surface, and its preparation steps are as follows:

[0034] (1) Dry the gold interdigitated electrode after cleaning: wash with detergent, deionized water, acetone, dichloromethane and isopropanol in sequence under the action of ultrasound, and the washing time is 15 minutes each time; among them, the gold interdigitated electrode The finger length is 1400 μm, the finger width is 5 μm, the interdigital spacing is 3 μm, and the number of interdigital pairs is 60;

[0035] (2) FeCl 3 The solution was dropped on the gold interdigitated electrode, and the FeCl was obtained by the spin-coating method 3 Membrane, rotating speed is 6000rpm, time is 60s; Among them, FeCl 3 The mass concentration (c) of solution is 9wt%, and solvent is n-butanol, FeCl 3 The thickness (h1) of the film is 103 nm;

[0036] (3) will be coated with FeCl 3 T...

Embodiment 2~15

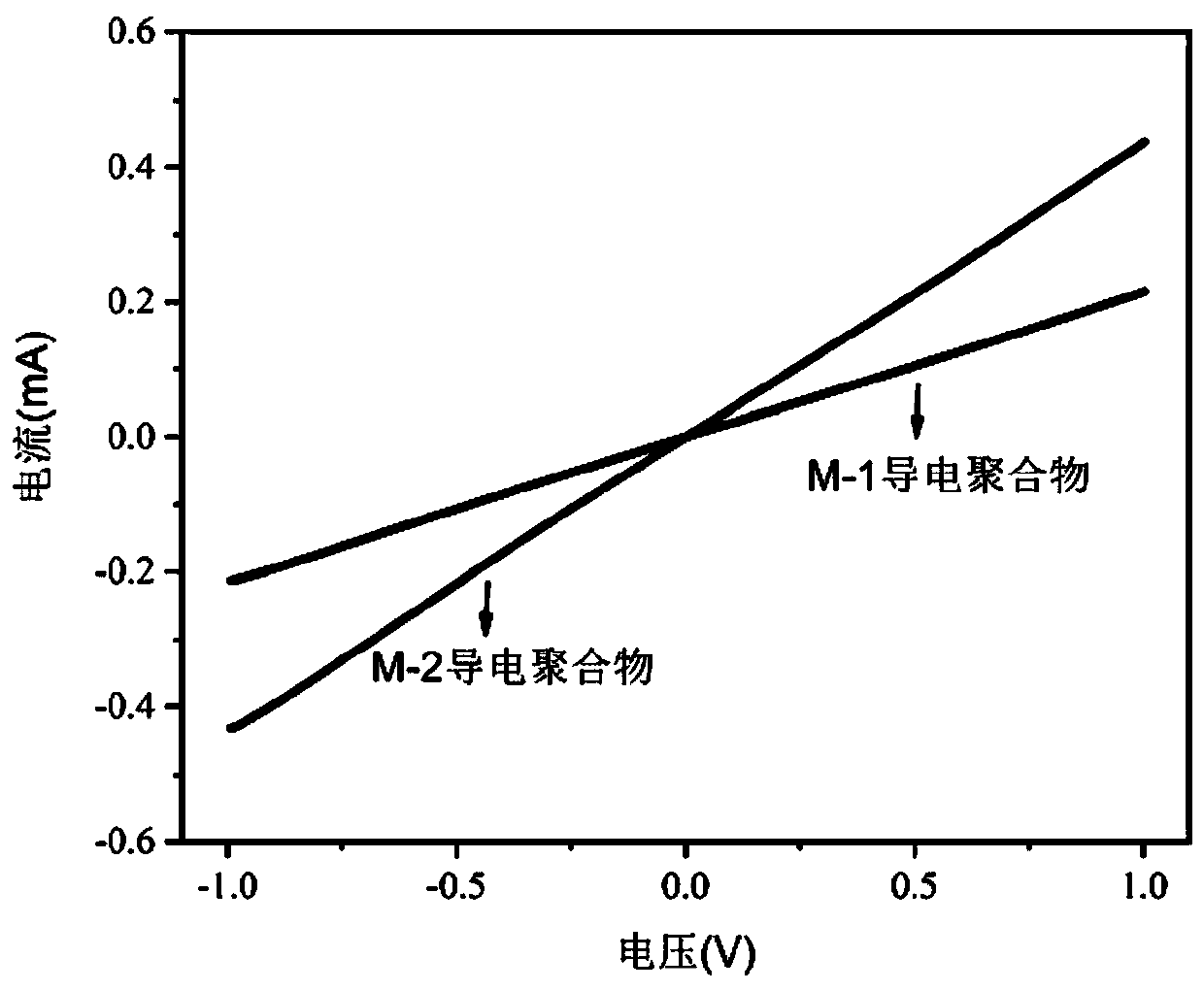

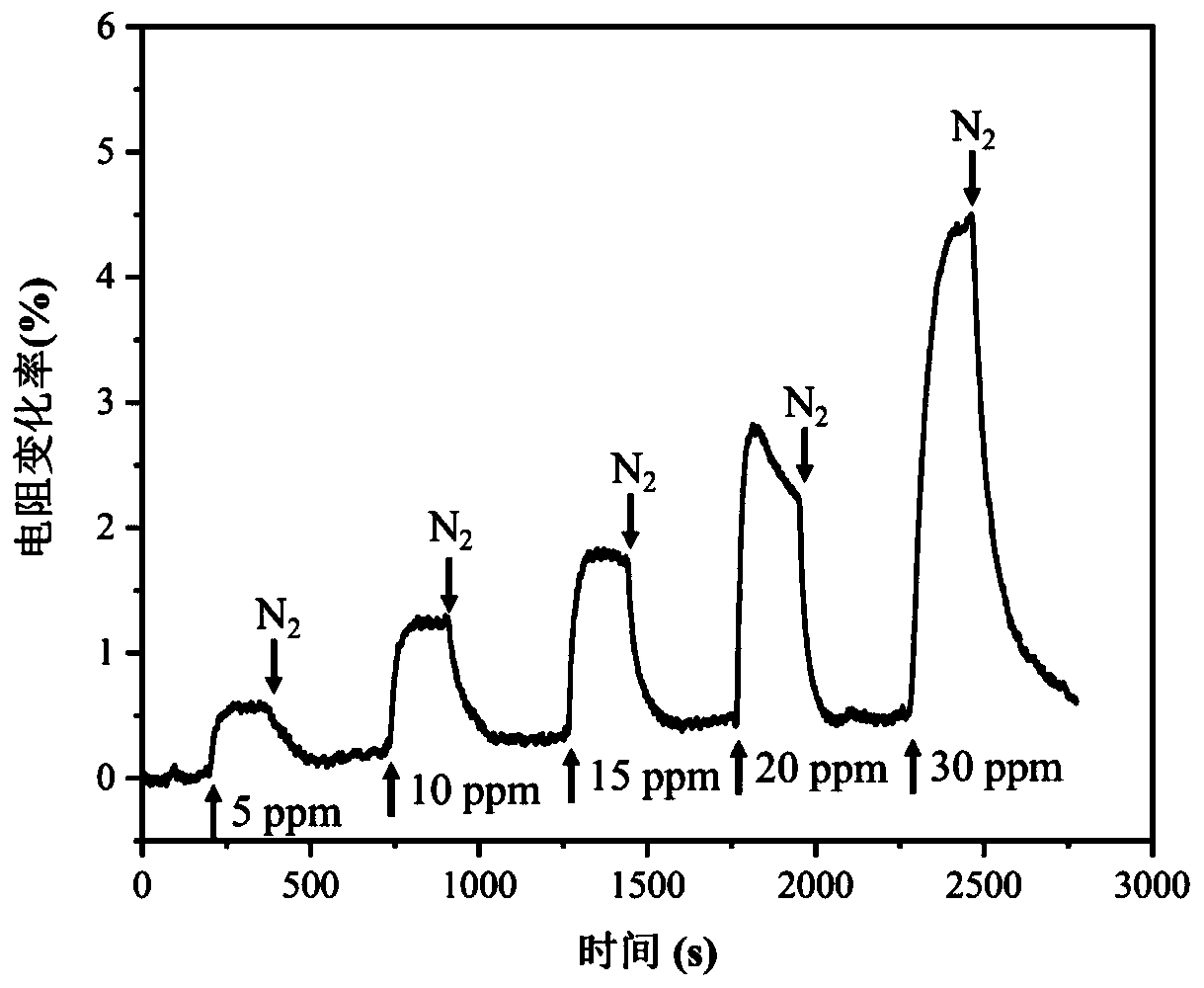

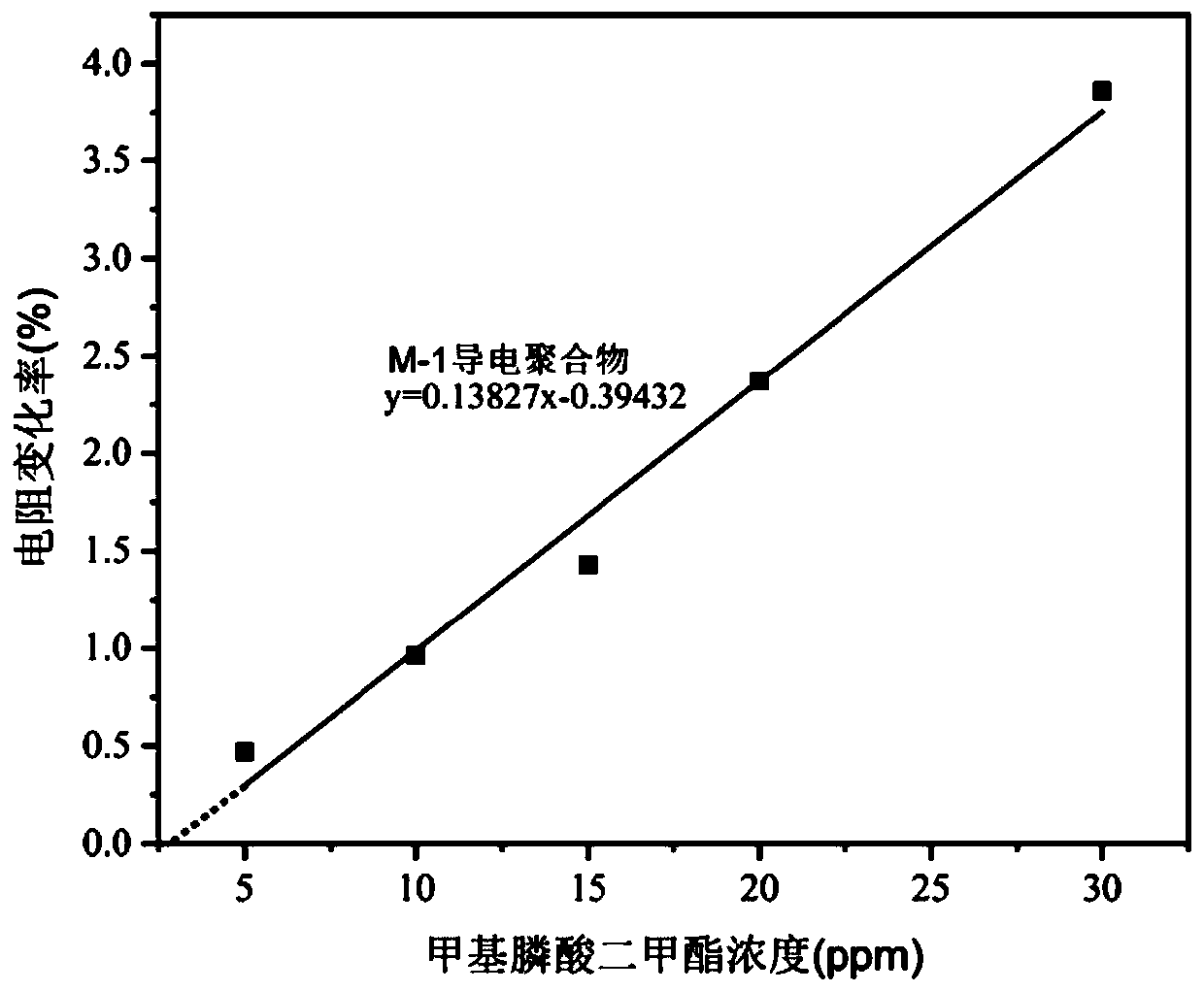

[0044] An organophosphorus compound sensor, the preparation method of Examples 2-15 is basically the same as that of Example 1, the difference is that the parameters in the preparation process are different, see Table 1 for details, wherein, M represents a functionalized conductive polymer, see for details Table 2, the performance indicators of the obtained organophosphorus compound sensor are shown in Table 4; wherein, the organophosphorus compound sensor obtained in Example 5 is selected for conductivity test and cyclic response test, and the results are as follows figure 1 with Figure 4 shown, where N 2 It means that the sensor is desorbed with nitrogen gas at this place.

[0045] The preparation parameter of table 1 embodiment 2~15

[0046]

[0047]

[0048] Table 2 The number and molecular formula of the functionalized conductive polymer monomer

[0049]

[0050]

Embodiment 16~20

[0052] An organophosphorus compound sensor, the preparation method of Examples 16-20 is basically the same as that of Example 1, the difference is that the parameters of step (1) in the preparation process are different, see Table 3 for details, the prepared organophosphorus compound sensor The performance indicators are shown in Table 4.

[0053] The preparation parameter of table 3 embodiment 16~20

[0054]

[0055] Table 4 Performance parameters of organophosphorus compound sensors

[0056]

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| interdigital gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com