A kind of coarse polypropylene-basalt hybrid fiber prefabricated dry hard fiber concrete, pipe jacking and manufacturing method

A fiber-reinforced concrete and polypropylene fiber technology, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems that the components cannot achieve the expected effect, have no manufacturing method, and have not noticed, etc., and achieve less investment in molds, The effect of reducing the amount of cement and suppressing the occurrence of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment one, for concrete for jacking pipe, it must Higher strength, better crack resistance ; At the same time, during construction, it must withstand high-frequency vibration, Therefore, it must have better cohesion to concrete .

[0063] Therefore, the application carried out when researching the mix ratio:

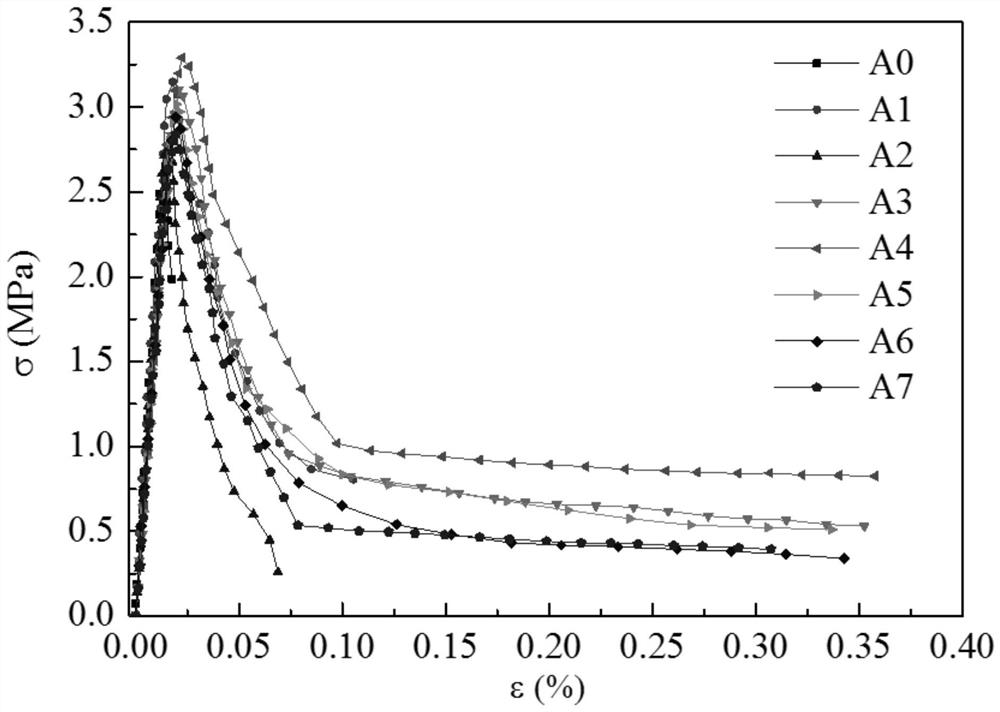

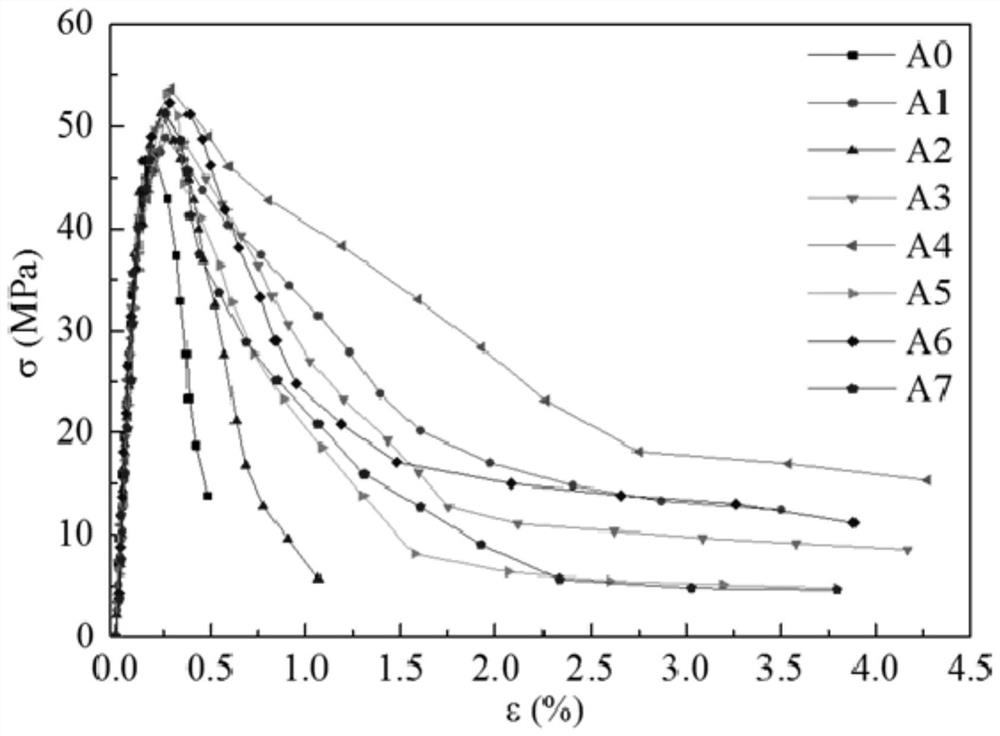

[0064] 1) Axial compression test of fiber reinforced concrete;

[0065] 2) axial tension test of fiber reinforced concrete;

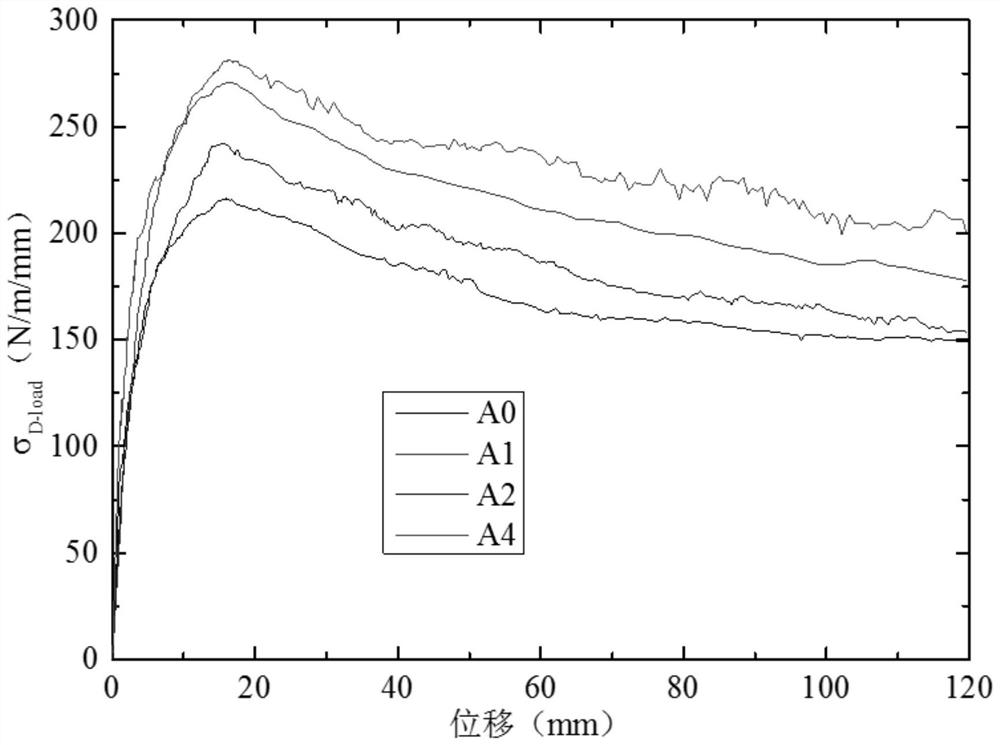

[0066] 3) Three-point test: comparison of load-displacement curves of pipe joints, crack propagation process of pipe joints, and post-crack strength analysis.

[0067] The cohesion of the concrete used for mandrel vibration is extremely important. The selection of concrete materials and the mix ratio should be based on the improvement of the cohesion of the concrete as the main performance requirement. It has the advantages of high stability, easy forming of the nozzle and good compactness, and no water after the nozzle is rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com