Electrode substrate for transparent light-emitting device display, and manufacturing method therefor

A technology for light-emitting devices and displays, applied in semiconductor/solid-state device manufacturing, transparent dielectrics, equipment for manufacturing conductive/semiconductive layers, etc., can solve problems such as high production costs, large-scale acquisition of indium, restrictions, etc., and achieve reduction The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0078] Hereinafter, exemplary embodiments described in this specification will be illustrated by way of examples. However, this is not intended to limit the scope of the exemplary embodiments by example.

[0079]

Embodiment 1

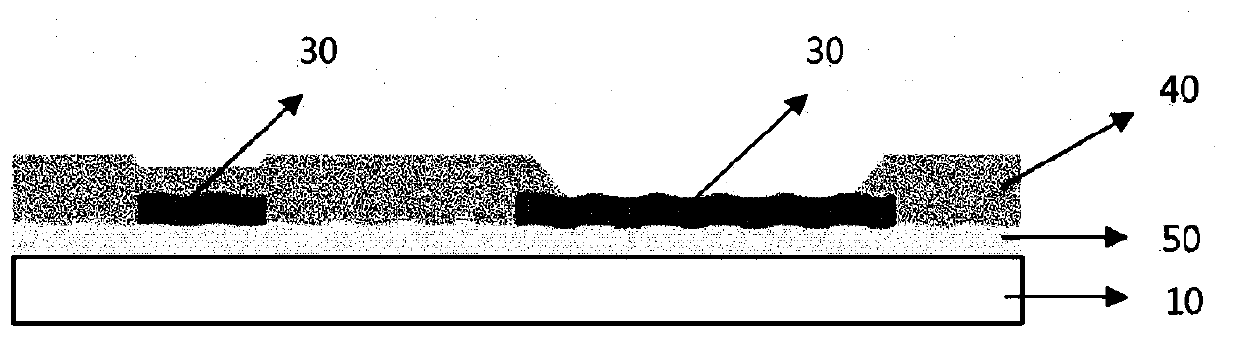

[0081] A urethane acryl-based transparent adhesive was applied on a PET film with a thickness of 250 μm by using a comma coater, followed by drying with hot air at 100° C. for 5 minutes to form an adhesive layer with a thickness of 10 μm. A PET film provided with a transparent adhesive layer and a copper foil having a thickness of 3 μm were subjected to hot roll lamination at 120° C. and 1.4 meters per minute (mpm).

[0082] A dry film resist (DFR) was laminated on the copper foil surface of the copper foil-laminated film, and then a Voronoi-style DFR pattern with a line width of 20 μm was formed through an exposure and development process.

[0083] The exposed copper foil was removed by using a ferric chloride-based copper etchant, and the DFR pattern was peeled off to form a Voronoi-style copper foil pattern. In this case, the haze of the area where the copper foil pattern was not provided was 40%.

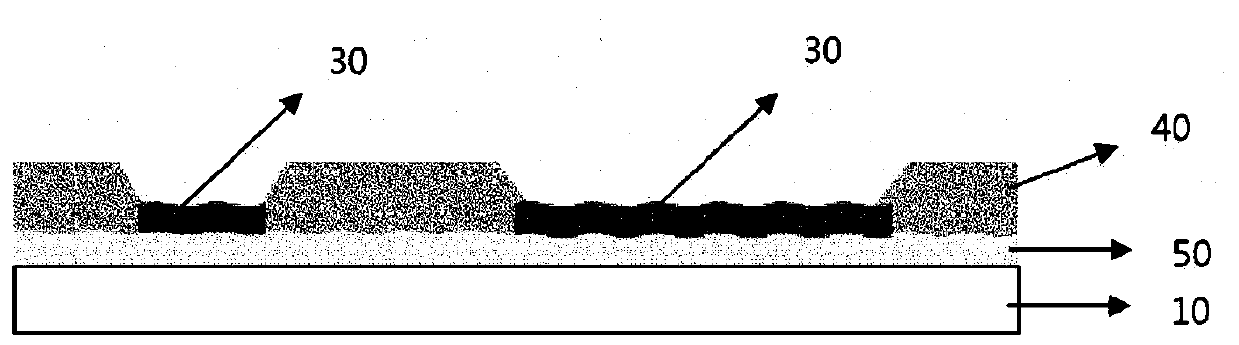

[0084] The negative transparent photosensitive resin composition was appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com